rubber composition

A rubber composition, rubber technology, applied in the direction of transportation and packaging, special tires, tire parts, etc., can solve the problems of low affinity, increased cohesion, insufficient effect, etc., to achieve excellent wear resistance, improve tensile properties and The effect of viscoelastic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

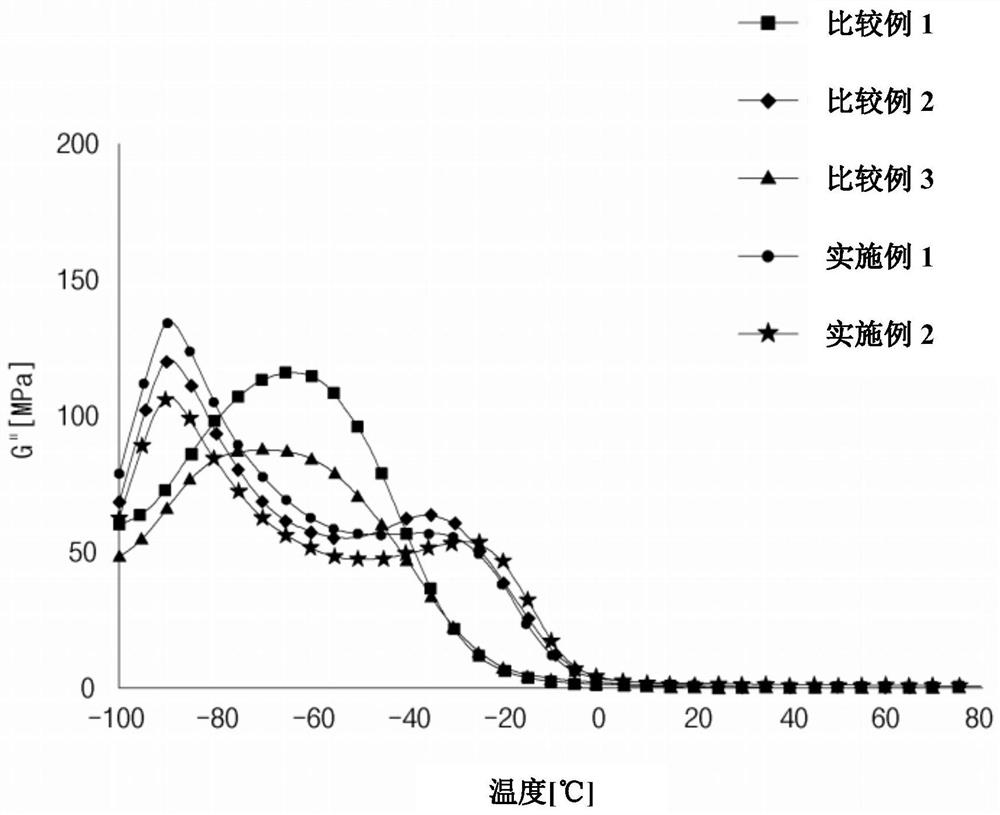

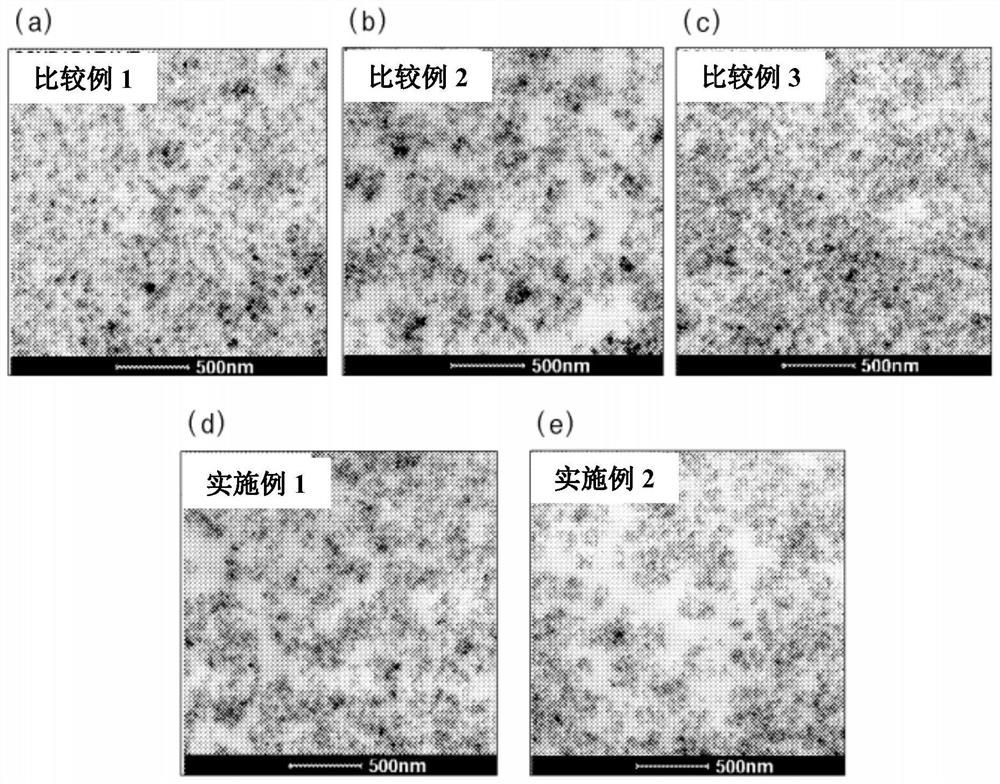

Embodiment 1

[0092] 63 parts by weight of solution polymerized styrene-butadiene rubber at both ends (styrene content is 39 weight %, vinyl content is 25 weight %, extender oil content is 5 weight %) (MF3925, LG Chem.), 40 parts by weight of rare earth catalyzed butadiene rubber (cis bond content of 96% by weight), 70 parts by weight of silica, 5.6 parts by weight of coupling agent, 27.0 parts by weight of processing oil, 3 Parts by weight of zinc oxide and 1 part by weight of stearic acid were mixed to prepare a first compounded product, and 1.5 parts by weight of sulfur powder and 2.8 parts by weight of a vulcanization accelerator were mixed therewith to prepare a rubber composition. In this case, the solubility parameter difference (Δ) between solution polymerized two-end modified styrene-butadiene rubber and rare earth catalyzed butadiene rubber was 0.89 (solution polymerized two-end modified styrene-butadiene rubber). Solubility parameter of styrene-butadiene rubber = 18.06, solubilit...

Embodiment 2

[0094] 63 parts by weight of solution polymerized styrene-butadiene rubber at both ends (styrene content is 43 weight %, vinyl content is 25 weight %, extender oil content is 5 weight %) (MF4325, LG Chem.), 40 parts by weight of rare earth catalyzed butadiene rubber (cis bond content of 96% by weight), 70 parts by weight of silica, 5.6 parts by weight of coupling agent, 27.0 parts by weight of processing oil, 3 Parts by weight of zinc oxide and 1 part by weight of stearic acid were mixed to prepare a first compounded product, and 1.5 parts by weight of sulfur powder and 2.8 parts by weight of a vulcanization accelerator were mixed therewith to prepare a rubber composition. In this case, the solubility parameter difference (Δ) between solution polymerized two-end modified styrene-butadiene rubber and rare earth catalyzed butadiene rubber is 1.00 (solution polymerized two-end modified styrene-butadiene rubber Solubility parameter of styrene-butadiene rubber = 18.17, solubility p...

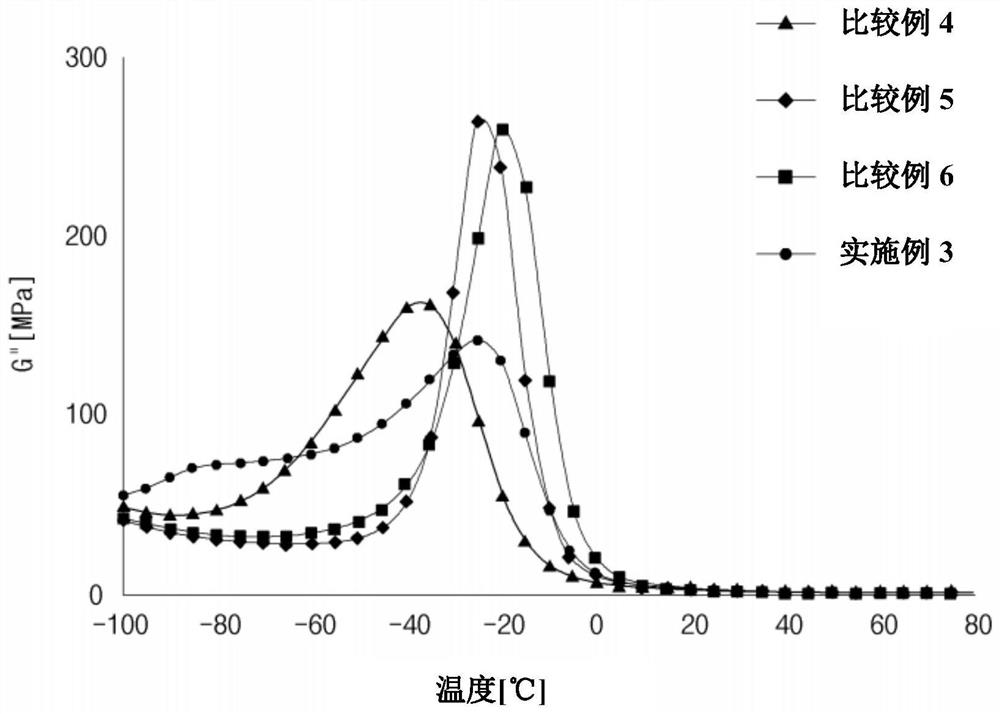

Embodiment 3

[0096] 84 parts by weight of solution polymerized styrene-butadiene rubber at both ends (styrene content is 39 weight %, vinyl content is 25 weight %, extender oil content is 5 weight %) (MF3925, LG Chem.), 20 parts by weight of rare earth catalyzed butadiene rubber (cis bond content of 96% by weight), 100 parts by weight of silica, 8.0 parts by weight of coupling agent, 36.0 parts by weight of processing oil, 3 Parts by weight of zinc oxide and 1 part by weight of stearic acid were mixed to prepare a first compounded product, and 1.5 parts by weight of sulfur powder and 2.8 parts by weight of a vulcanization accelerator were mixed therewith to prepare a rubber composition. In this case, the solubility parameter difference (Δ) between solution polymerized two-end modified styrene-butadiene rubber and rare earth catalyzed butadiene rubber was 0.89 (solution polymerized two-end modified styrene-butadiene rubber). Solubility parameter of styrene-butadiene rubber = 18.06, solubili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com