Suspension system for single-axis optical actuators

An optical actuator and single-axis technology, applied in optics, instruments, projection devices, etc., can solve the problems of volume limitation, increase of manufacturing cost, volume can no longer be reduced or thinned, etc., to achieve reliable and convenient assembly and accurate angle And the effect of durability, collocation and easy action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

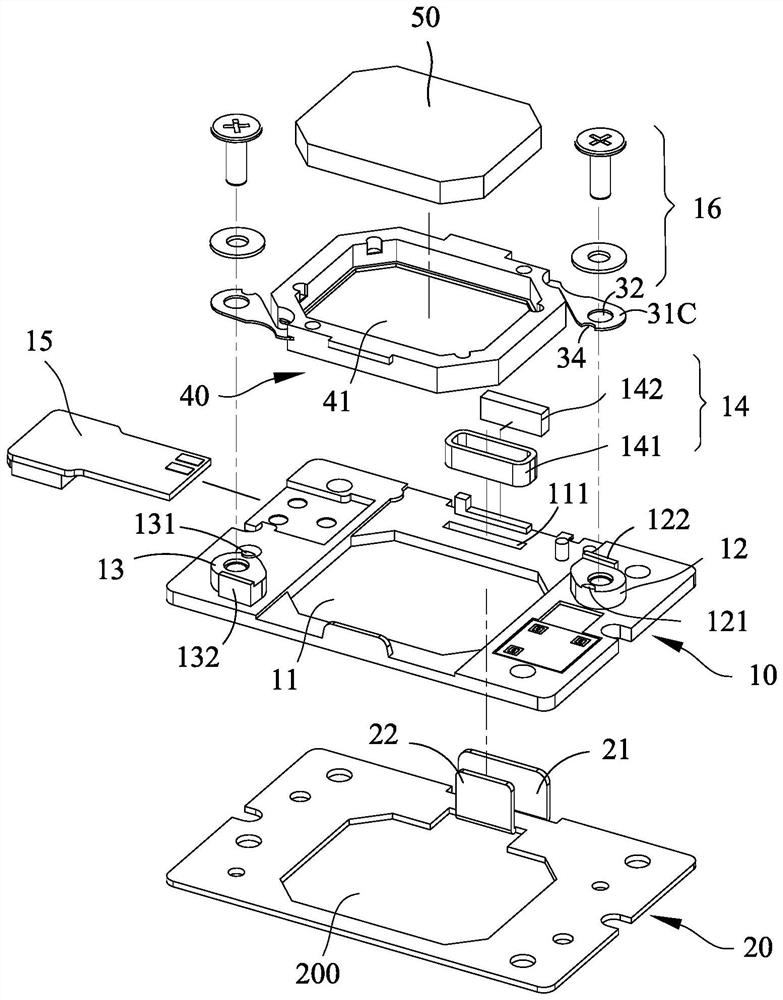

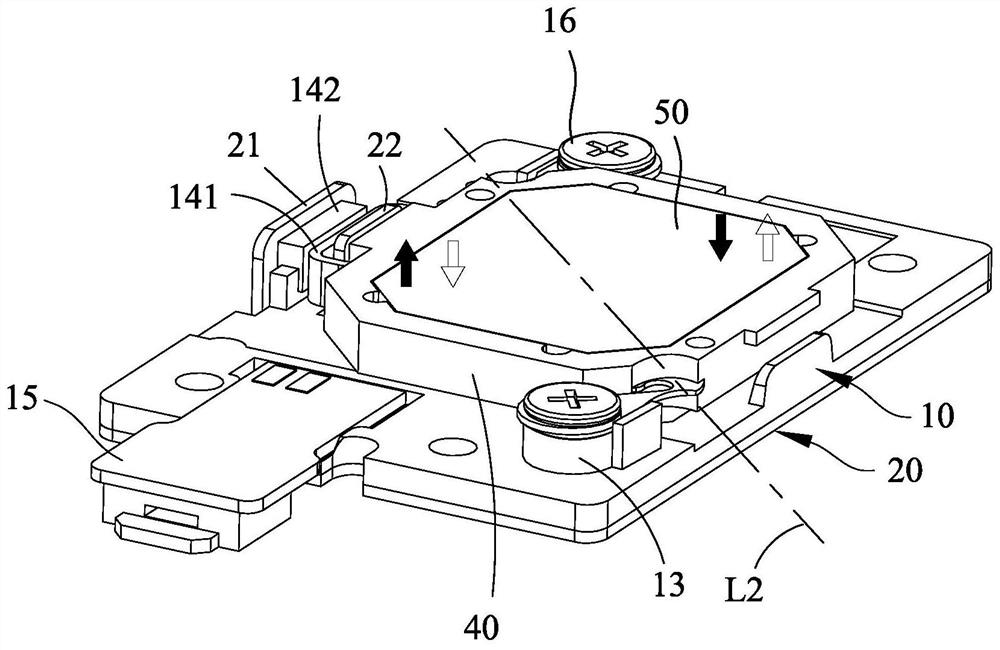

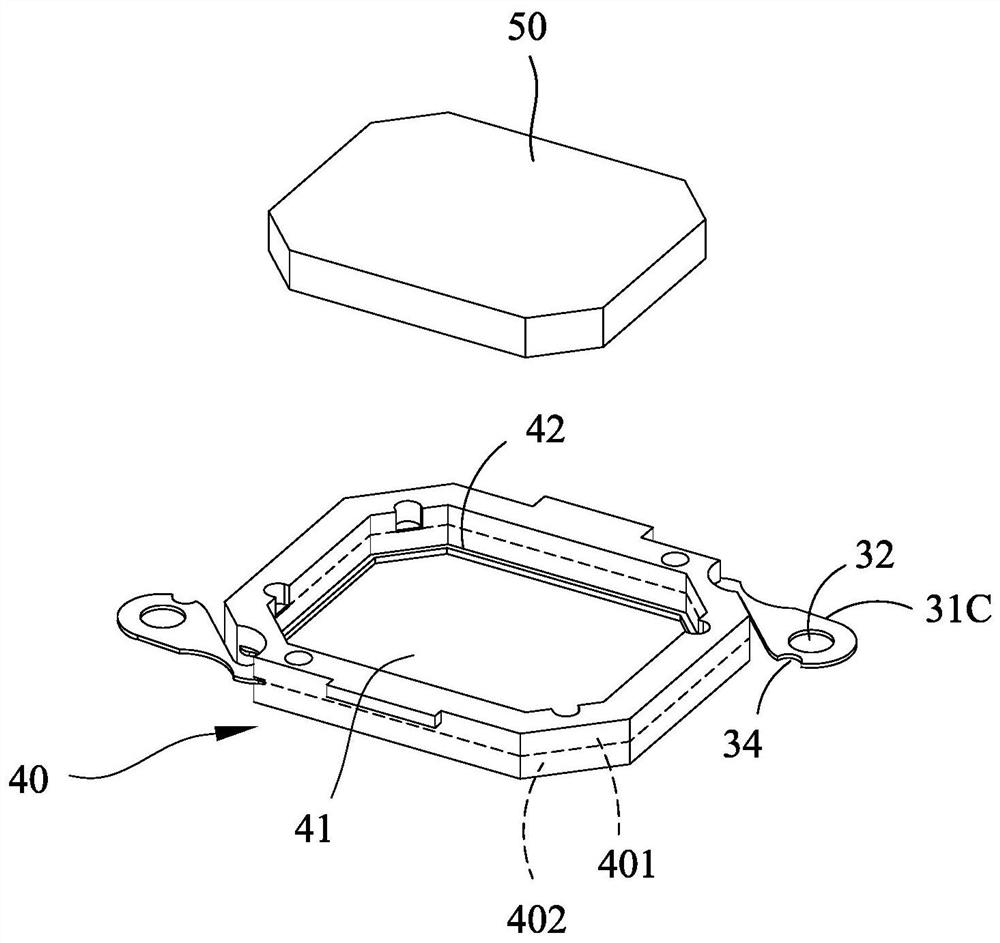

[0051] Please see figure 1 , figure 2 As shown, it is the first embodiment of the application of the suspension system of the single-axis optical actuator of the present invention, which at least includes:

[0052] A base 10 is provided with a square first light-transmitting hole 11 in the center, and on opposite sides of the diagonal line of the first light-transmitting hole 11, a pillar 12, 13 is protruded respectively, and the two pillars 12, 13 13 Positioning marks 121, 131 are provided on one side of the end (the present invention takes positioning tenons as an embodiment), and a positioning baffle 122, 132 is provided on the other side, and the square first light-transmitting hole 11 A set of magnetic devices 14 (composed of coils and magnets) is arranged beside a long side of the base 10, and a connector 15 is arranged at the end of the base 10.

[0053] A reinforcement frame 20, preferably metal, is located under the base 10, and is provided with a second light-tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com