Method for preparing display substrate and display substrate

A technology for display substrates and display panels, which is used in semiconductor/solid-state device manufacturing, identification devices, semiconductor/solid-state device components, etc., can solve problems such as affecting the display effect of the display screen, and achieve the effect of avoiding the reduction of reflection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

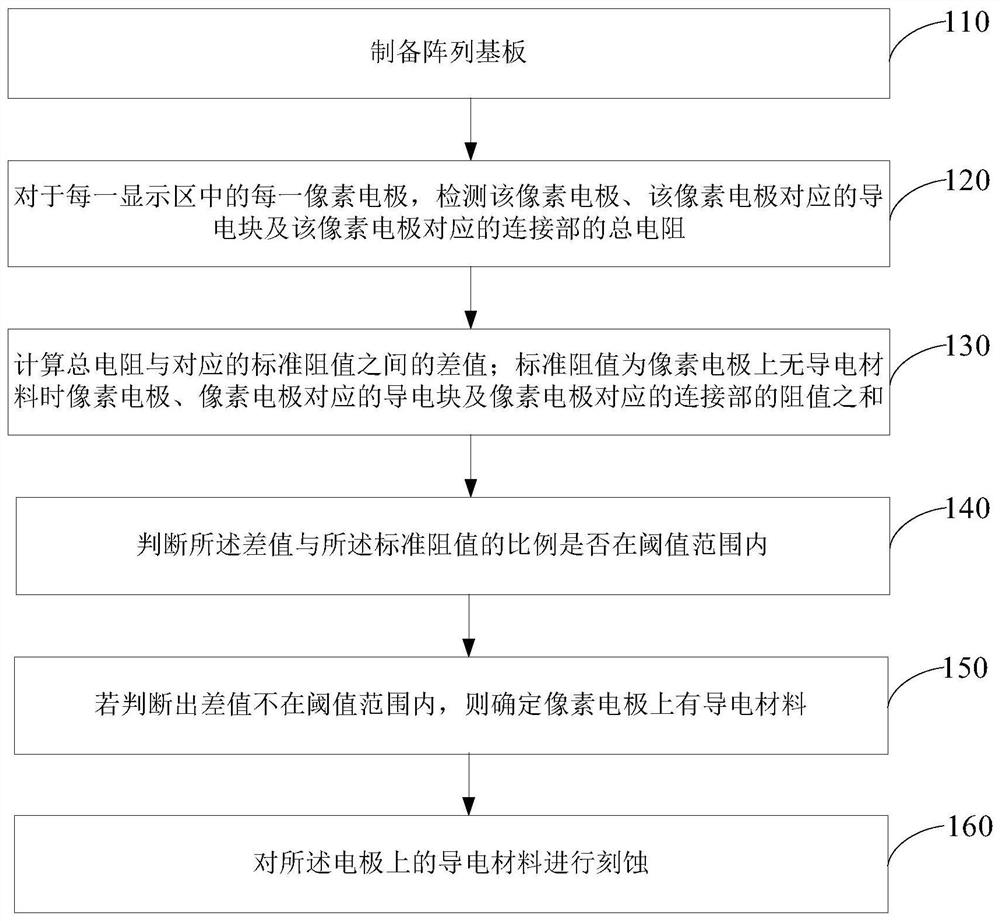

Method used

Image

Examples

Embodiment Construction

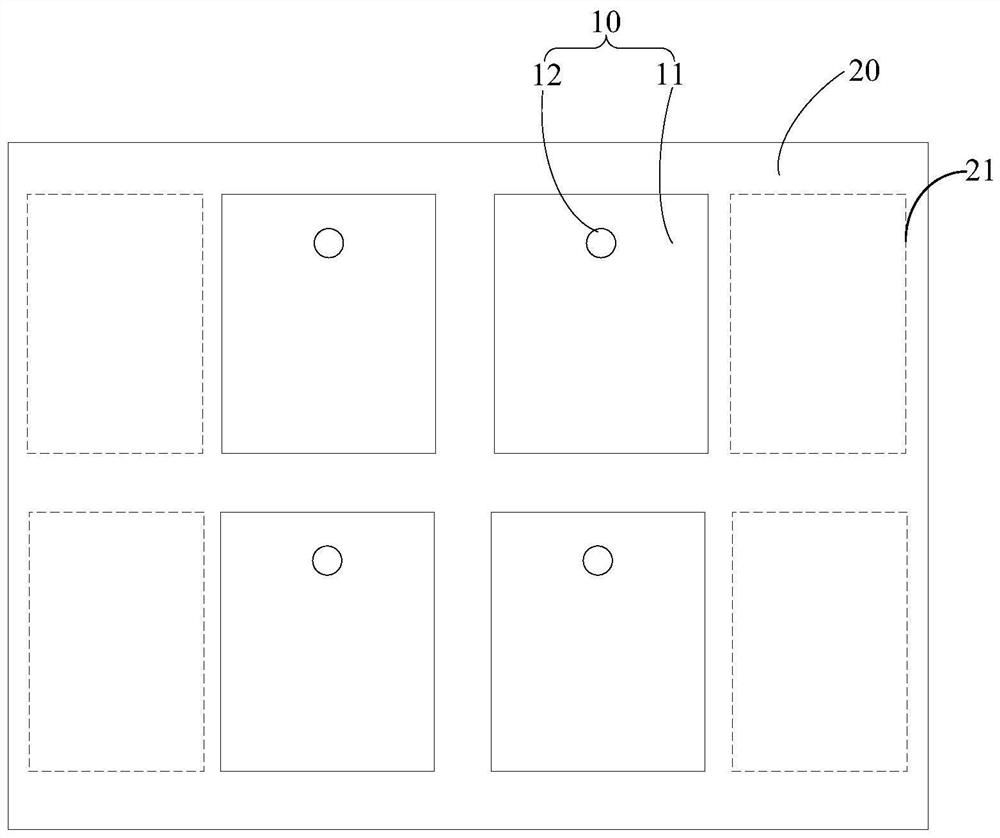

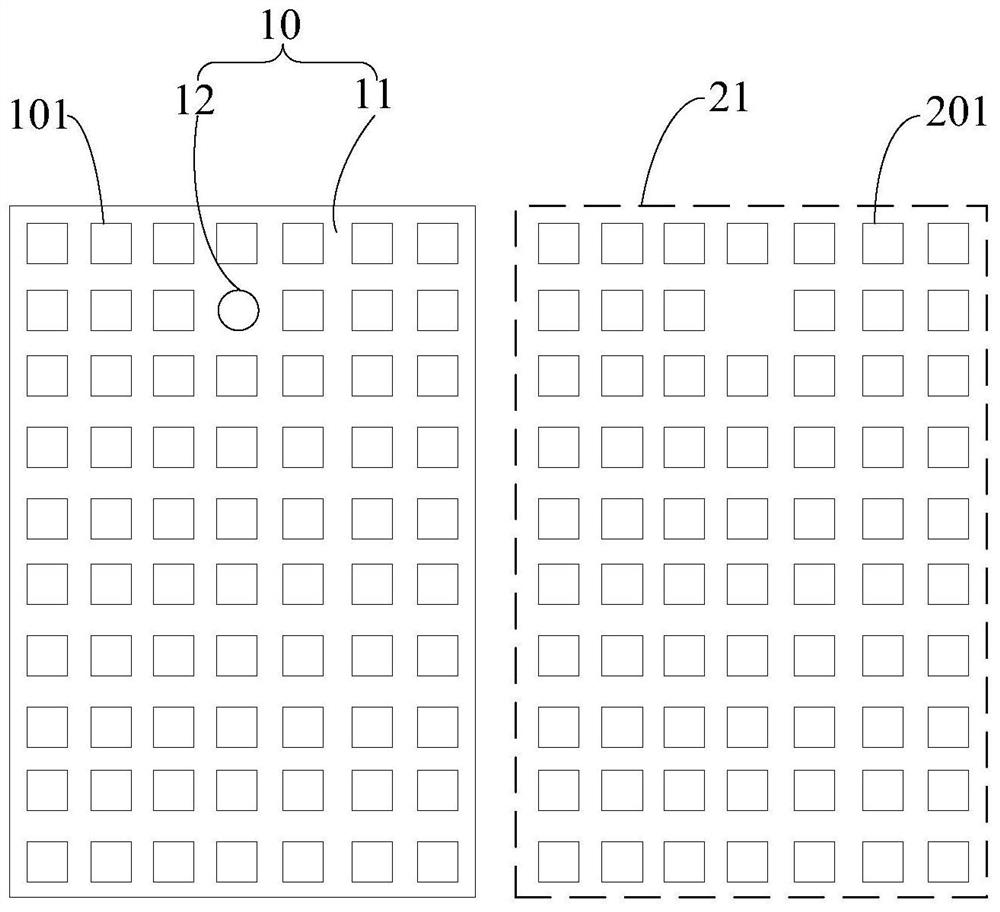

[0054] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated. The implementations described in the following exemplary embodiments do not represent all implementations consistent with this application. Rather, they are merely examples of means consistent with aspects of the present application as recited in the appended claims.

[0055] As mentioned in the background art, a protective film layer is formed on the pixel electrodes of the pixels in the display screen before opening the holes. After opening, the protective film layer is removed. Generally, wet etching can be used to remove the protective film layer, but due to fluctuations in process conditions or a decrease in the concentration of the etchant in the later stages of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com