An improved biosynthetic resin

A synthetic resin and improved technology, which is applied in the field of control of biomass micropowder particle size, surface morphology and surface functional groups, can solve the problems that the product performance cannot meet the requirements of use, and achieve the improvement of mechanical properties and stability, and strong reliability Degradability, strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific embodiment 1: An improved biosynthetic resin according to this embodiment, which includes a biomass micropowder composition with a mass fraction of 30-60%, a resin with a mass fraction of 12-50%, and a phase with a mass fraction of 0.5-5%. Compatible agent, synthetic resin lubricant with a mass fraction of 0.5-3% and inorganic filler with a mass fraction of 5-20%;

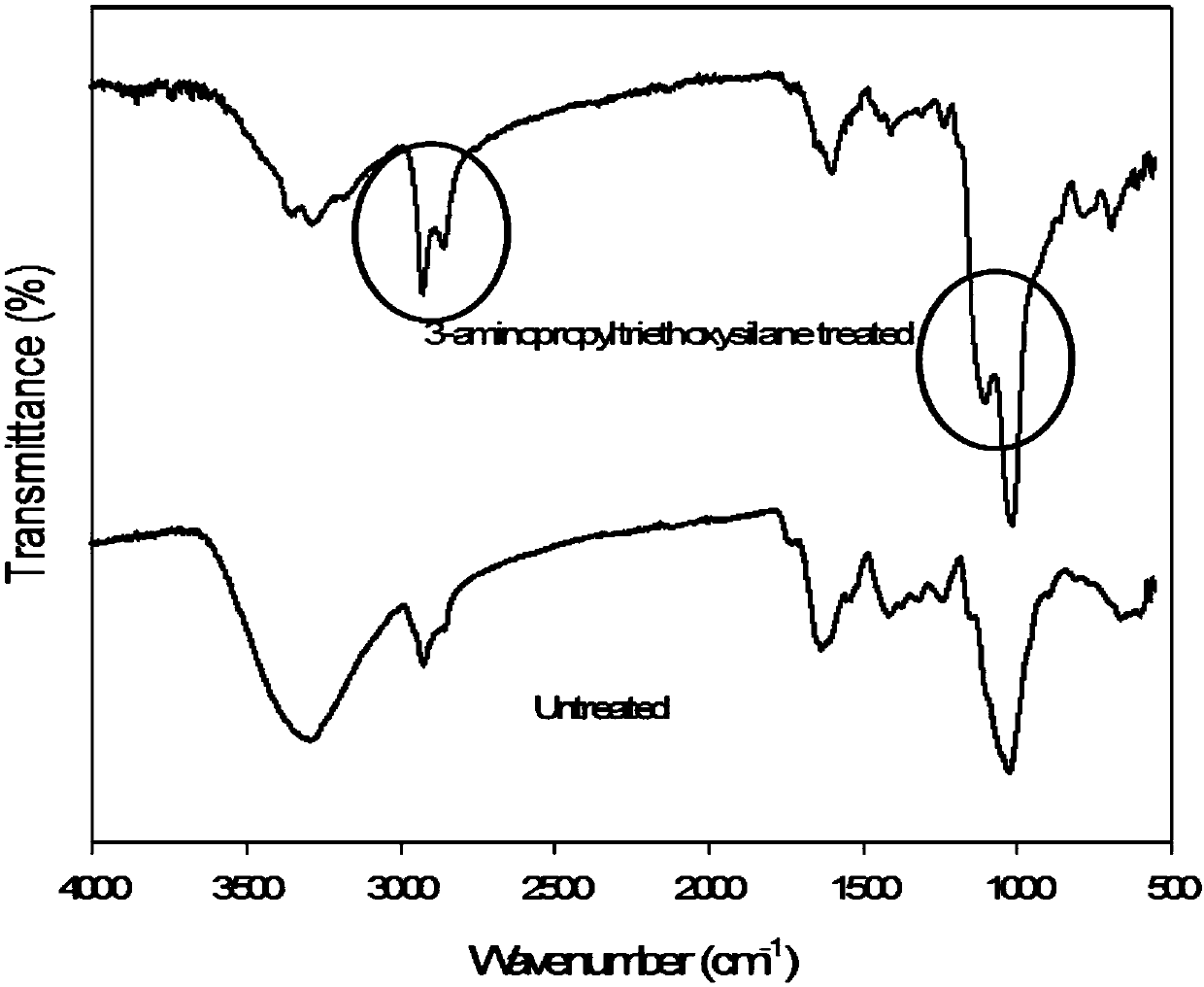

[0016] The biomass micropowder composition is made of biomass, surface modifier, coating agent, calcium oxide and titanium tetrachloride,

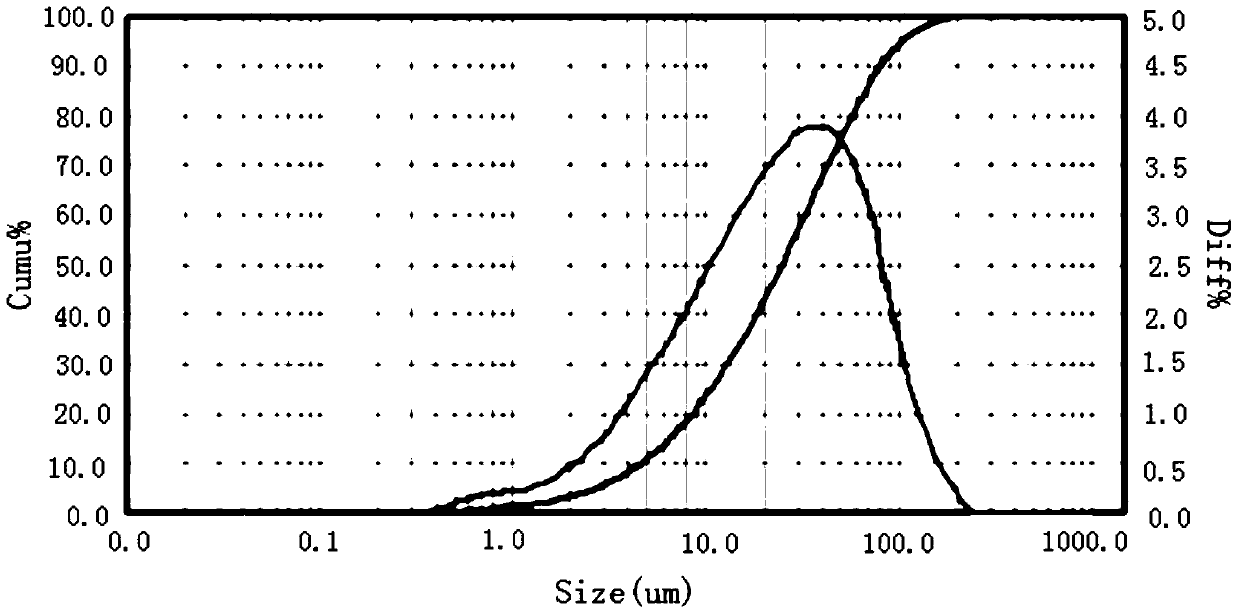

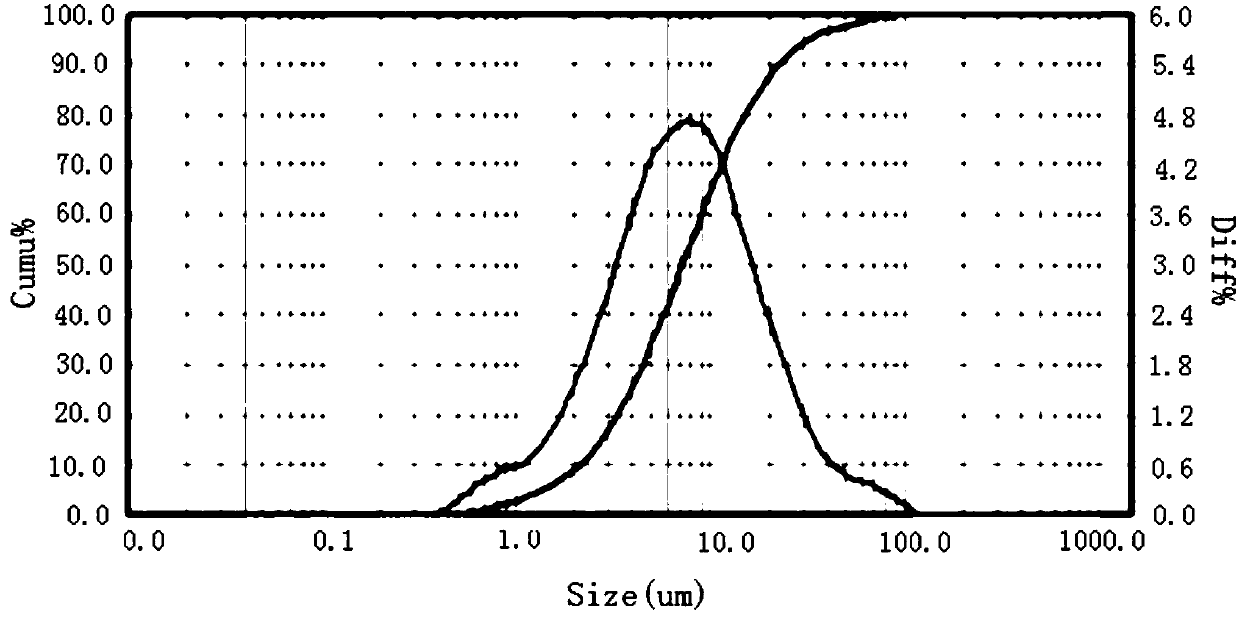

[0017] The preparation method of the biomass micropowder composition is as follows: adding calcium oxide and titanium tetrachloride to biomass coarse powder with a mass fraction of 8-10% moisture, drying, and using air flow at a temperature of 100-200°C The pulverizer is micronized, and after the micronized treatment, it is sprayed with a coating agent and a surface modifier; wherein, the amount of calcium oxide added is 10-20% of the biomass mass, and the amoun...

specific Embodiment approach 2

[0018] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: in the preparation process of the biomass micropowder composition, after calcium oxide and titanium tetrachloride are mixed with the biomass as desiccants, they are pre-heated in a constant temperature heating kettle body. Perform drying treatment, and then use a jet mill to perform micronization treatment at a temperature of 100-200°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment differs from Embodiment 1 in that in the preparation method of the biomass micropowder composition, jet mill equipment is used for pulverization during the micronization process. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com