A kind of vertical graphene-polymer composite material and preparation method thereof

A high molecular polymer and composite material technology, applied in the field of vertical graphene-high molecular polymer composite materials and its preparation, can solve the problems of destroying vertical morphology and microstructure, destroying structure, and easily contaminating active substances, etc., to achieve The effect of protecting the unique structure and huge surface area, wide application scenarios, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

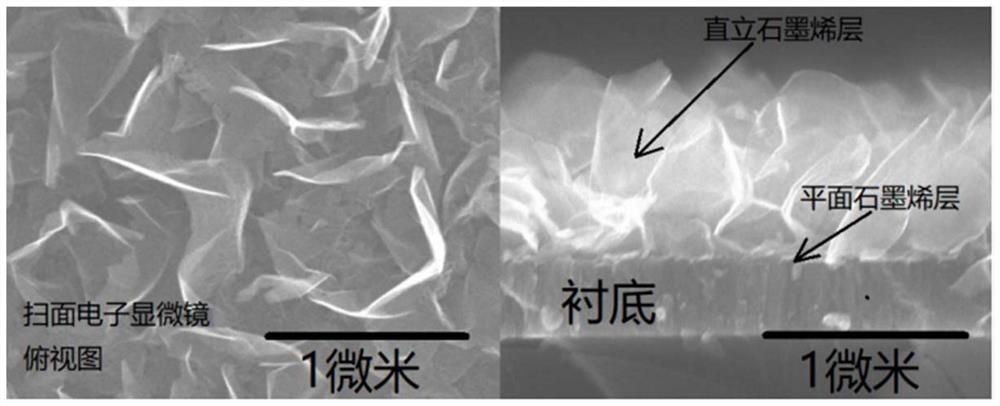

[0044] A vertical graphene-Nafion composite material, including a highly conductive carbon paper substrate, vertical graphene and polymer Nafion. The vertical graphene grows on the surface of the highly conductive carbon paper substrate, and the polymer Nafion is evenly loaded on the surface and edge of the vertical graphene.

[0045] Vertical graphene includes two parts: a planar graphene layer close to the substrate and a vertical graphene layer embedded in a polymer.

[0046] A kind of preparation method of vertical graphene-Nafion composite material, comprises the steps at least:

[0047] In the first step, put the high-conductivity carbon paper into the vacuum chamber of the plasma chemical vapor deposition device, feed the reducing gas hydrogen and argon at 1:1, and maintain the low pressure state in the device through flow adjustment, so that the vacuum degree is stable at 15Pa, conduct plasma etching reaction on highly conductive carbon paper, the reaction time is 10m...

Embodiment 2

[0055] Different from Example 1 is the preparation method of vertical graphene / high molecular polymer composite material, the method at least comprises the following steps:

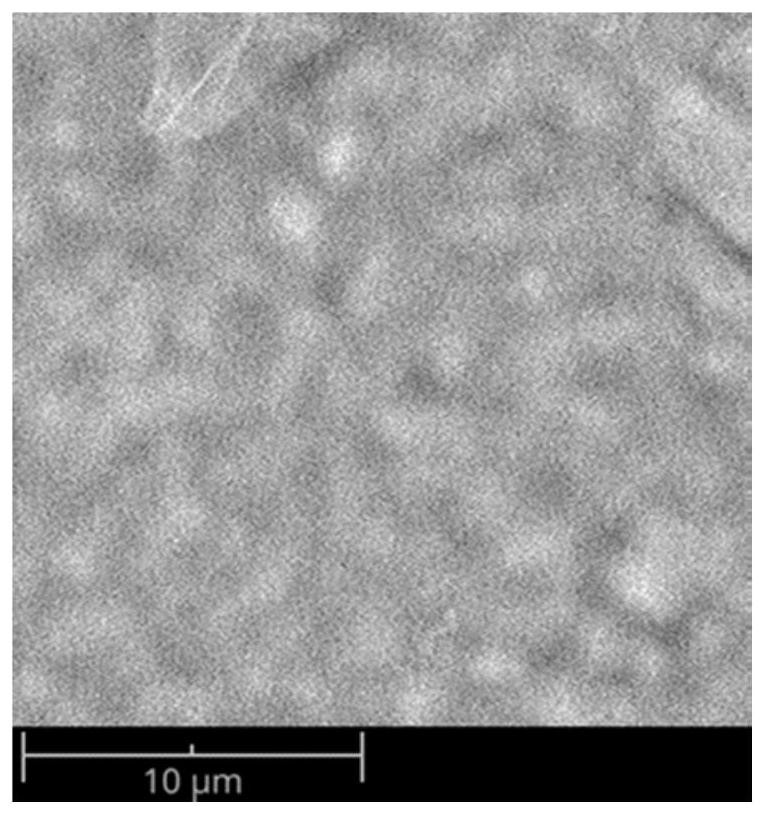

[0056] In the first step, the polished silicon wafer is placed in the vacuum chamber of the plasma chemical vapor deposition device, and the reducing gas hydrogen and argon are introduced at a ratio of 1:1, and the low pressure state in the device is maintained by flow adjustment, so that the vacuum degree is stable at 15Pa , carry out plasma etching reaction on the substrate, the reaction time is 10min, and the power density of the plasma equipment is 10 watts per square centimeter;

[0057] In the second step, argon gas is introduced after the etching reaction is completed, and heated to 700 °C at a heating rate of 20 °C / min. After heating, hydrogen and methane are injected at a ratio of 1:1, and the low pressure state in the device is maintained through flow adjustment to maintain vacuum The degree is ...

Embodiment 3

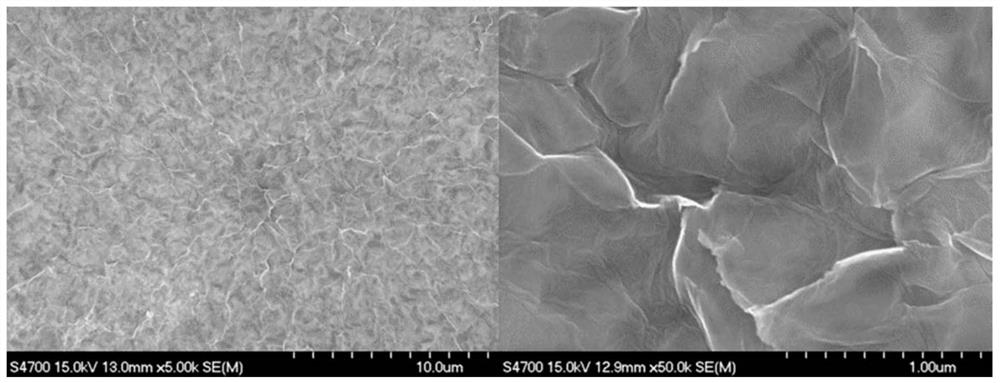

[0065] Different from Example 1 is the preparation method of vertical graphene / high molecular polymer composite material, the method at least comprises the following steps:

[0066] In the first step, put the high-conductivity carbon paper into the vacuum chamber of the plasma chemical vapor deposition device, feed the reducing gas hydrogen and argon at 1:1, and maintain the low pressure state in the device through flow adjustment, so that the vacuum degree is stable at 15Pa, conduct plasma etching reaction on highly conductive carbon paper, the reaction time is 10min, and the power density of plasma equipment is 10 watts per square centimeter;

[0067] In the second step, argon gas is introduced after the etching reaction is completed, and heated to 700 °C at a heating rate of 20 °C / min. After heating, hydrogen and methane are injected at a ratio of 1:1, and the low pressure state in the device is maintained through flow adjustment to maintain vacuum The degree is 15Pa;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com