Hydraulic oil pump for engineering machinery

A hydraulic oil pump and engineering machinery technology, applied in the field of hydraulic oil pumps, can solve problems affecting the working efficiency of construction machinery, inconvenient use, and oil pumps that cannot be used normally, and achieve the effects of avoiding abnormal use, convenient use, and avoiding work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

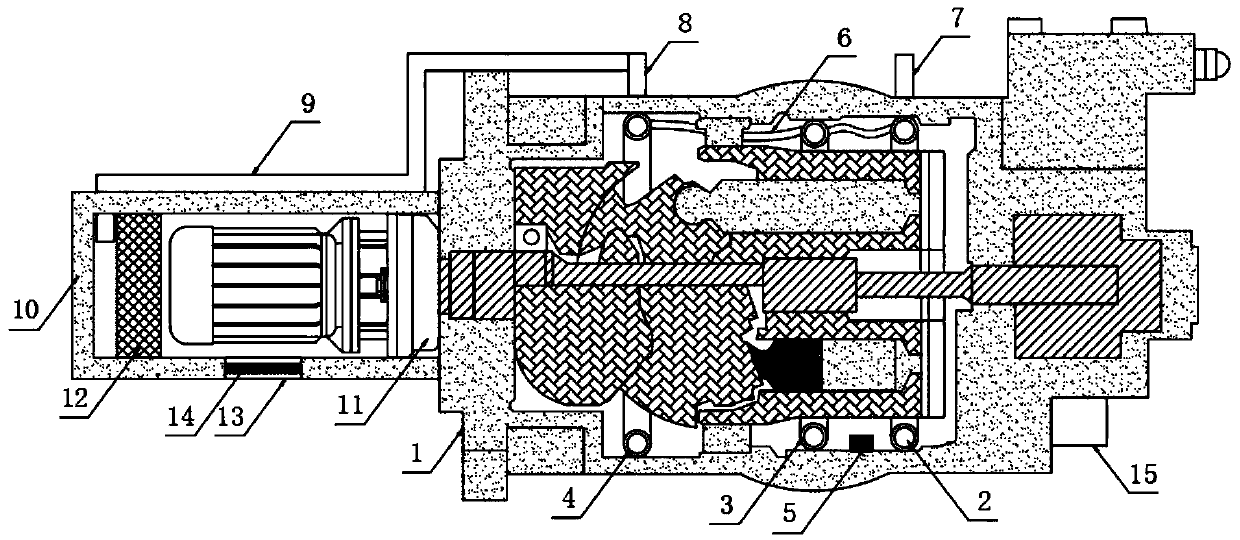

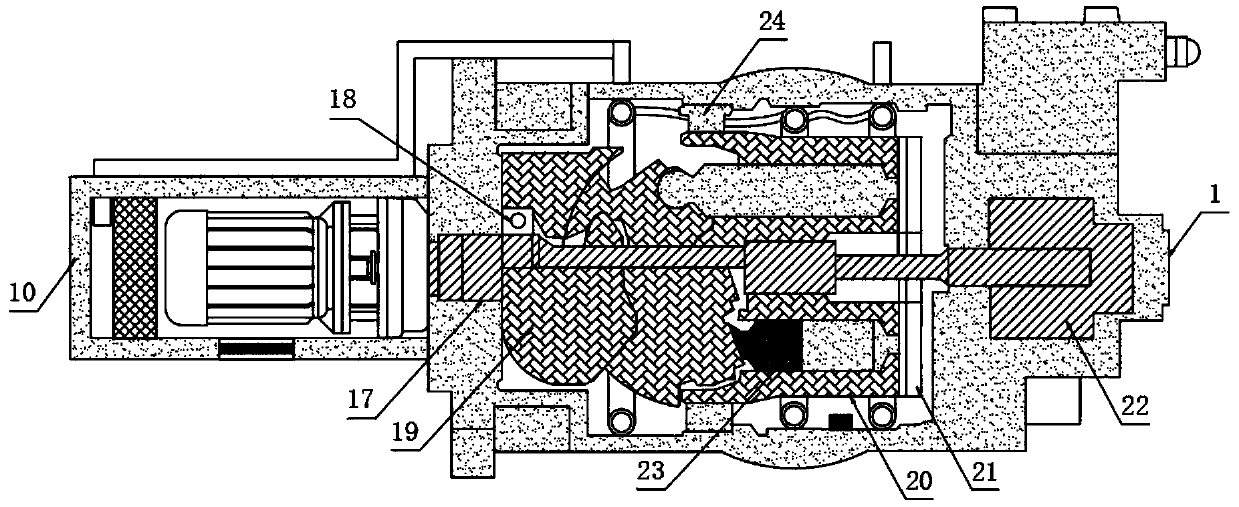

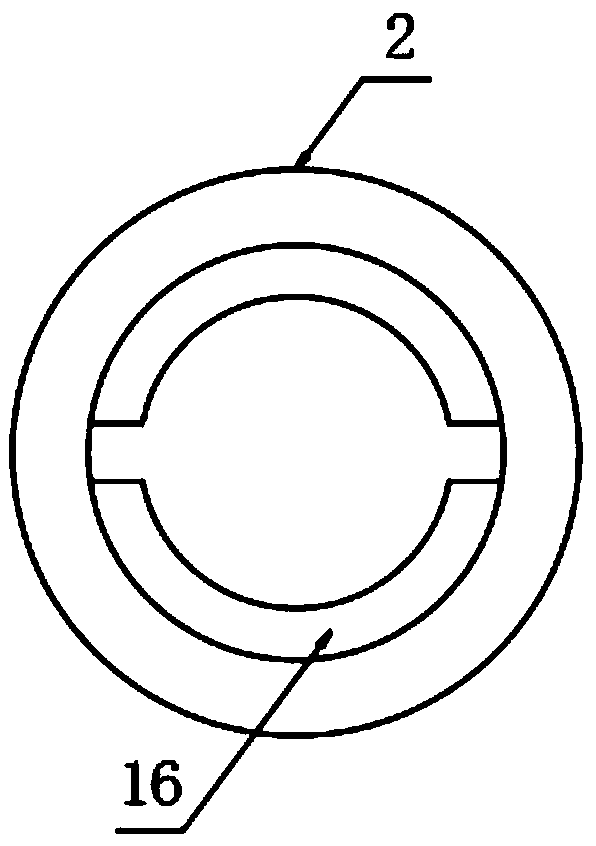

[0024] The present invention provides such Figure 1-3 A hydraulic oil pump for construction machinery shown includes a pump casing 1, a first annular copper pipe 2, a second annular copper pipe 3 and a third annular copper pipe 4 are arranged on the inner wall of the pump casing 1, and the first annular copper pipe 4 is arranged on the inner wall of the pump casing 1. A temperature detection unit 5 is arranged between the annular copper pipe 2 and the second annular copper pipe 3, between the first annular copper pipe 2 and the second annular copper pipe 3 and between the second annular copper pipe 3 and the third annular copper pipe 4 are connected with drainage hoses 6, and the inner walls of the first annular copper pipe 2, the second annular copper pipe 3 and the third annular copper pipe 4 are fixed with cooling fins 16, and the top of the pump casing 1 is provided with There is an air outlet 7 and an air inlet 8, the air inlet 8 is located on the side of the air outlet ...

Embodiment 2

[0027] Further, in the first embodiment above, the second annular copper pipe 3 is arranged on the side of the first annular copper pipe 2 , and the third annular copper pipe 4 is arranged on the side of the third annular copper pipe 4 .

[0028] Further, in the above-mentioned embodiment 1, the first annular copper pipe 2, the second annular copper pipe 3, the third annular copper pipe 4 and the temperature detection unit 5 are all fixedly connected to the inner wall of the pump casing 1, so as to facilitate the An annular copper pipe 2, a second annular copper pipe 3, a third annular copper pipe 4 and a temperature detection unit 5 are fixed.

[0029] Further, in the above-mentioned embodiment 1, the gas outlet 7 runs through the top of the pump casing 1 and extends to the inside of the pump casing 1 to communicate with the first annular copper pipe 2, so that the gas inside the first annular copper pipe 2 can be released from the outlet. Port 7 is exhausted.

[0030] Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com