Comprehensive disposal method of metronidazole wastewater

A comprehensive treatment and metronidazole technology, applied in the field of high-salt and high-COD chemical wastewater treatment, can solve the problems that restrict the healthy development of metronidazole raw materials, high concentration of organic pollutants, high salinity of metronidazole wastewater, and achieve recovery costs Low cost, high recovery efficiency, and cost-saving treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

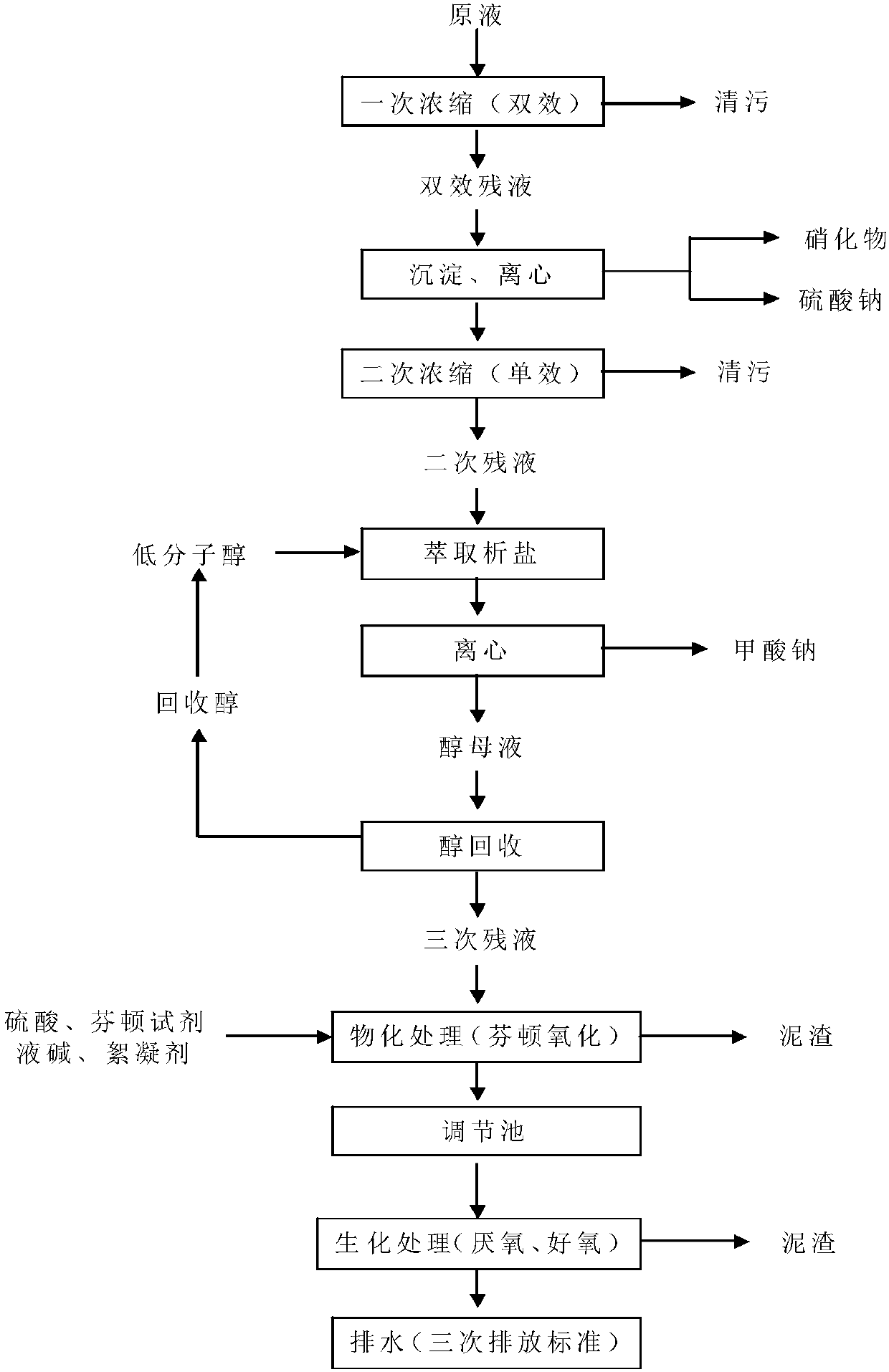

[0049] The present embodiment provides a kind of comprehensive treatment method of metronidazole waste water, such as figure 1 As shown, the details are as follows:

[0050] Add the waste water stock solution into a container (such as a flask), stir, and concentrate under reduced pressure (90°C, -0.09MPa) until the raffinate volume is 52% of the waste stock solution, collect fractions, and cool the raffinate (primary raffinate) to Centrifuge at 35°C to obtain a white granular solid. Continue to concentrate the filtrate under reduced pressure (90°C, -0.09MPa) to a water content of 5%. Water and ethanol were stirred for 60 minutes, cooled to 25°C, filtered to obtain a yellowish granular solid, the filtrate was distilled at atmospheric pressure, and ethanol was recovered. When the concentrated solution was heated to 110°C, no fractions flowed out, and the distillation was completed to obtain a dark red raffinate ( Three times of raffinate), adding water of 1 times the quality of...

Embodiment 2

[0053] Add the waste water stock solution into the flask, stir, and concentrate under reduced pressure (90°C, -0.09MPa) until the residual liquid volume is 46.8% of the original water liquid, collect fractions, cool the residual liquid (primary residual liquid) to 35°C, and centrifugally filter. Obtain a white granular solid, continue to concentrate the filtrate under reduced pressure (90°C, -0.09MPa) to a water content of 8%, and obtain a secondary raffinate, add anhydrous methanol twice the mass of the secondary raffinate while hot, and stir for 60 minutes , cooled to 25°C, filtered to obtain a yellowish granular solid, the filtrate was distilled at atmospheric pressure, methanol was recovered, no fractions flowed out when the concentrated solution was heated to 90°C, and the distillation was completed to obtain a dark red raffinate (three raffinate), which was sent to Add three times the amount of residual liquid to 1 times the mass of water for dilution.

[0054] Take the ...

Embodiment 3

[0056] Add the waste water stock solution into the flask, stir, and concentrate under vacuum distillation (90°C, -0.09MPa) until the volume of the residual liquid is 56% of the original water liquid, collect fractions, cool the residual liquid (primary residual liquid) to 35°C, and centrifugally filter. A white granular solid was obtained, and the filtrate continued to be concentrated under reduced pressure (90°C, -0.09MPa) until the water content was 11%, and the secondary raffinate was obtained, and anhydrous methanol with 1.5 times the mass of the secondary raffinate was added while it was hot, and stirred for 60 minutes , cooled to 25°C, and centrifuged to obtain a yellowish granular solid. The filtrate was distilled at atmospheric pressure, and methanol was recovered. When the concentrated solution was heated to 90°C, no fractions flowed out, and the distillation was completed to obtain a dark red raffinate (three raffinate), Add water of 1 times the mass of the three resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com