Selection method for recovering needle-like wollastonite from mixed ores

A needle-shaped wollastonite and mixed ore technology, applied in the direction of solid separation, etc., can solve the problems of low enrichment ratio, coarse sorting particle size, and inability to recover Tc-type wollastonite, so as to achieve the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

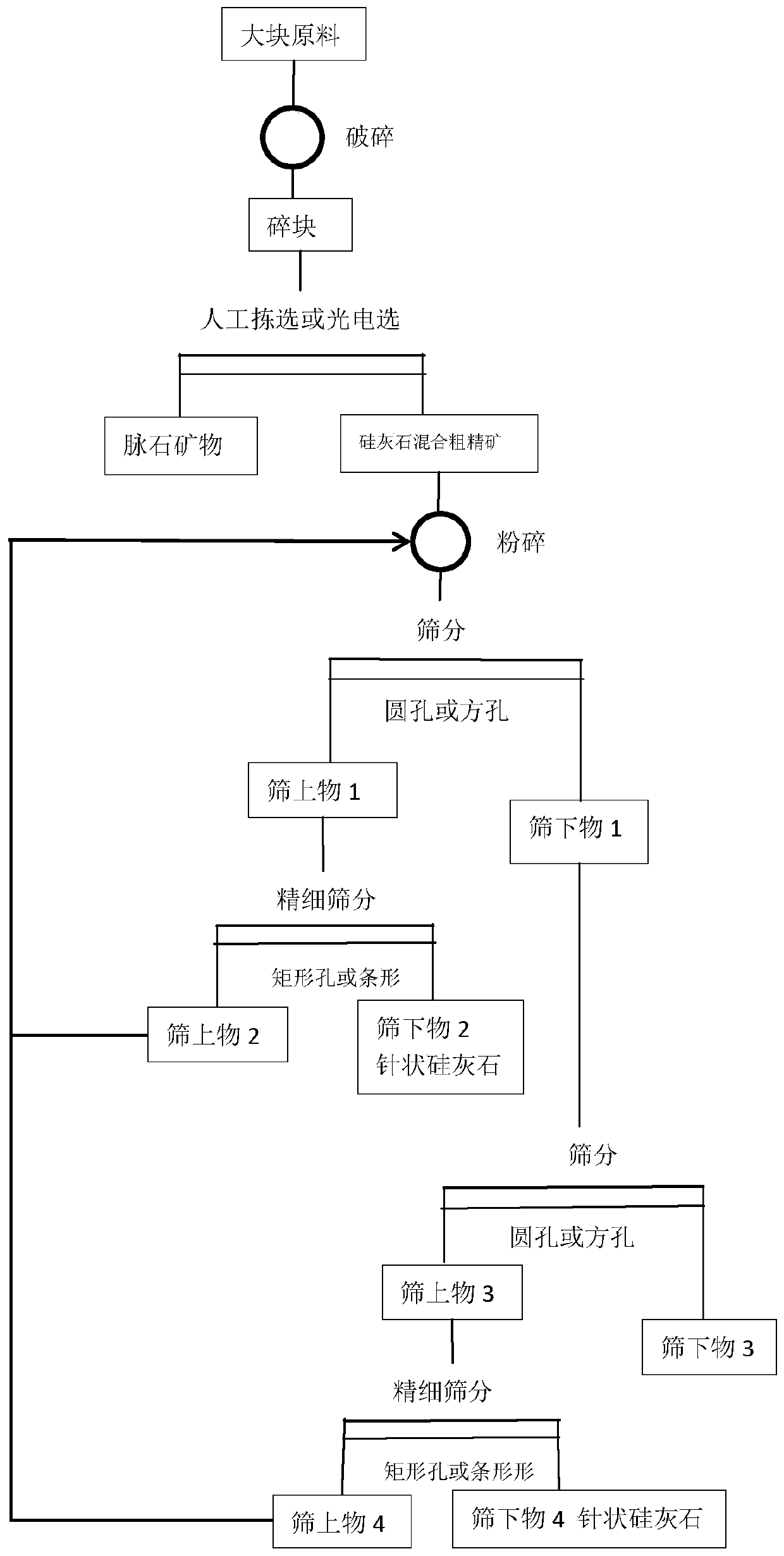

Image

Examples

Embodiment 1

[0030] A wollastonite mixed ore 1, the minerals in the original ore include wollastonite, calcite, quartz, diopside, fushanite, etc., among which wollastonite is mainly Tc type wollastonite and ZM parawollastonite, false wollastonite A small amount of stone. The largest particle size of the raw ore is less than 400mm, and about 80% of the ore blocks have a particle size of 250-450mm, and the water content is about 3.5%.

[0031] The beneficiation method of reclaiming acicular wollastonite from this wollastonite mixed ore 1 comprises the following steps:

[0032] (1) The raw ore is put into an impact crusher 1, and the maximum particle size of the fragments after crushing is about 100 mm. Most of the gangues such as calcite and quartz are removed by manual selection to obtain wollastonite mixed coarse concentrate;

[0033] (2) Put wollastonite mixed coarse concentrate into impact crusher 2 and be crushed into scrap, the maximum particle size of scrap is 20mm;

[0034] (3) The...

Embodiment 2

[0041] A wollastonite mixed ore 2, the minerals in the original ore include wollastonite, quartz, calcite and other minerals in a small amount, of which wollastonite is mainly Tc type wollastonite and ZM parawollastonite, a small amount of false wollastonite, needle-shaped The mineral weight of wollastonite accounts for about 30% of the original ore weight. The largest particle size of raw ore is less than 350mm, and about 90% of the ore block particle size is 200-350mm, and the water content is about 3.0%.

[0042] The beneficiation method of reclaiming acicular wollastonite from this wollastonite mixed ore 2 may further comprise the steps:

[0043] (1) The raw ore is put into a jaw crusher, and the maximum particle size of the crushed small pieces is about 125mm. Most of the gangues such as quartz are removed by manual selection to obtain wollastonite mixed coarse concentrate;

[0044] (2) put wollastonite mixed coarse concentrate into impact crusher and be crushed into scr...

Embodiment 3

[0052] A wollastonite mixed ore 3, the minerals in the original ore include wollastonite, calcite, and a small amount of other gangue minerals, of which wollastonite includes Tc type wollastonite and ZM parawollastonite, the largest particle size of the original ore is less than 300mm, and About 90% of the ore blocks have a particle size of 150-300mm and a water content of about 2.0%.

[0053] The beneficiation method of reclaiming acicular wollastonite from this wollastonite mixed ore 3 comprises the following steps:

[0054] (1) The raw ore is put into an impact crusher 1, and the maximum particle size of the fragments after crushing is about 75mm, and most of the gangues such as quartz are removed by manual selection to obtain wollastonite mixed coarse concentrate;

[0055] (2) Put wollastonite mixed coarse concentrate into impact crusher 2 and be pulverized into scrap, the maximum particle diameter of scrap is 5mm;

[0056] (3) The crushed material is put into a circular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com