Walking mechanism of steel casting transporting vehicle

A technology of walking mechanism and transport vehicle, which is applied in the direction of transportation and packaging, motion deposition, vehicle parts, etc. It can solve the problems of easy damage of springs, etc., and achieve the effect of improving pressure bearing capacity, strong supporting capacity, and high compressive resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

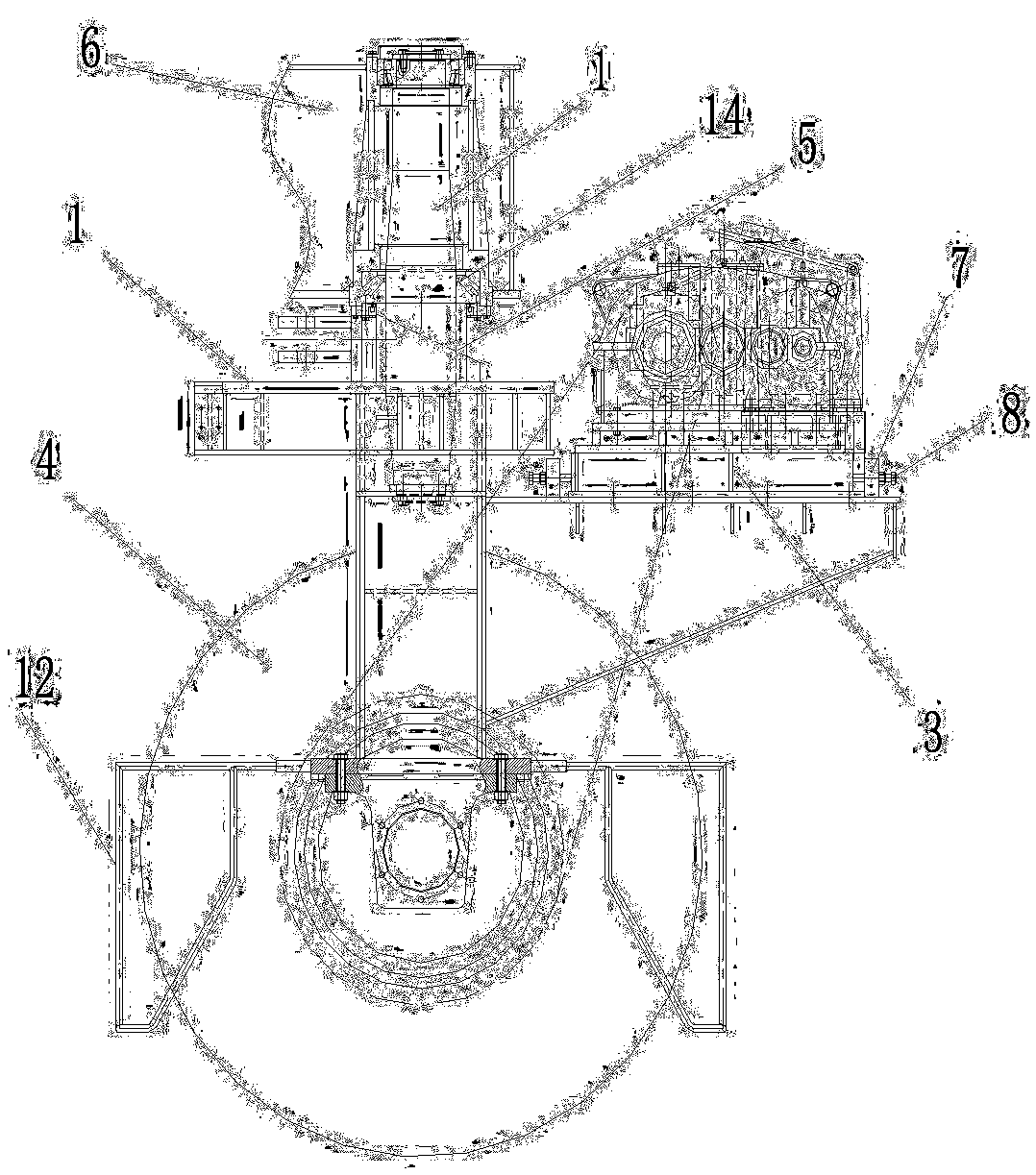

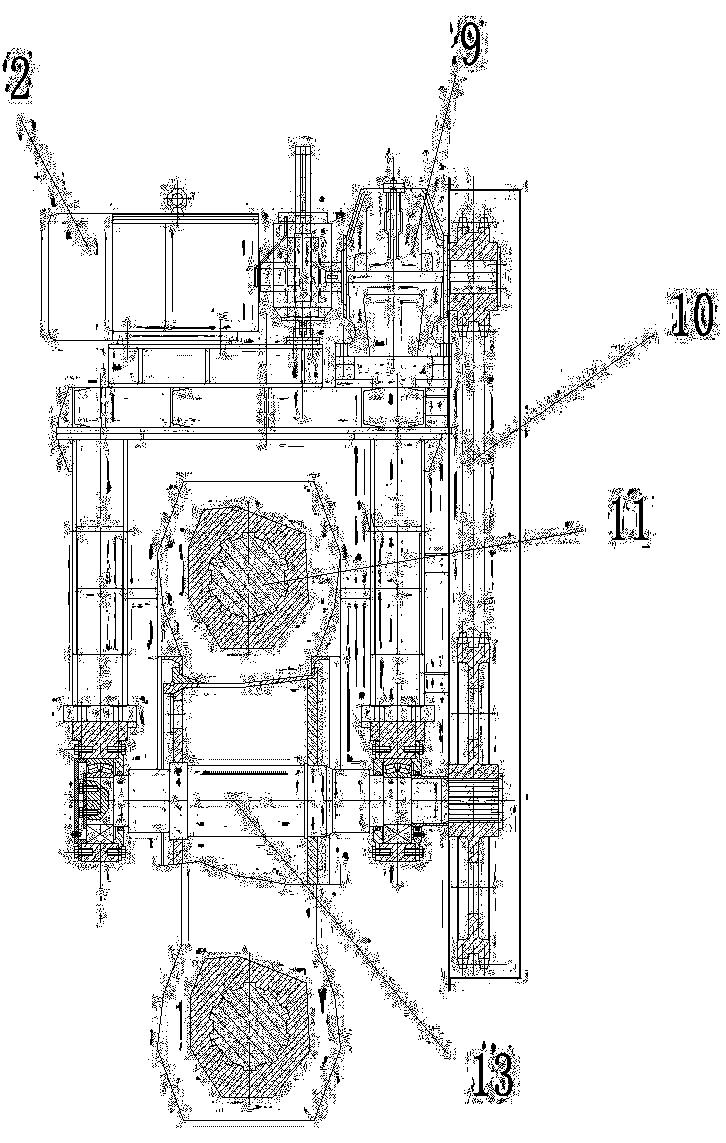

[0010] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as Figure 1-Figure 2 As shown, a walking mechanism of a steel casting transport vehicle includes a vehicle frame 1, a motor 2, a movable base 3 and wheels 4. The vehicle frame is provided with a limit hole 5, and the column is inserted into the limit hole, and the bottom of the column passes through the Bolts are fixedly connected with the vehicle frame, the middle part of the upright is closely matched with the limit hole, the upper part of the upright passes through the chassis 6 and is connected through the bearing 14; the upright can be disassembled by setting the limit hole, the upright is connected with the chassis through two bearings, and the bearing Thrust bearings are adopted, which can not only rotate, but also support the upper chassis.

[0011] In order to be able to adjust the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com