Infrared automatic identification method for internal defect types of main beams of large wind turbine blades

A technology for automatic identification of wind turbine blades, applied to wind turbines, monitoring of wind turbines, machines/engines, etc., can solve the problems that infrared measurement methods cannot realize automatic analysis of defect types, and measurement methods are not suitable for on-site detection, etc., to achieve automatic The effect of high recognition accuracy, wide applicability, and expanded detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

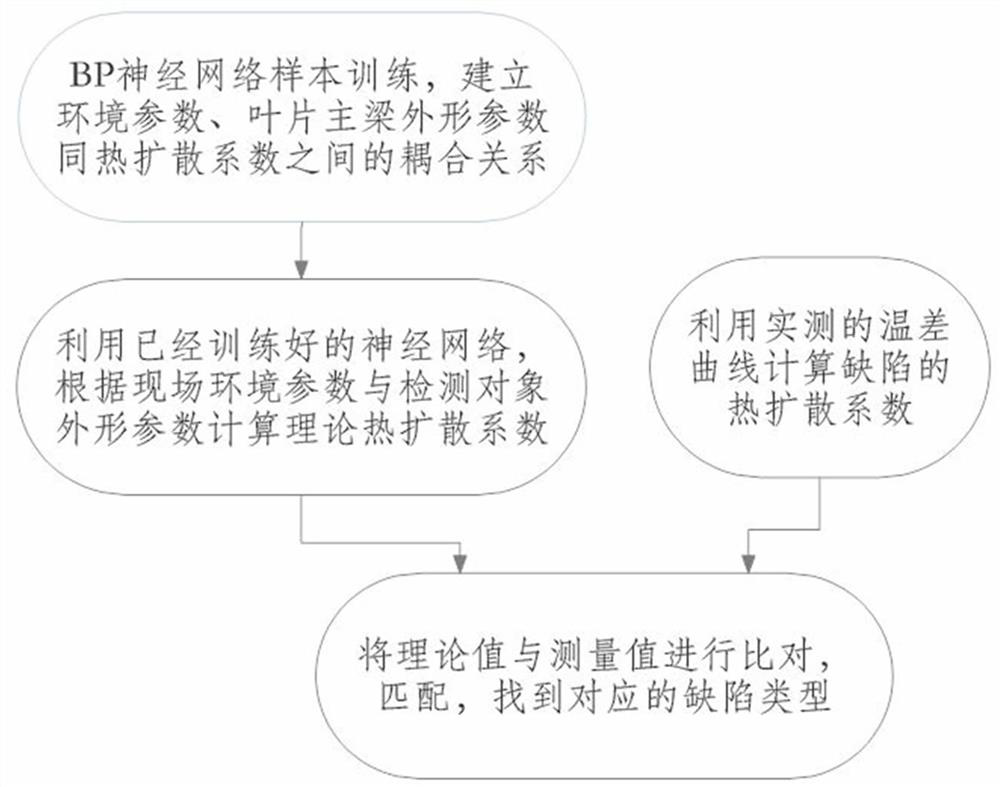

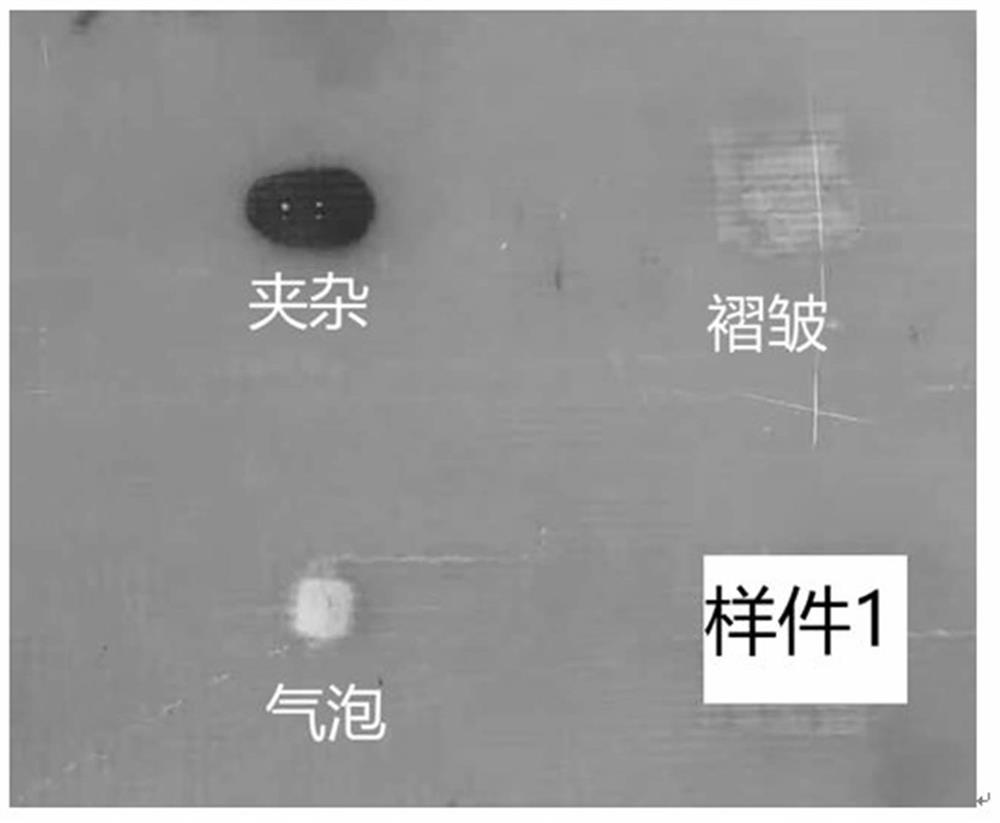

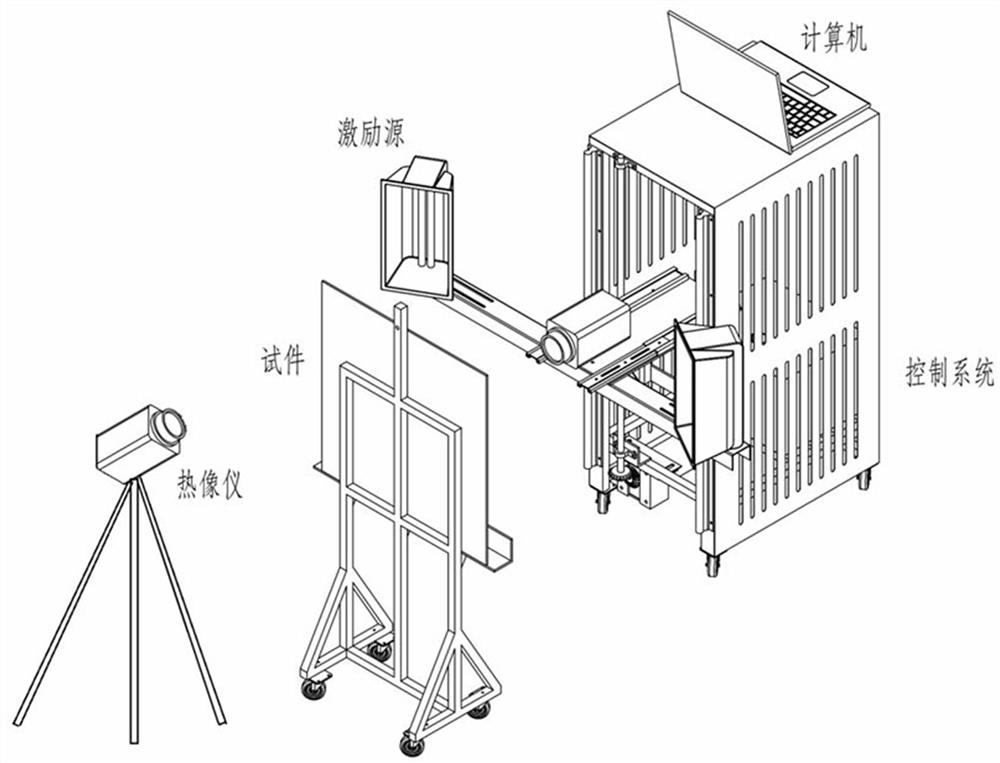

[0050] This application proposes an infrared automatic identification method for internal defect types of main girders of large wind turbine blades. Using BP neural network algorithm, it can solve the theoretical value of thermal diffusivity of different defect types in real time under the condition of known environmental parameters and blade geometric parameters, and realize automatic identification of several defect types by comparing the theoretical value with the measured value . In addition, by comparing the thermal diffusivity to distinguish the defect type, it solves the problem that it is difficult to distinguish the type of defects with similar infrared imaging effects, and the automatic recognition accuracy is high. Furthermore, using the nonlinear approximation function of the BP neural network algorithm, the coupling relationship between the thickness of the blade, the irradiation distance, the ambient temperature, the wind speed of the blade surface and the therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com