Display manufacturing apparatus and manufacturing method thereof

A technology for display components and manufacturing methods, applied to identification devices, nonlinear optics, instruments, etc., can solve problems such as difficult to form steps, high weight pressure, poor appearance, etc., to prevent pressing marks, prevent damage, prevent bad appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Next, an embodiment of a display member manufacturing apparatus and a manufacturing method thereof according to the present invention will be described with reference to the drawings. In describing the display component manufacturing apparatus and its manufacturing method, the thickness of lines or the size of constituent elements shown in the drawings may be exaggerated for clarity and convenience of description. In addition, terms described later are terms defined in view of functions in the present invention, and may be different according to user's or operator's intention or habit. Therefore, such terms should be defined based on the contents throughout the specification.

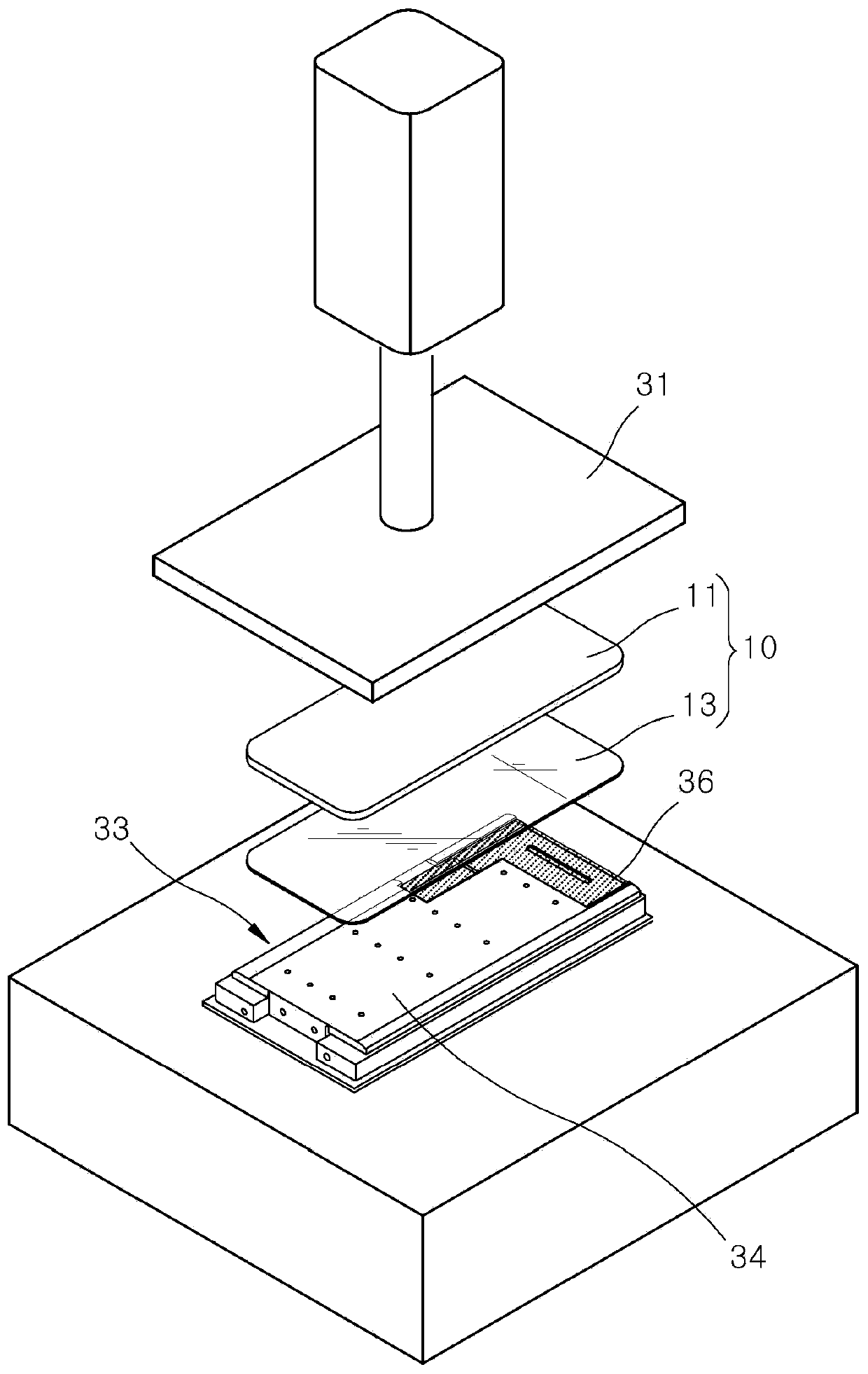

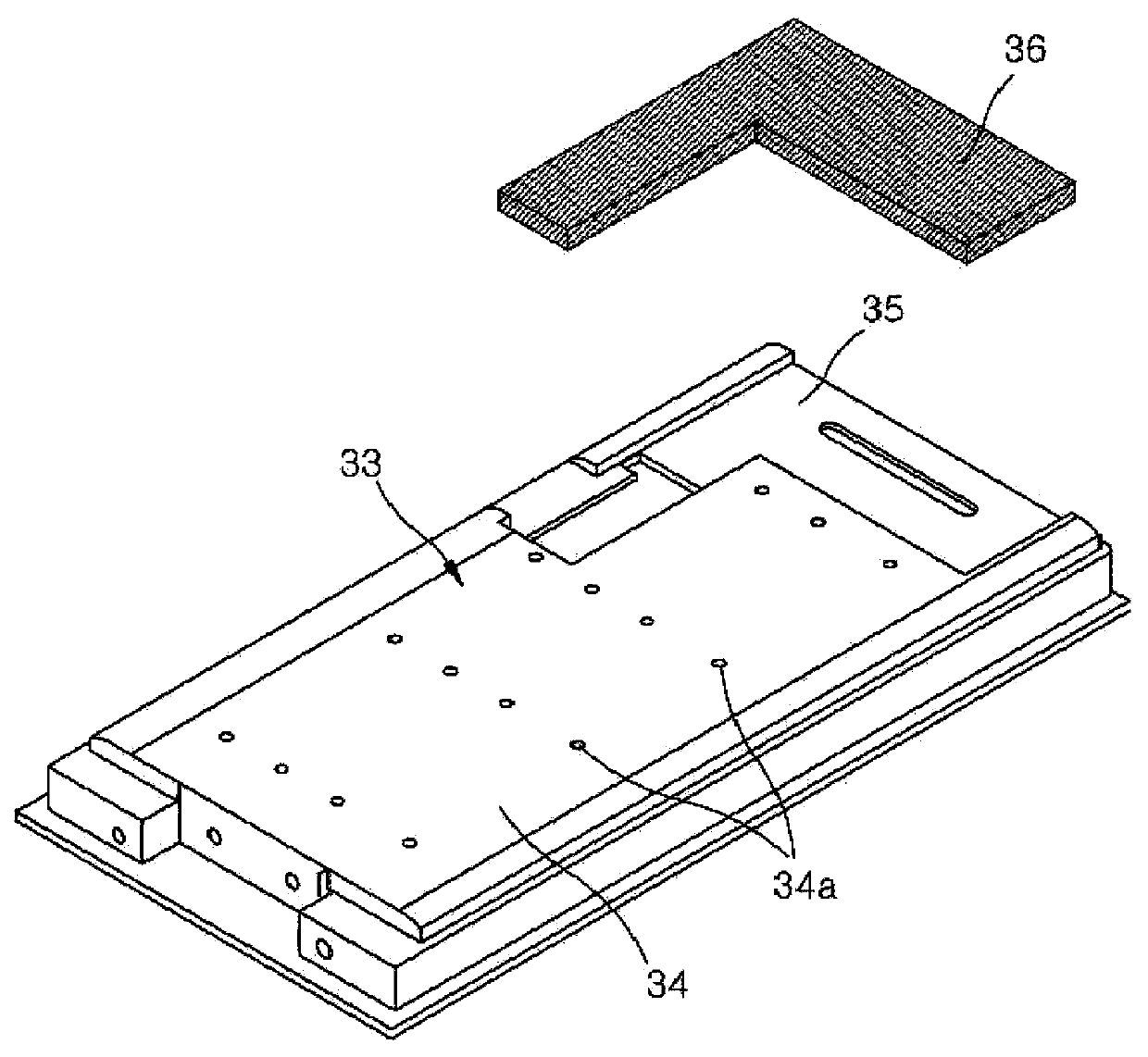

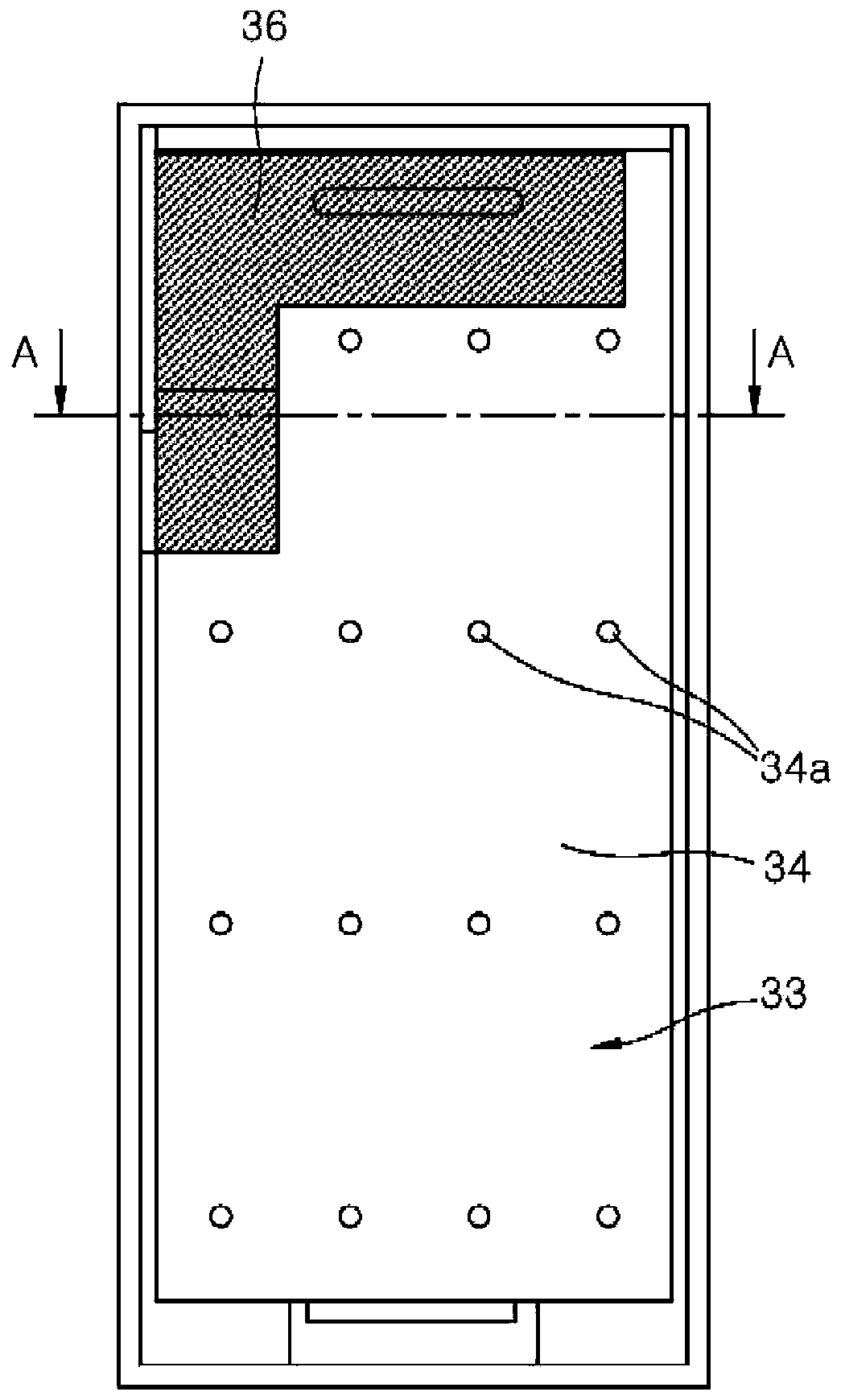

[0042] figure 1 is a perspective view showing a joining punch part and a joining table part according to an embodiment of the present invention, figure 2 is a perspective view showing a joint table portion and a damage prevention portion according to an embodiment of the present invention, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com