A kind of catalytic oxidation catalyst and preparation method thereof, and advanced treatment method of organic matter in mdi brine

A catalytic oxidation and advanced treatment technology, which is applied in the direction of oxidized water/sewage treatment, organic compound/hydride/coordination complex catalyst, special compound water treatment, etc., can solve the problem of catalyst metal loss and achieve high degree of automation, The process is simple and the removal efficiency of organic matter is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

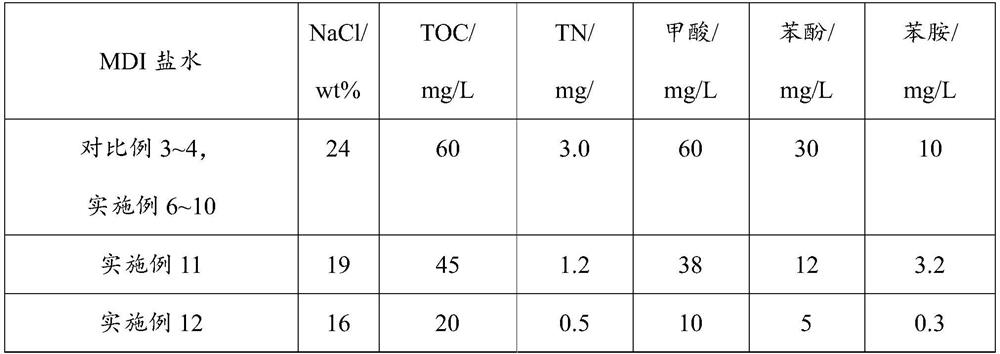

Examples

preparation example 1

[0079] Comparative Preparation Example 1 (Preparation of 1# Catalyst):

[0080] Take TiO 2 20g of the sample was placed in a dipping bottle and subjected to vacuum pretreatment. The vacuum pretreatment time was 10min, and the vacuum degree was 96.0KPa (absolute pressure). 2 10.0 mL of methanol solution containing FeCl with a concentration of 0.15 g / mL 3 13.3 mL of the methanol solution was added to the methanol aqueous solution with a methanol concentration of 10 wt % to prepare a dipping solution with a total volume of 30 mL. The above impregnation solution was then added to the 2 Vacuum impregnation bottle of carrier and mix well, TiO 2 The carrier was immersed in an excess volume of immersion solution. After immersion for 30 minutes, the immersed product was taken out and dried in an oven at 90°C for 2 hours, and then calcined at 300°C for 4 hours in a muffle furnace to obtain 1# catalyst.

[0081] In the obtained 1# catalyst, the carrier TiO 2 The weight is 1 meter, N...

preparation Embodiment 1

[0085] Preparation Example 1 (Preparation of 3# Catalyst):

[0086] Take TiO 2 20g of the sample was placed in a dipping bottle and subjected to vacuum pretreatment. The vacuum pretreatment time was 40min, and the vacuum degree was 97.0KPa (absolute pressure); at the same time, a concentration of 0.20g / mL containing EG-CholineCl-NiCl 2 10.0 mL of methanol solution containing EG-CholineCl-FeCl with a concentration of 0.30 g / mL 3 6.65 mL of the methanol solution was added to the methanol aqueous solution with a methanol concentration of 10 wt % to prepare a dipping solution with a total volume of 30 mL. The above impregnation solution was then added to the 2 Vacuum impregnation bottle of carrier and mix well, TiO 2 The carrier was immersed in an excess volume of immersion solution. After immersion for 60 minutes, the immersed product was taken out and dried in an oven at 120 °C for 2 hours, and then calcined in a muffle furnace at 300 °C for 4 hours to obtain 3# catalyst.

...

preparation Embodiment 2

[0088] Preparation Example 2 (Preparation of 4# Catalyst):

[0089] Take TiO 2 20g of the sample was placed in a dipping bottle and subjected to vacuum pretreatment. The vacuum pretreatment time was 10min, and the vacuum degree was 96.0KPa (absolute pressure); at the same time, a concentration of 0.20g / mL containing EG-CholineCl-NiCl 2 1.0mL of methanol solution containing EG-CholineCl-FeCl with a concentration of 0.15g / mL 3 1.4 mL of the methanol solution was added to the methanol aqueous solution with a methanol concentration of 10 wt% to prepare a dipping solution with a total volume of 20 mL. The above impregnation solution was then added to the 2 Vacuum impregnation bottle of carrier and mix well, TiO 2 The carrier was immersed in an excess volume of immersion solution. After immersion for 240 minutes, the immersed product was taken out and dried in an oven at 150°C for 5h, and then calcined at 400°C for 5h in a muffle furnace to obtain 4# catalyst.

[0090] In the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com