Material positioning moving rod detection mechanism

A technology of movable rods and materials, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as large shaking, poor detection accuracy, and potential safety hazards, so as to reduce the number of inspections, increase the contact area, and improve The effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

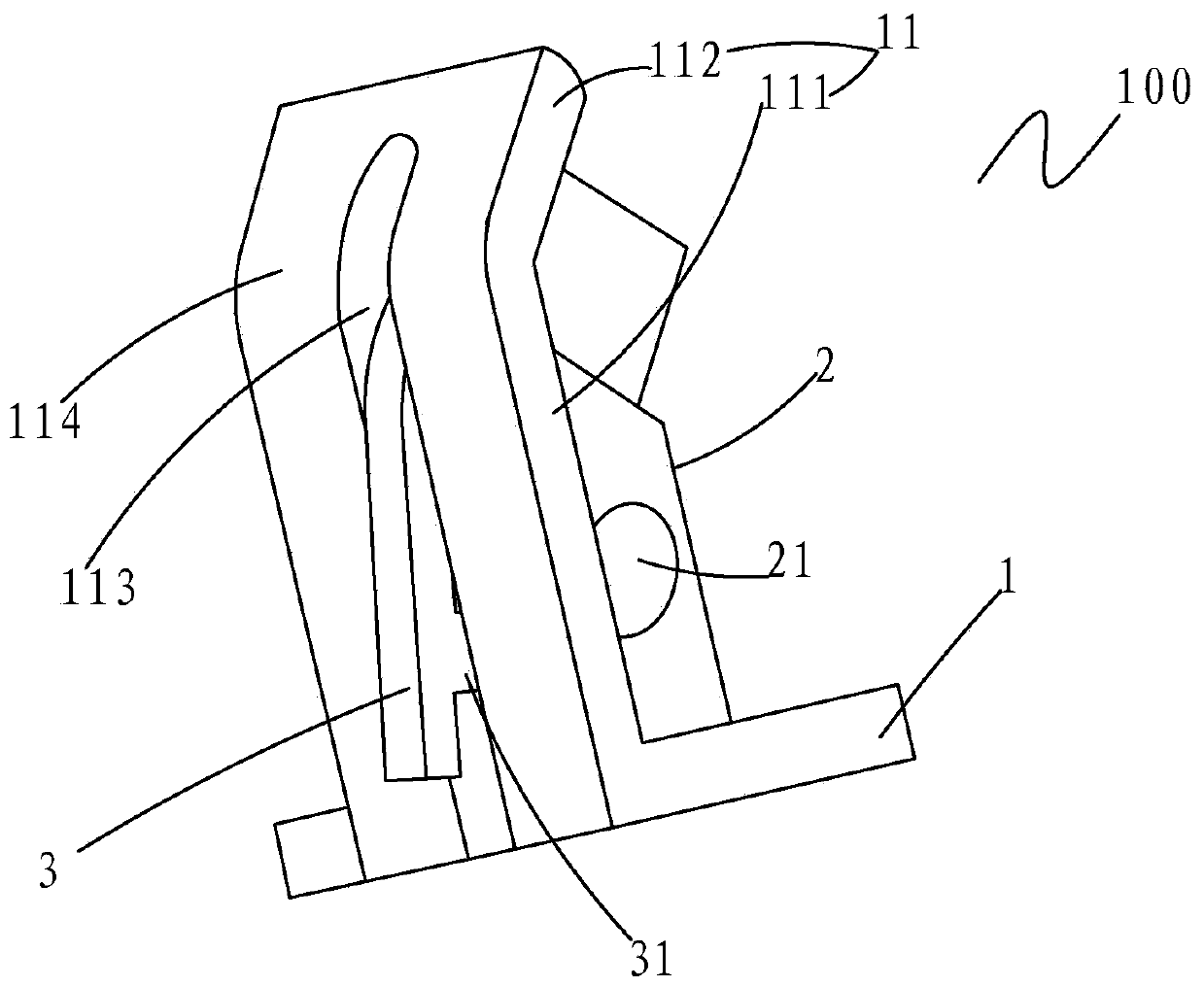

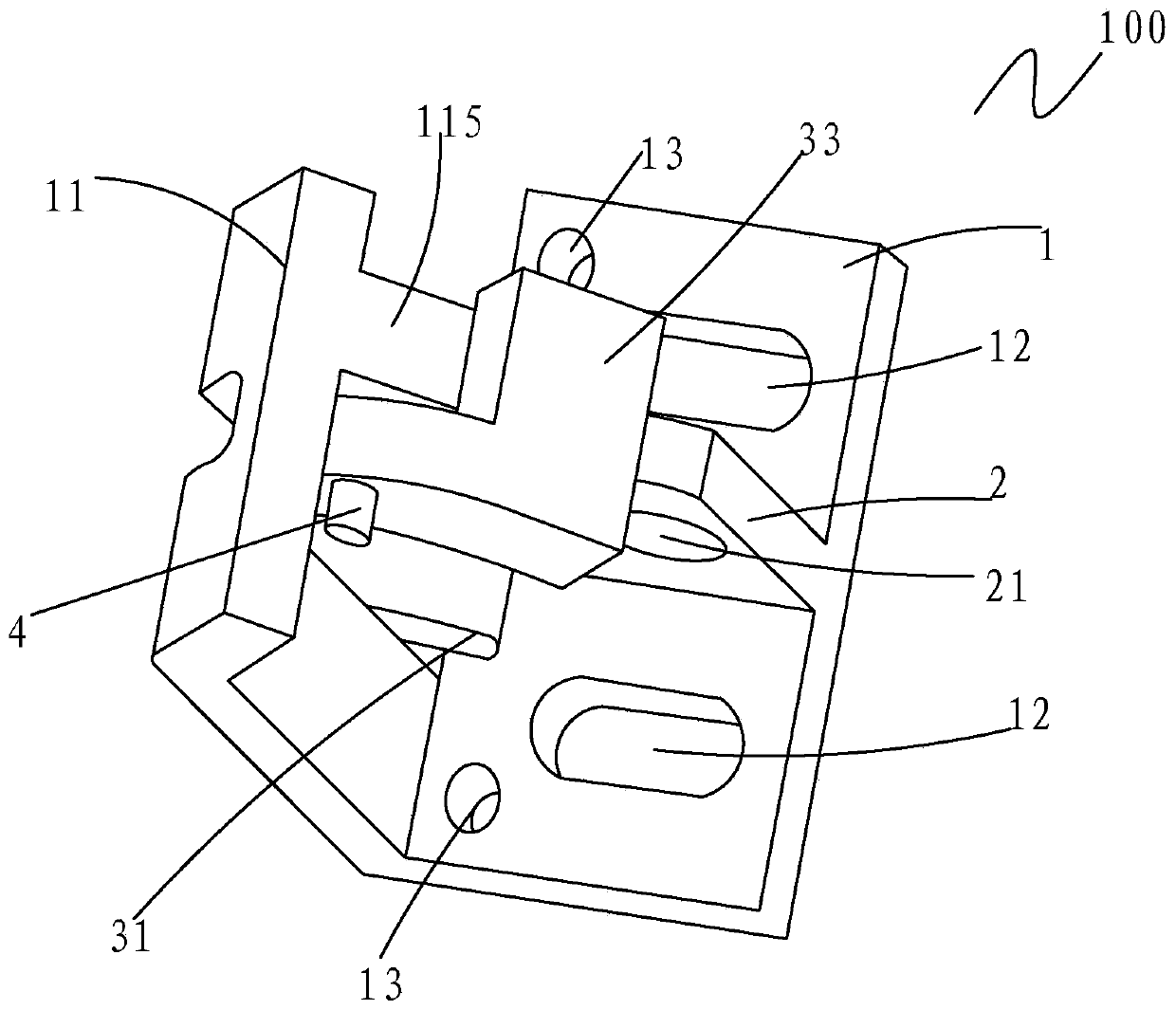

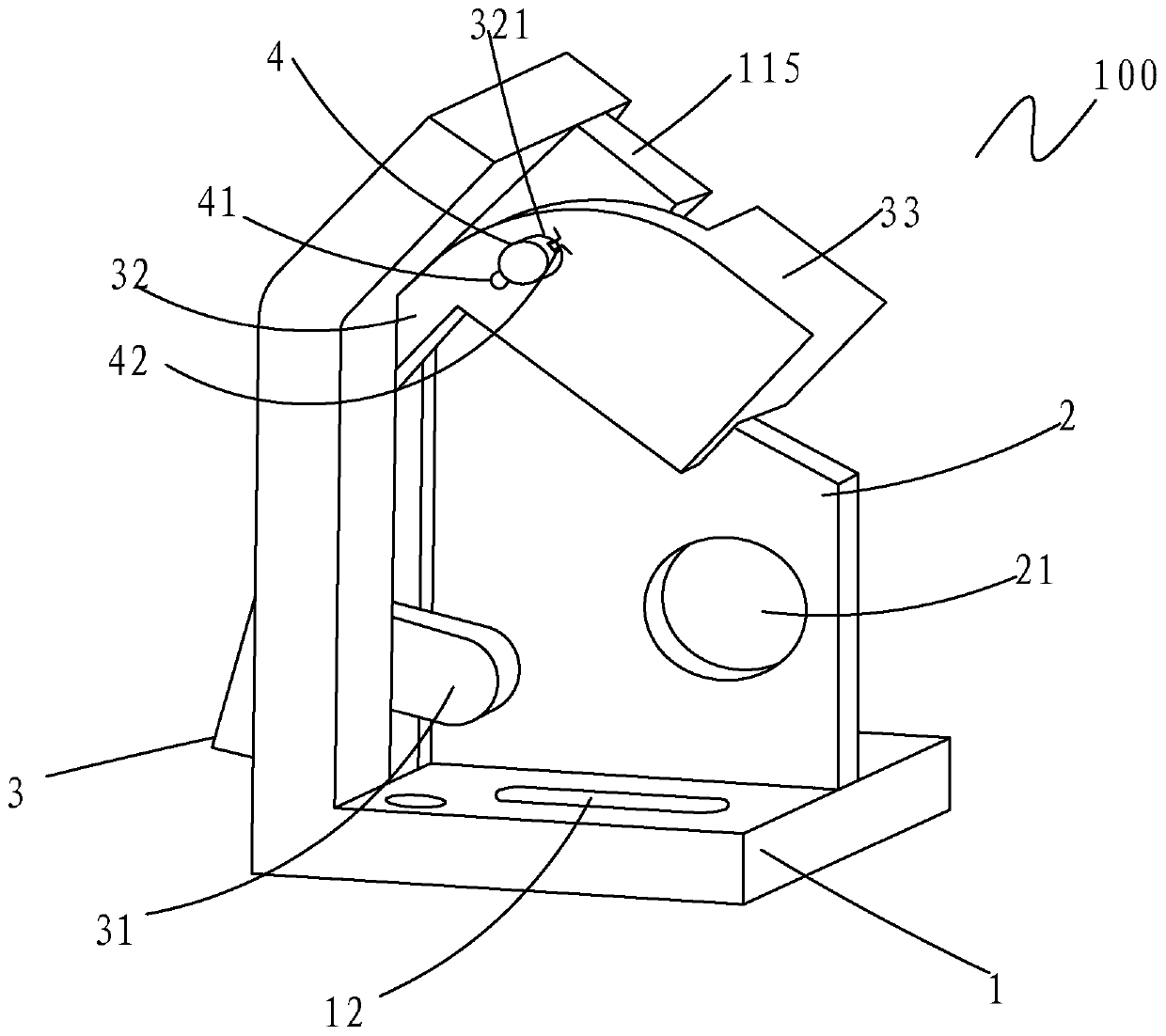

[0028] see Figures 1 to 4 shown.

[0029] The present invention provides a material positioning movable rod detection mechanism 100, including

[0030] The base 1, the left end of the base 1 is provided with a movable rod mount 11; the movable rod mount 11 includes a vertical plate 111 and a guide plate 112; the guide plate 112 is connected to the top of the vertical plate 111, And the guide plate 112 is inclined to the upper right, so that the left side 114 of the guide plate and the vertical plate 111 serves as a guiding sensing surface, and has a guiding function, and the material 5 slides in from the left side of the guide plate 111. In the mold, compared with the existing only one movable rod, the present invention increases the contact area between the material and the movable rod mounting seat 11, so that the material 5 slides in more smoothly, reduces the shaking amount, and improves the detection accuracy; The movable rod mounting seat 11 is provided with a through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com