Mechanism capable of simultaneously performing circumferential rotation and axial movement

A technology of axial movement and inner rotating shaft, applied in the directions of engine components, mechanical equipment, fluid pressure actuating devices, etc., can solve the problems of large relative sliding amount, difficult sealing, small application range, etc., and achieve short axial length, Good sealing effect and the effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

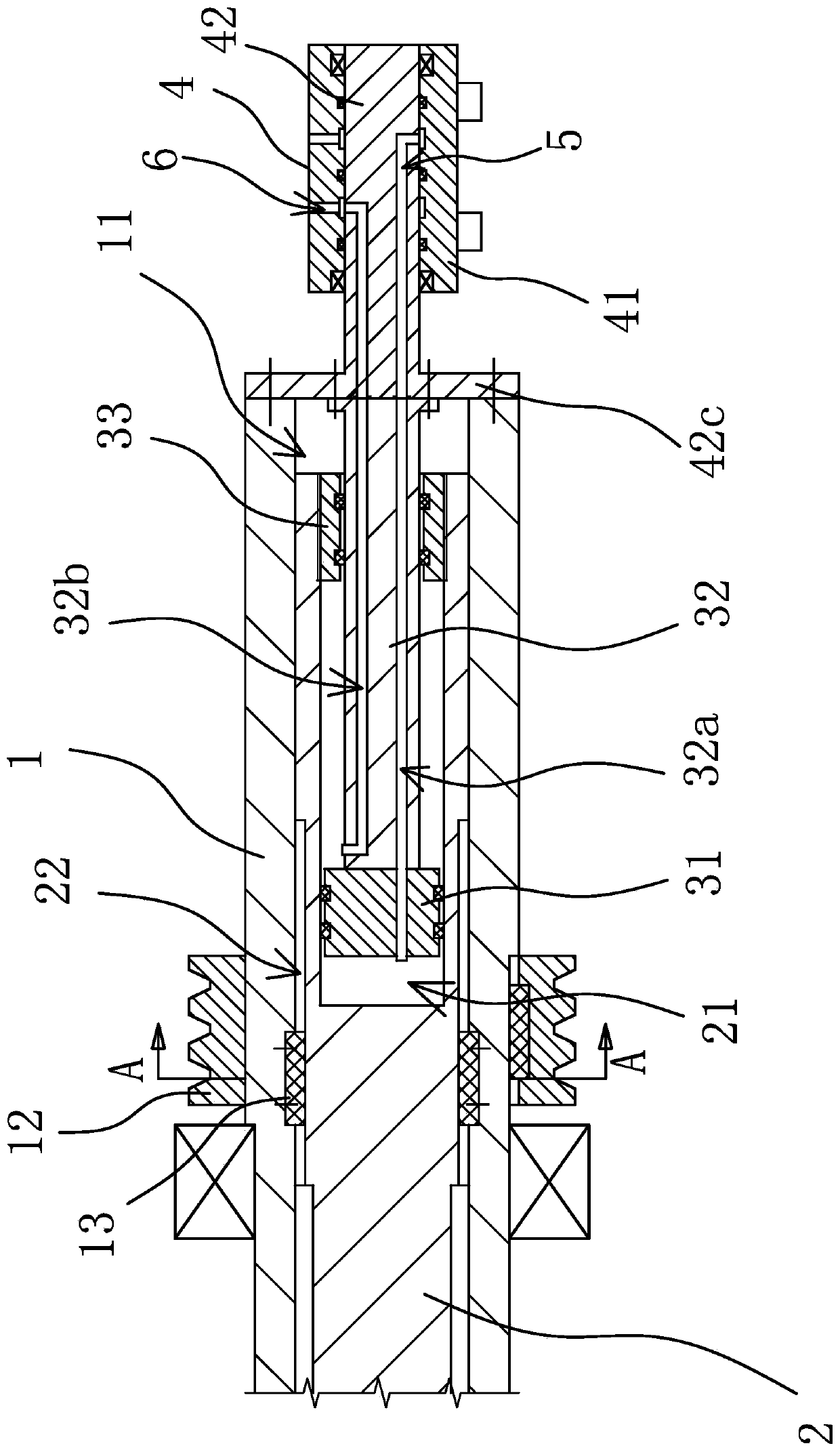

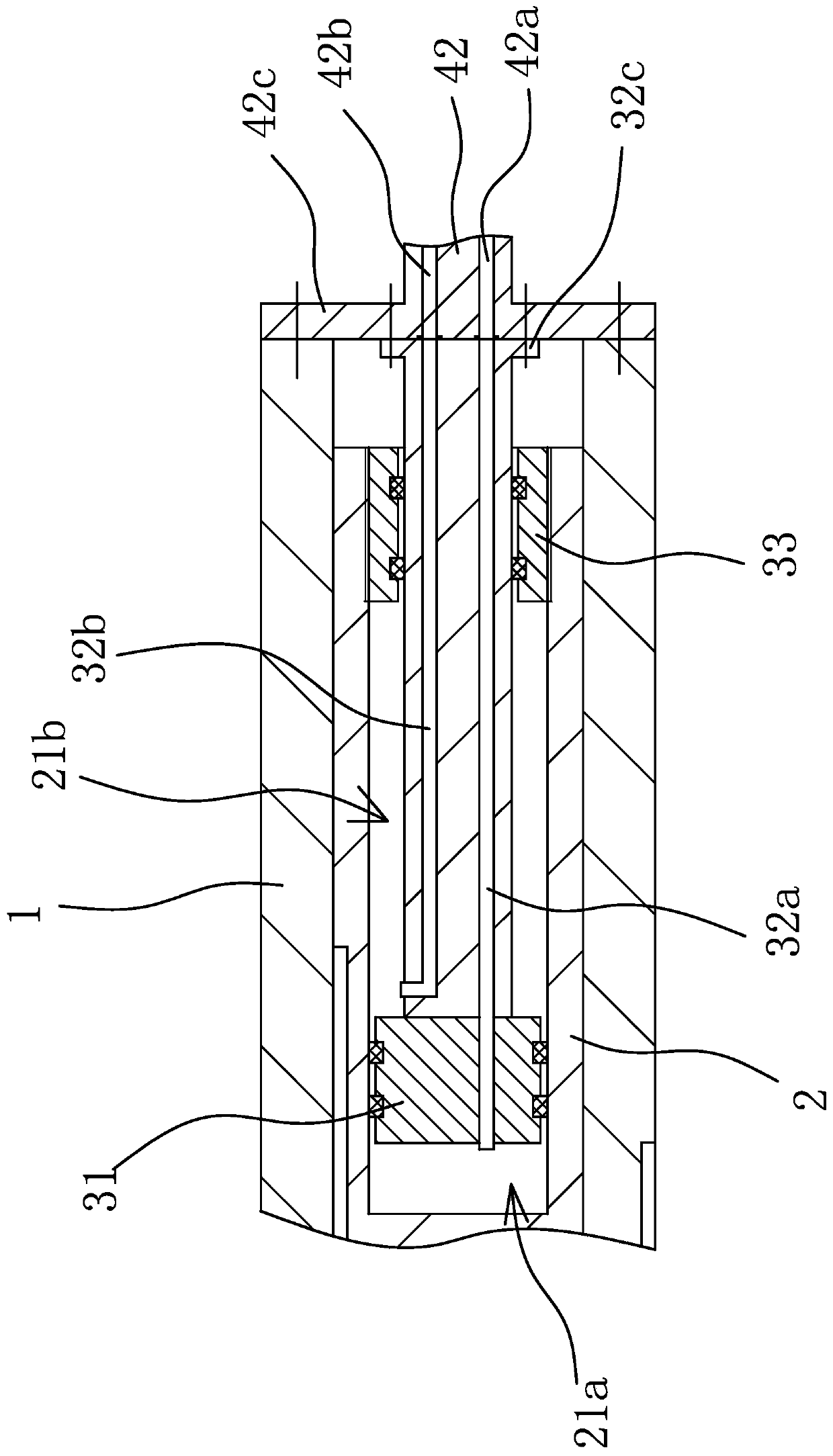

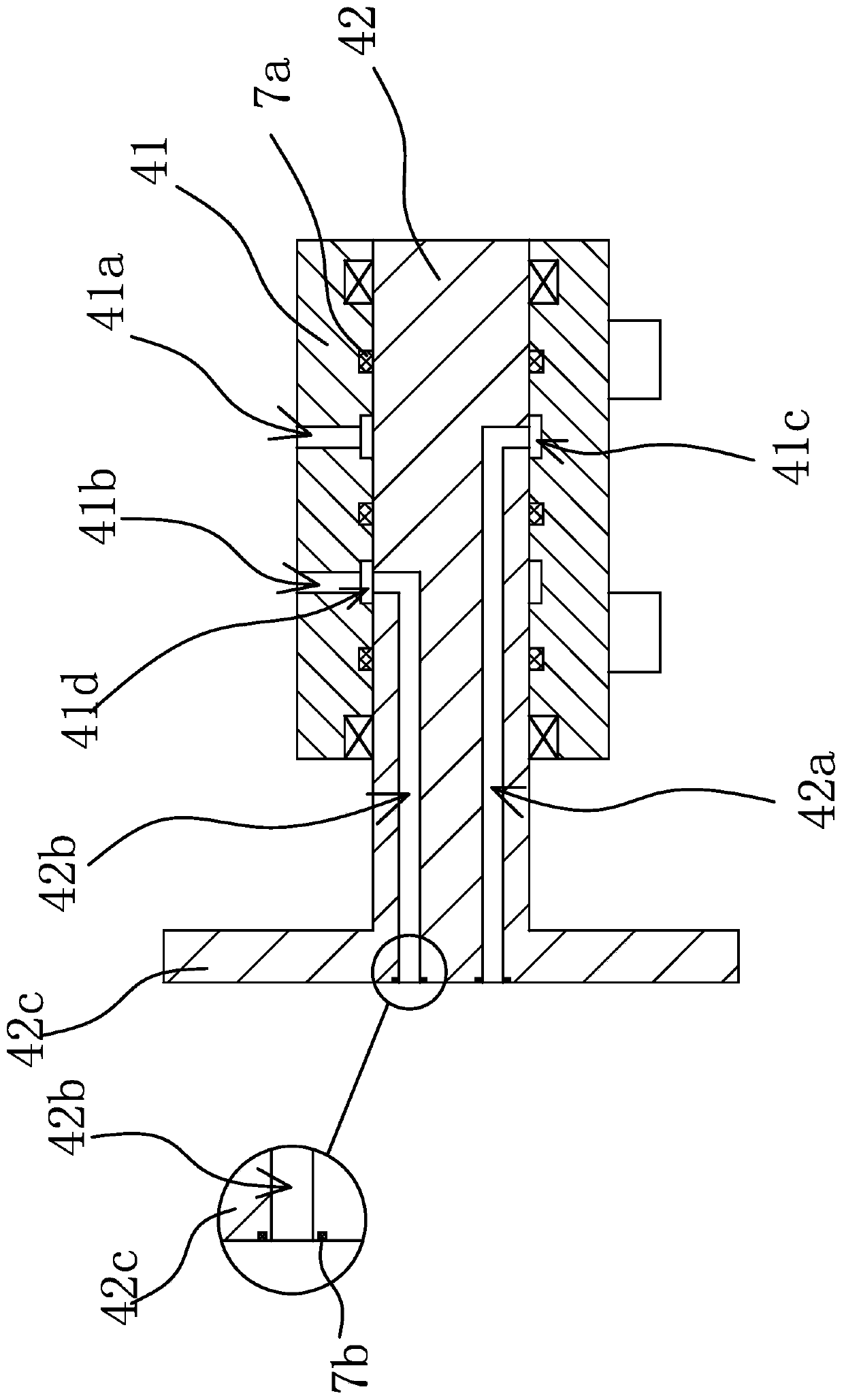

[0025] Such as figure 1 , figure 2As shown, a mechanism that can simultaneously perform circumferential rotation and axial movement includes an outer shaft 1 and an inner shaft 2. The outer shaft 1 is a cylindrical structure provided with a central hole 11 along the axis, and the inner shaft 2 passes through a key. Fitted in the central hole 11, one end of the inner rotating shaft 2 is axially opened with a blind hole 21, the blind hole 21 is provided with a piston 31 and a piston rod 32 connected with the piston 31, the piston 31 separates the blind hole 21 to form a second One oil chamber 21a and the second oil chamber 21b, the end of the piston rod 32 away from the piston 31 protrudes out of the inner shaft 2 and is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com