Positive flow excavator power and torque distribution control method

A technology of torque distribution and control method, which is applied in earth mover/excavator, construction, etc., and can solve the problems of unstable load, large variation range, unstable engine load and speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

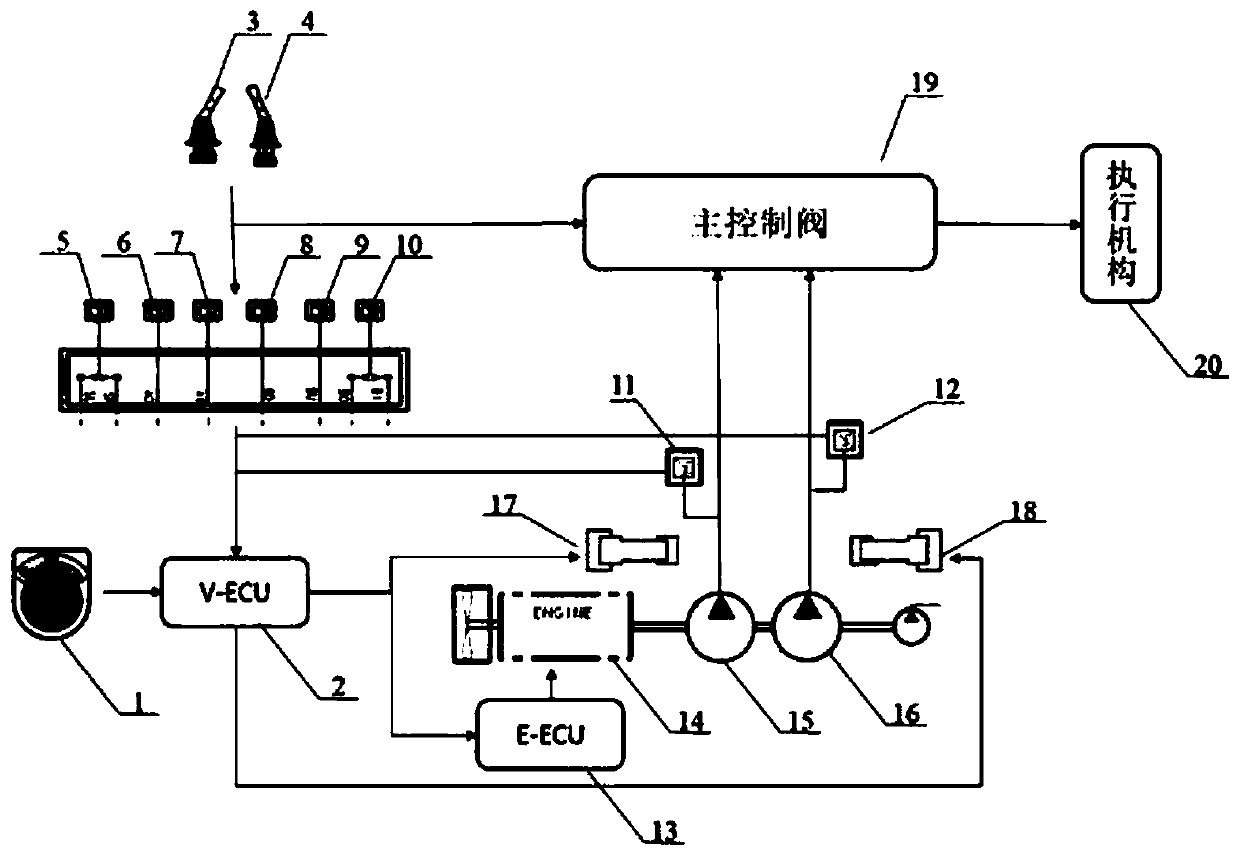

[0050] Such as Figure 1 to Figure 3 As shown, the power and torque distribution control method of a positive flow excavator, the excavator includes a gear selector 1, a main controller 2, a left pilot control valve 3, a right pilot control valve 4, a rotary pilot pressure sensor 5, an arm discharge Material pilot pressure sensor 6, stick digging pilot pressure sensor 7, boom lowering pilot pressure sensor 8, boom lifting pilot pressure sensor 9, bucket digging / discharging pilot pressure sensor 10, P1 pump pressure sensor 11, P2 pump Pressure sensor 12, engine controller 13, engine 14, P1 pump 15, P2 pump 16, P1 pump swash plate angle regulator 17, P2 pump swash plate angle regulator 18, main control valve 19, actuator 20, main pump, P1 pump electromagnetic proportional valve, P2 pump electromagnetic proportional valve, boom cylinder, arm cylinder, bucket cylinder, swing motor and travel motor, the excavator provides power to P1 pump 15 and P2 pump 16 through engine 14, and P1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap