A kind of preparation method of pc-abs alloy material

A technology of PC-ABS and alloy materials, which is applied in the field of preparation of PC-ABS alloy materials, can solve the problems of influence on the mechanical properties of alloy materials, different polarities, poor melting effect, etc., to improve anti-aging performance and reduce gloss degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a kind of preparation method of PC-ABS alloy material, comprises the following steps:

[0040] (1) Prepare raw materials by weight:

[0041] 65~75 parts of PC resin; 25~35 parts of ABS resin

[0042] 1-2 parts of compatibilizer; 0.1-1 part of lubricant;

[0043] 3 to 5 parts of sulfonated SBS resin; the degree of sulfonation is 0.3 mmol / g to 0.6 mmol / g;

[0044] (2) Dry the PC resin and ABS resin, then add the rest of the raw materials and use a blender to mix evenly, use a screw extruder to heat and extrude, cool and cut into pellets after extrusion to obtain alloy material particles.

[0045] The compatibilizer and lubricant of the present invention can adopt the compatibilizer and lubricant commonly used in PC / ABS in the prior art, and the present invention is verified through many tests, and it is found that the compatibilizer can have an impact on the mechanical properties of the material, However, it does not interact with the sulfonated SB...

Embodiment 1

[0048] The preparation method of PC / ABS alloy material disclosed by the invention

[0049] (1) Prepare raw materials by weight:

[0050] 70 parts of PC resin; 30 parts of ABS resin; 2 parts of compatibilizer ABS-g-MAH; 0.5 parts of lubricant paraffin;

[0051] 5 parts of sulfonated SBS resin; the degree of sulfonation is 0.5 mmol / g.

[0052] (2) Dry PC resin at 100°C for 3 hours, and dry ABS resin at 110°C for 2 hours, then add compatibilizer, lubricant and sulfonated SBS and mix them evenly with a blender, and then use a screw extruder to heat and extrude , after extrusion, cooling and pelletizing can obtain alloy material particles.

[0053] The screw extruder can be divided into 9 heating zones, and the temperature is set at 220°C~230°C, 230°C~240°C, 240°C~250°C, 250°C~260°C, 260°C~270°C, 270°C~280°C ℃, 270℃~280℃, 260℃~270℃, head temperature 240℃~250℃; the speed of the feeding rod is 12r / min; the speed of the main screw is 350r / min.

[0054] The raw material of the pres...

experiment example 3

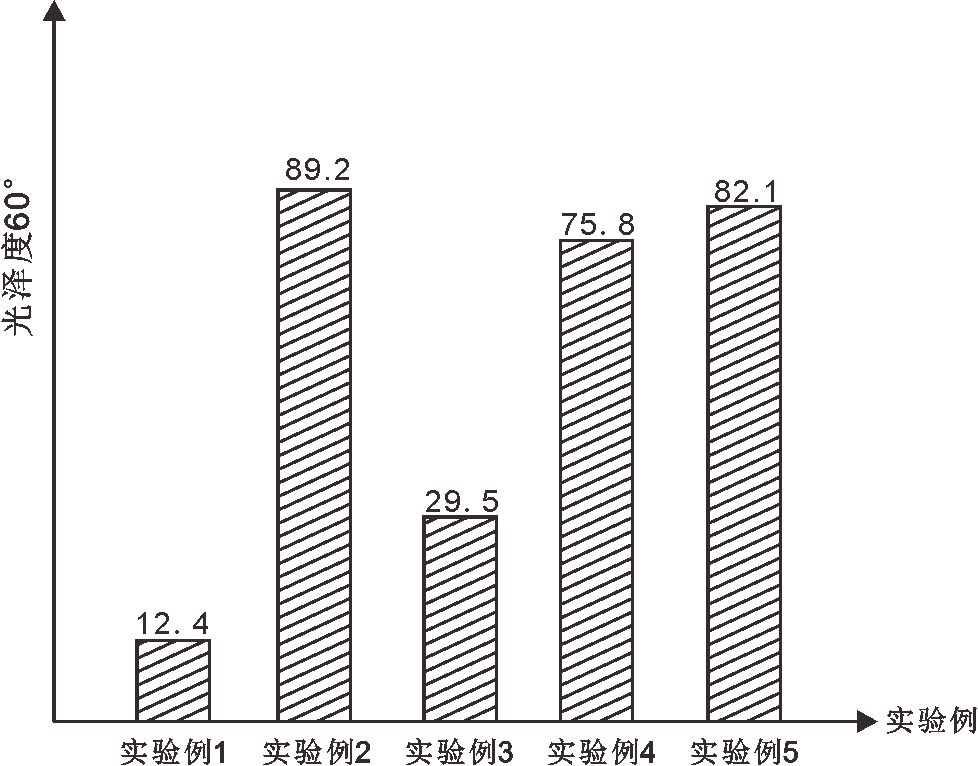

[0082] In Experimental Example 3, conventional SBS resin was added on the basis of Experimental Example 2, which can significantly reduce the gloss, indicating that the addition of conventional SBS can already make the alloy material have a certain matte effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com