Catalytic oxidation catalyst, preparation method thereof, and advanced treatment method of organic matters in MDI brine

A catalytic oxidation and advanced treatment technology, applied in the fields of oxidized water/sewage treatment, organic compound/hydride/coordination complex catalyst, special compound water treatment, etc. High load efficiency and load stability, the effect of improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

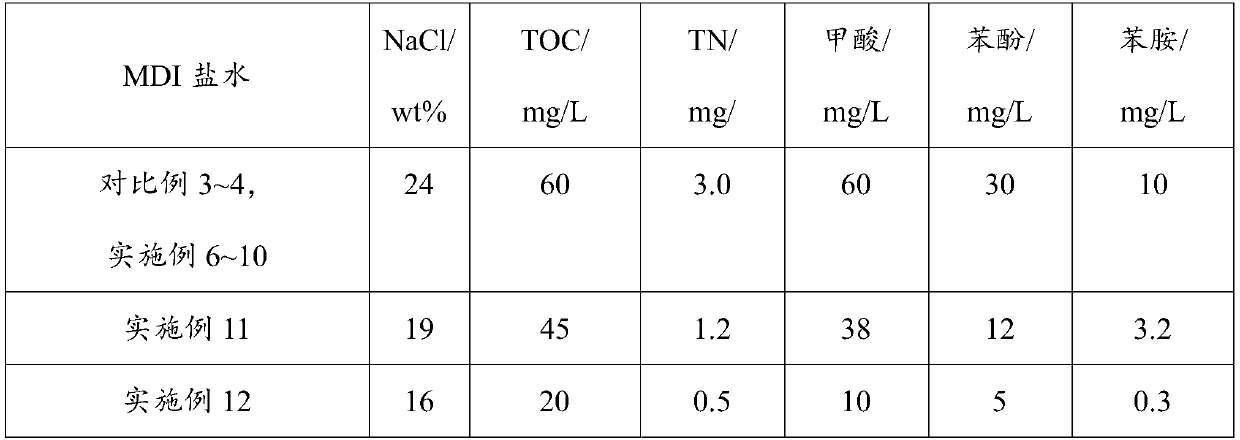

Examples

preparation Embodiment 1

[0085] Preparation Example 1 (preparation of 3# catalyst):

[0086] TiO 2 Sample 20g is placed in the impregnating bottle, carries out vacuum pretreatment, and the time of vacuum pretreatment is 40min, and vacuum degree is 97.0KPa (absolute pressure); 2 10.0mL of methanol solution containing EG-CholineCl-FeCl with a concentration of 0.30g / mL 3 Add 6.65mL of methanol solution of 10wt% methanol to prepare an impregnation solution with a total volume of 30mL. Then the above impregnation solution was added to the TiO 2 Vacuum impregnated bottle of carrier and mix well, TiO 2 The carrier was impregnated in an excess volume of impregnating solution. After impregnating for 60 minutes, the impregnated product was taken out and dried in an oven at 120°C for 2h, and then calcined in a muffle furnace at 300°C for 4h to obtain 3# catalyst.

[0087] In the obtained 3# catalyst, with carrier TiO 2 The weight is 1 meter, EG-CholineCl-NiCl 2 The content percentage is 10.0wt%, EG-Choline...

preparation Embodiment 2

[0088] Preparation Example 2 (preparation of 4# catalyst):

[0089] TiO 2 Sample 20g is placed in the impregnating bottle, carries out vacuum pretreatment, and the time of vacuum pretreatment is 10min, and vacuum degree is 96.0KPa (absolute pressure); 2 1.0mL methanol solution containing EG-CholineCl-FeCl with a concentration of 0.15g / mL 3 Add 1.4mL of the methanol solution of 1.4mL to the methanol aqueous solution with a methanol concentration of 10wt%, to prepare an impregnation solution with a total volume of 20mL. Then the above impregnation solution was added to the TiO 2 Vacuum impregnated bottle of carrier and mix well, TiO 2 The carrier was impregnated in an excess volume of impregnating solution. After impregnating for 240min, the impregnated product was taken out and dried in an oven at 150°C for 5h, and then calcined in a muffle furnace at 400°C for 5h to obtain 4# catalyst.

[0090] In the resulting 4# catalyst, with carrier TiO 2 The weight is 1 meter, EG-Cho...

preparation Embodiment 3

[0091] Preparation Example 3 (preparation of 5# catalyst):

[0092] TiO 2 Sample 20g is placed in the impregnating bottle, carries out vacuum pretreatment, and the time of vacuum pretreatment is 30min, and vacuum degree is 96.0KPa (absolute pressure); 2 4.0mL methanol solution containing EG-CholineCl-FeCl with a concentration of 0.15g / mL 3 Add 8.0mL of methanol solution of 10wt% methanol to prepare an impregnating solution with a total volume of 20mL. Then the above impregnation solution was added to the TiO 2 Vacuum impregnated bottle of carrier and mix well, TiO 2 The carrier was impregnated in an excess volume of impregnating solution. After impregnating for 60 minutes, the impregnated product was taken out and dried in an oven at 90°C for 3h, and then calcined in a muffle furnace at 350°C for 4h to obtain 5# catalyst.

[0093] In the resulting 5# catalyst, the carrier TiO 2 The weight is 1 meter, EG-CholineCl-NiCl 2 The content percentage is 4.0wt%, EG-CholineCl-FeCl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com