Enhanced 300MW circulating fluidized bed boiler deslagging pipe inlet smooth-deslagging device and installation method

A technology of circulating fluidized bed and slag discharge pipe, which is applied in the direction of fluidized bed combustion equipment, combustion method, fuel burned in molten state, etc. It can solve the problems of hindering slag discharge, accumulation of bed material, and small inner diameter of slag discharge pipe, etc. To achieve the effect of increasing welding performance and strength, improving service life and good penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

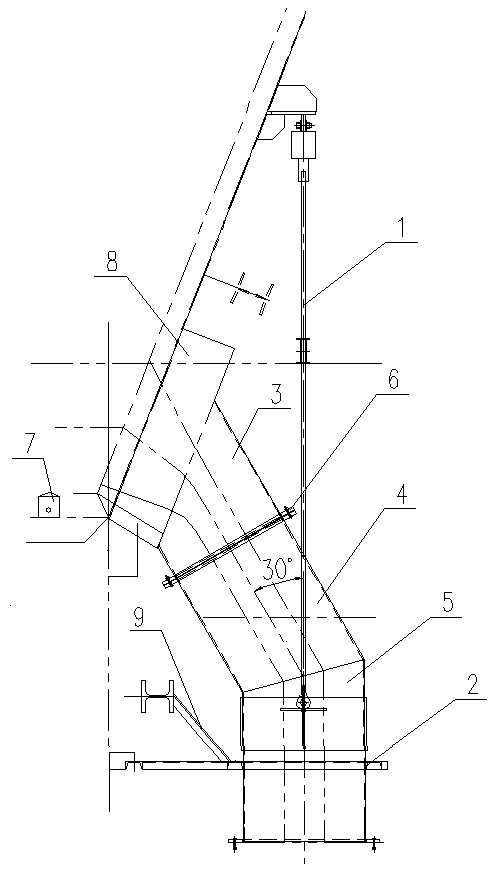

[0022] A device for enhancing the smooth slagging at the entrance of the slag discharge pipe of a 300MW circulating fluidized bed boiler. I3, the cylinder I is connected to the cylinder II4 through the connecting flange 6, the cylinder II and the cylinder III5 are fixed by welding, the outer wall of the cylinder III is equipped with a support guide 2, the cylinder III A sealing box 8 is welded on the upper slope of the cylinder 1, the outer side of the sealing box is fixed to the steel beam of the boiler, one end of the hanging device 1 is connected to the boiler supporting beam through bolts, and the other end of the hanging device is connected to the steel beam of the boiler through a lug. The outer wall of the cylinder III is connected, and a wind cap 7 is installed at the central line of the entrance of the slag discharge pipe at a distance of 150 mm from the lower part of the slag discharge pipe.

Embodiment 2

[0024] According to the enhanced slag discharge device for a 300MW circulating fluidized bed boiler at the entrance of the slag discharge pipe described in Example 1, one end of the support angle steel 9 is fixed on the side of the support guide device, and the other end of the support angle steel is connected to the boiler support beam , a sealing ring is installed between the connecting flanges.

Embodiment 3

[0026] A method for installing a smooth slag discharge device at the entrance of the enhanced 300MW circulating fluidized bed boiler slag discharge pipe described in Embodiment 1-2, the method includes the following steps:

[0027] Set the angle and vertical direction of the slag pipe to 30°, the inner diameter of the slag pipe to 300mm, and install a wind cap at the entrance of the slag pipe;

[0028] Installation of slag pipe:

[0029] Step 1. Install the vertical section cylinder III in the support guide device, the size is 754 diameter x 8mm thickness, and the material is Q235. Then weld the stainless steel grab nails with a length of 210mm, and then choose a 300mm plastic pipe to install on the center line of the slag pipe. Finally, pour refractory and wear-resistant corundum plastic on the outside of the plastic pipe and the inside of the slag pipe;

[0030] Step 2, install variable spring hangers on the left and right sides of the slag pipe;

[0031] Step 3, welding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com