Automatic cutting and blanking equipment for steel pipe joint long pipe

A steel pipe joint and automatic cutting technology, applied in shearing machine equipment, metal processing equipment, pipe cutting devices, etc., can solve the problems of frequent disassembly, low work efficiency, high cost of cutting and processing steel pipe joints and long pipes, and reduce the labor of workers. Strength, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

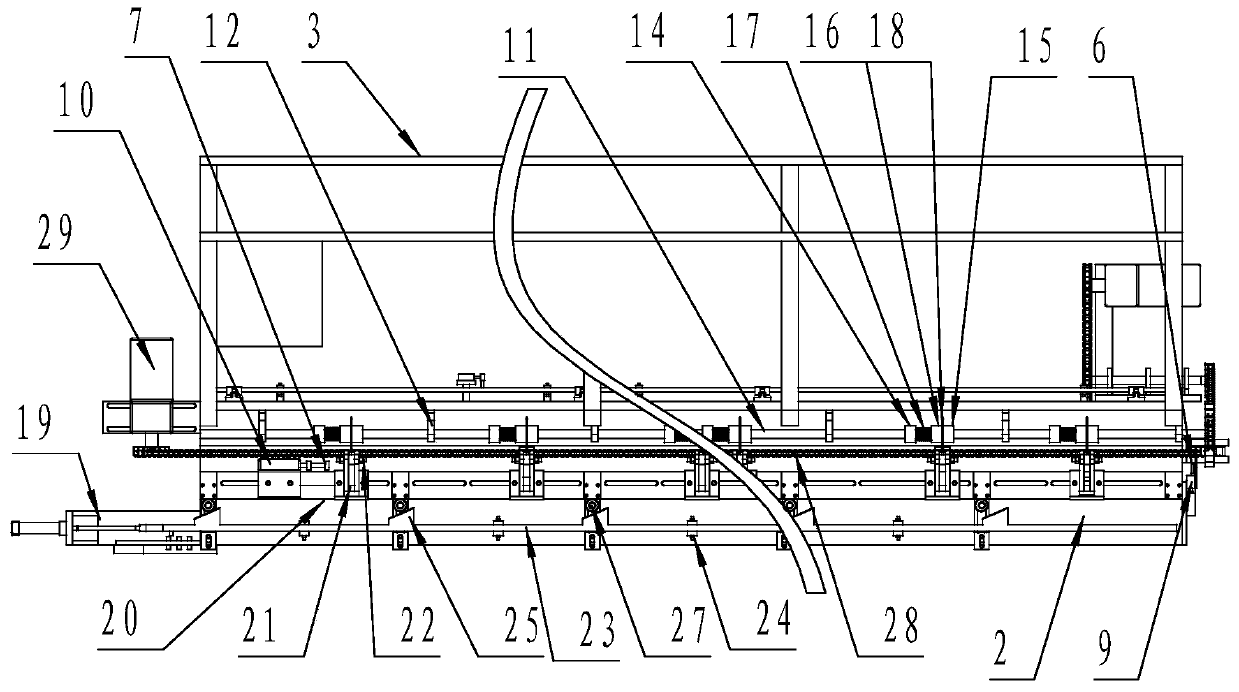

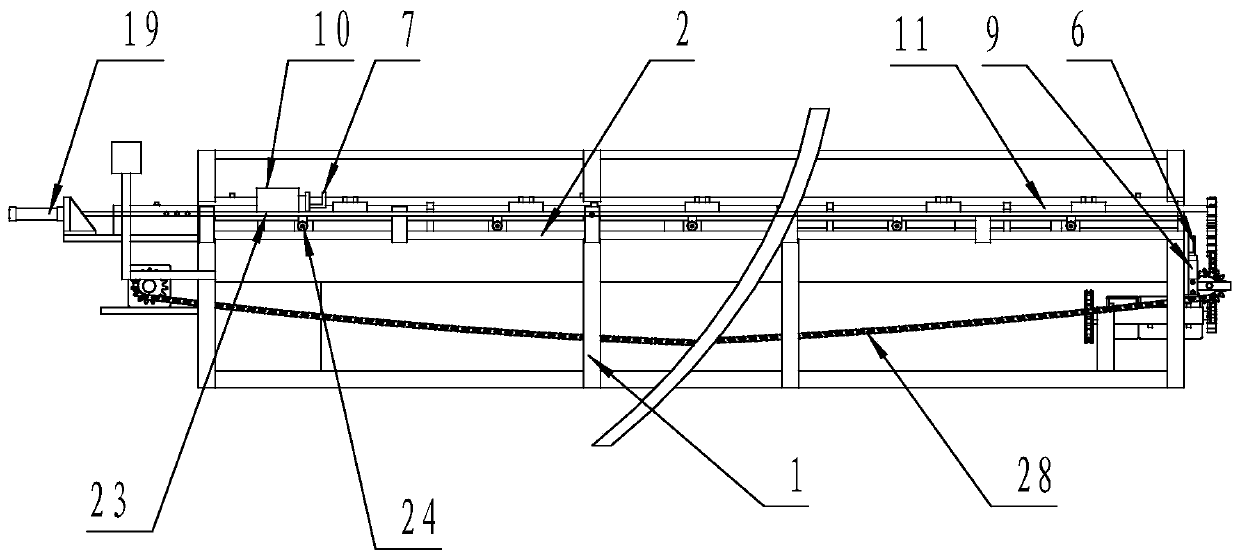

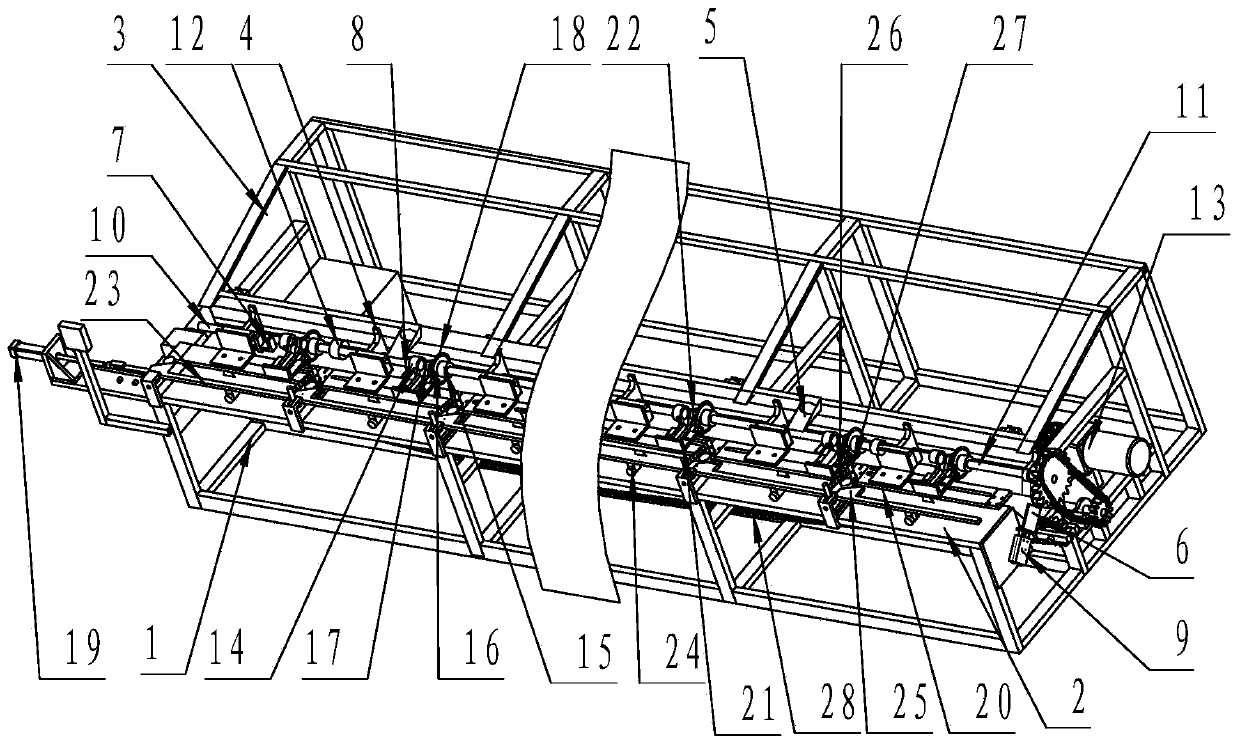

[0021] Such as figure 1 , figure 2 , image 3 As shown, an automatic cutting and blanking equipment for long steel pipe joints, including a hollow bar rack 1, a bar workbench 2 installed on the top surface of the hollow bar rack 1, and a rear side installation of the hollow bar rack 1 The original steel pipe storage bracket 3 with an inclined top surface is characterized in that: the original steel pipe storage bracket 3 with an inclined top surface is adjacent to the hollow strip frame 1 and is successively provided with vertical 7 bar-shaped baffles 4 that block the sliding of the steel pipe original pipe (the operator faces the invention, the left side of the operator is the left side of the hollow bar-shaped rack, and the right side of the operator is the right side of the hollow bar-shaped rack; close to the operator The side of the operator is the front side of the bar-shaped workbench, and the side away from the operator is the back side of the bar-shaped workbench),...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap