Full-automatic running-in testing machine for steering gear

A fully automatic and testing machine technology, which is applied in the testing of machines/structural components, instruments, mechanical components, etc., can solve the problems that cannot meet the requirements of fully automated production lines, and reduce the workload of workers, save labor, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

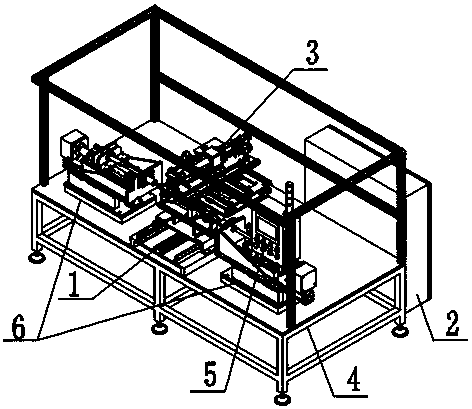

[0014] refer to figure 1 As shown, the steering gear automatic forward and reverse test machine of the present invention is composed of an automatic moving in and out mechanism 1, a PLC electrical control box 2, a loading mechanism 3, a frame 4, a touch screen control panel 5, and a running-in mechanism 6. The automatic moving in and out mechanism 1 and The frame 4 is connected by a bolt group; the PLC electrical control box 2 and the touch screen control panel 5 are connected by a data bus; the loading mechanism 3 is connected to the frame 4 by a bolt group; the running-in mechanism 6 is connected to the frame 4 by bolts; The running-in mechanism 6 is respectively connected with the touch screen control panel 5 and the PLC electrical control box 2 through data lines;

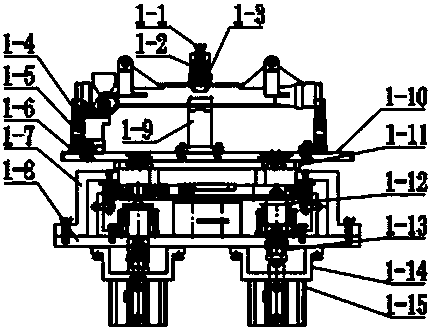

[0015] refer to figure 2 As shown, the upper pressure head seat 1-2 is connected with the upper pressure head 1-1 through the knob plunger 1-1; the housing support block 1-4 is connected with the quick change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com