Sand settling device for sewage

A sand and sewage technology, which is applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of sand settling trouble, low sand settling efficiency, time-consuming and labor-intensive problems, and improve sewage purification efficiency and treatment efficiency. , the effect of improving the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

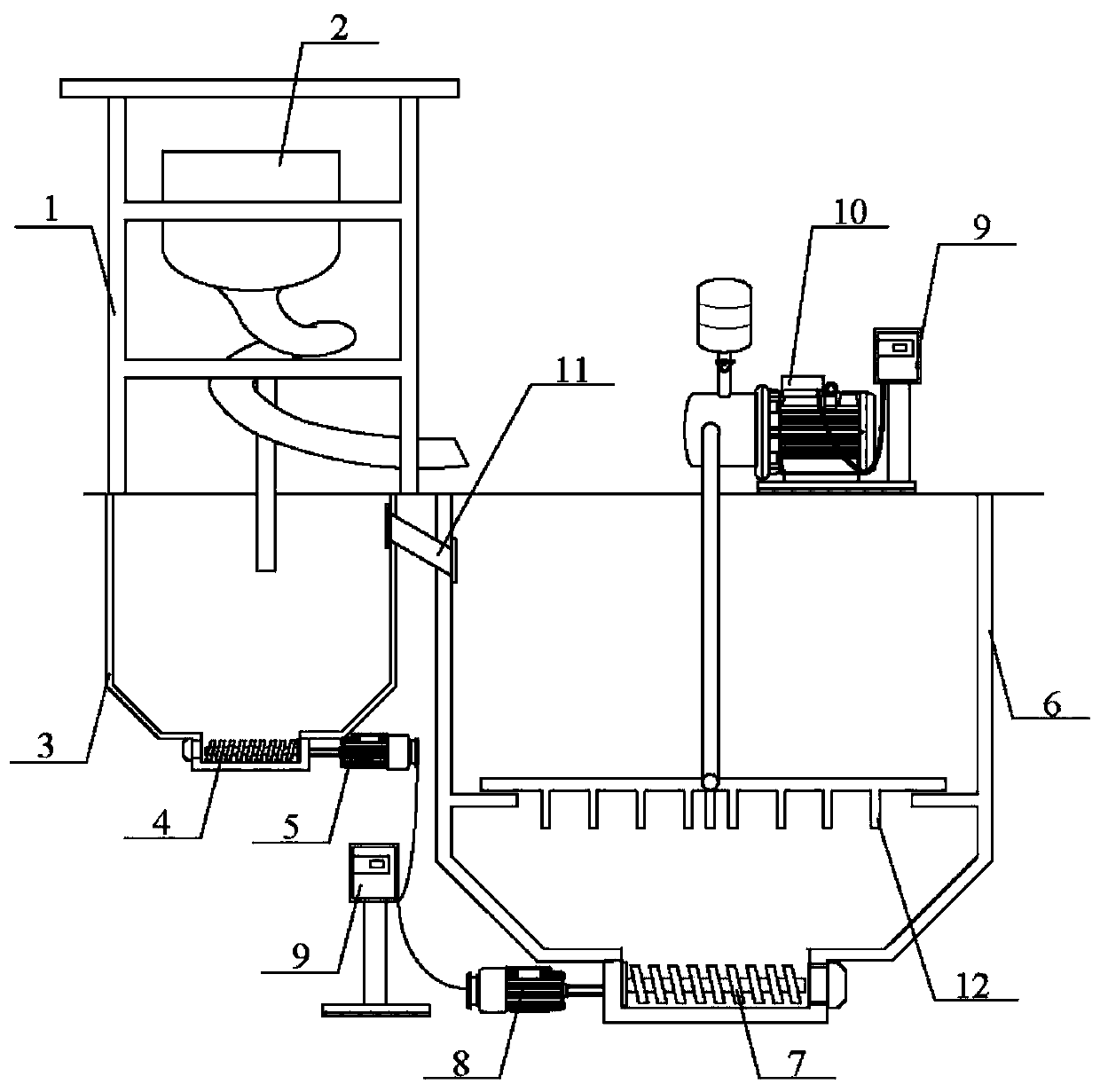

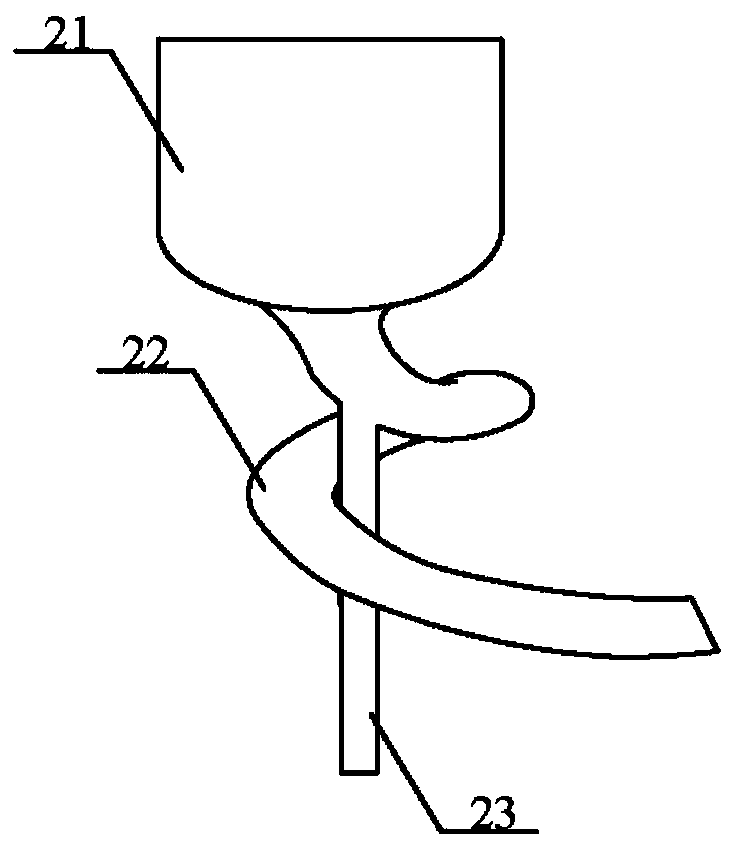

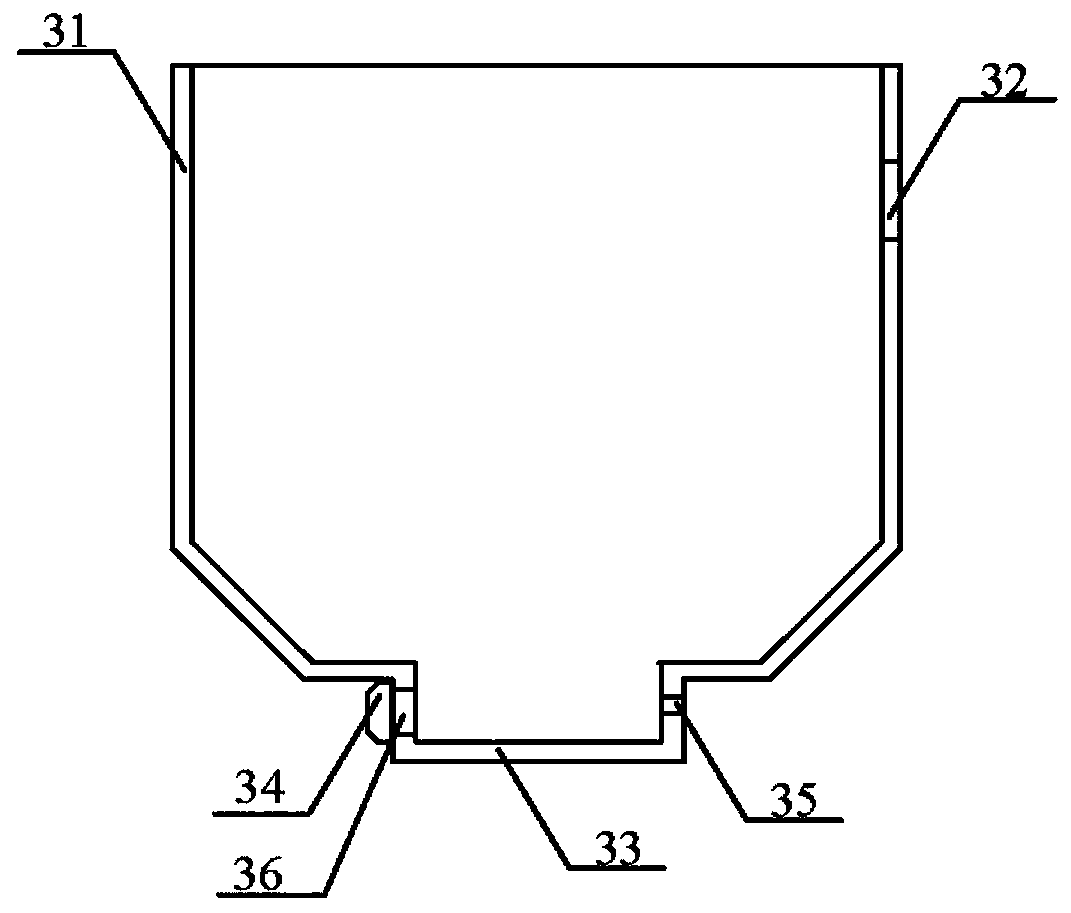

[0026] Such as Figure 1-5 As shown, the present invention provides a technical solution: a sewage grit settling device, including a fixed frame, a gravity diverter, a first grit chamber, a first dragon roller, a first motor, a second grit chamber, and a second dragon roller Roller, second motor, distribution box, sludge pump, cement pipe and water suction pipe; the fixed frame is installed on one side of the first grit chamber; the gravity flow divider is fixed inside the fixed frame by bolts, and The straight pipe extends into the first grit chamber and is lower than the water outlet, and the spiral pipe is located above the second grit chamber; the volume of the first grit chamber is 20-25 times smaller than that of the second grit chamber; the second A Jiaolong roller is installed in the first sand collection tank through the first installation hole; the first motor is connected to the first Jiaolong roller through a coupling, and connected to the distribution box through ...

Embodiment 2

[0028] A sewage grit settling device, comprising a fixed frame, a gravity diverter, a first grit chamber, a first Jiaolong roller, a first motor, a second grit chamber, a second Jiaolong roller, a second motor, a power distribution box, and a sewage mud pump, cement pipeline and water suction pipe; the fixed frame is installed on one side of the first grit chamber; the gravity flow divider is fixed inside the fixed frame by bolts, and the straight pipe extends into the first grit chamber, and Below the water outlet, the spiral pipe is located above the second grit chamber; the volume of the first grit chamber is 20-25 times smaller than that of the second grit chamber; the first Jiaolong roller is installed through the first installation hole at the second In a sand collection tank; the first motor is connected to the first Jiaolong roller through a coupling, and connected to the distribution box through a wire; the second Jiaolong roller is installed in the second sand collect...

Embodiment 3

[0031]A sewage grit settling device, comprising a fixed frame, a gravity diverter, a first grit chamber, a first Jiaolong roller, a first motor, a second grit chamber, a second Jiaolong roller, a second motor, a power distribution box, and a sewage mud pump, cement pipeline and water suction pipe; the fixed frame is installed on one side of the first grit chamber; the gravity flow divider is fixed inside the fixed frame by bolts, and the straight pipe extends into the first grit chamber, and Below the water outlet, the spiral pipe is located above the second grit chamber; the volume of the first grit chamber is 20-25 times smaller than that of the second grit chamber; the first Jiaolong roller is installed through the first installation hole at the second In a sand collection tank; the first motor is connected to the first Jiaolong roller through a coupling, and connected to the distribution box through a wire; the second Jiaolong roller is installed in the second sand collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com