a medical dressing

A technology of substrate and adhesive layer, applied in the field of medical articles, can solve the problem that the use effect needs to be further improved, and achieve the effect of being beneficial to wound healing and good antibacterial and moisture absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

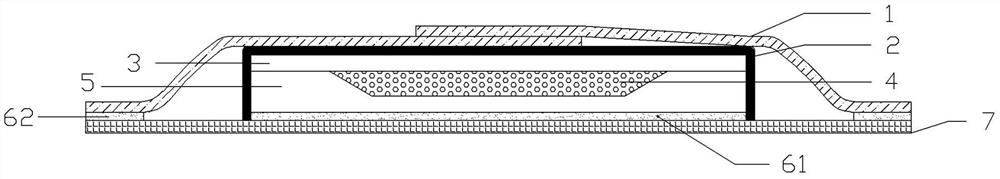

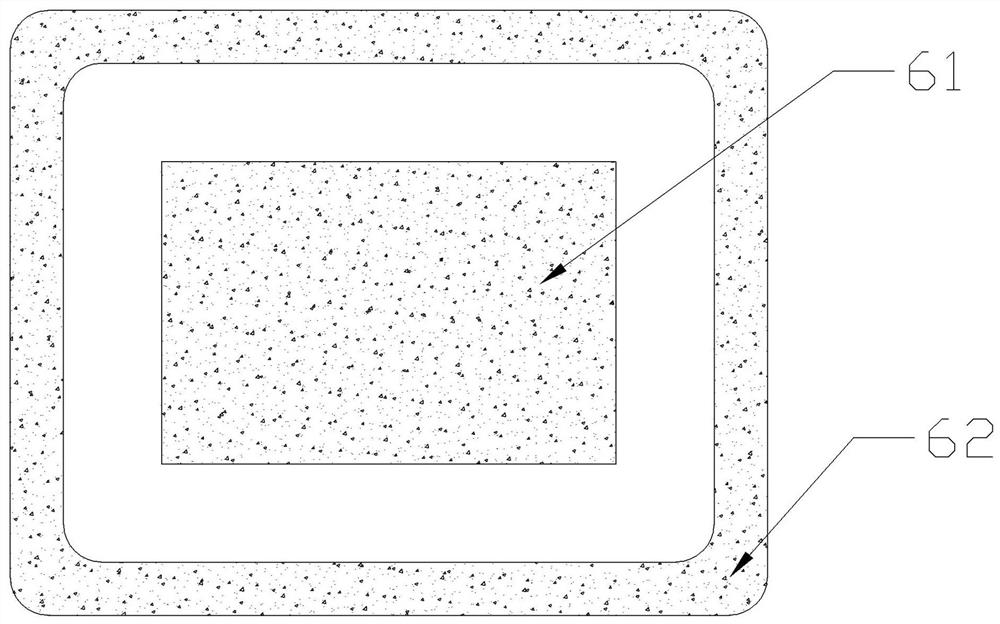

[0084] A medical dressing includes a substrate, a first nanofiber membrane, a second nanofiber membrane and a protective layer, and the first nanofiber membrane is dispersed and stacked on the surface and pores of the second nanofiber membrane.

[0085] The first nanofiber membrane is cut from a pullulan nanofiber membrane; the manufacturing process of the pullulan nanofiber membrane is electrospinning; the electrospinning of the pullulan nanofiber membrane adopts The spinning voltage is 35kv, and the spinning distance is 20cm;

[0086] The parts by weight of the raw materials for the manufacture of the pullulan nanofiber membrane are: 20 parts of pullulan, 2.5 parts of nano-chitosan particles, 0.5 parts of collagen, 0.2 parts of sodium hyaluronate, and 0.15 parts of licorice.

[0087] The invention adopts the antibacterial nano-chitosan particle loaded with pullulan polysaccharide, and the nano-chitosan particle is directly applied to the wound surface, antibacterial and abso...

Embodiment 2

[0092] A medical dressing includes a substrate, a first nanofiber membrane, a second nanofiber membrane and a protective layer, and the first nanofiber membrane is dispersed and stacked on the surface and pores of the second nanofiber membrane.

[0093] The first nanofiber membrane is cut from a pullulan nanofiber membrane; the manufacturing process of the pullulan nanofiber membrane is electrospinning; the manufacturing raw material of the pullulan nanofiber membrane is Pululan Pullulan, nano-chitosan, collagen, amino acid, sodium hyaluronate, purslane; the spinning voltage used in the electrospinning of the pullulan nanofiber membrane is 30kv, and the spinning distance is 15cm.

[0094] The ratio by weight of the raw material components of the pullulan nanofiber membrane is: 14.5 parts of pullulan, 2.6 parts of nano-chitosan particles, 0.5 part of collagen, 0.15 part of amino acid, 0.15 part of sodium hyaluronate, Purslane 0.10 parts.

[0095] The second nanofiber film is c...

Embodiment 3

[0098] A medical dressing includes a substrate, a first nanofiber membrane, a second nanofiber membrane and a protective layer, and the first nanofiber membrane is dispersed and stacked on the surface and pores of the second nanofiber membrane.

[0099] The first nanofiber membrane is cut from a pullulan nanofiber membrane; the manufacturing process of the pullulan nanofiber membrane is electrospinning; the manufacturing raw material of the pullulan nanofiber membrane is Pululan Pullulan polysaccharide, nano-chitosan, collagen, amino acid, aloe extract; the spinning voltage used in the electrospinning of the pullulan polysaccharide nanofiber membrane is 30kv, and the spinning distance is 18cm;

[0100] The raw materials for the manufacture of the pullulan nanofibrous membrane are as follows: 16.5 parts of pullulan, 3.5 parts of nano-chitosan, 0.6 part of collagen, 0.2 part of amino acid, and 0.12 part of aloe extract.

[0101] The second nanofiber film is cut from polyvinyl al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com