Jig device of handle-arranged tool assembling equipment

A technology for assembly equipment and shank tools, which is applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as the inability to realize automatic production, achieve compact structure, avoid accidents, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

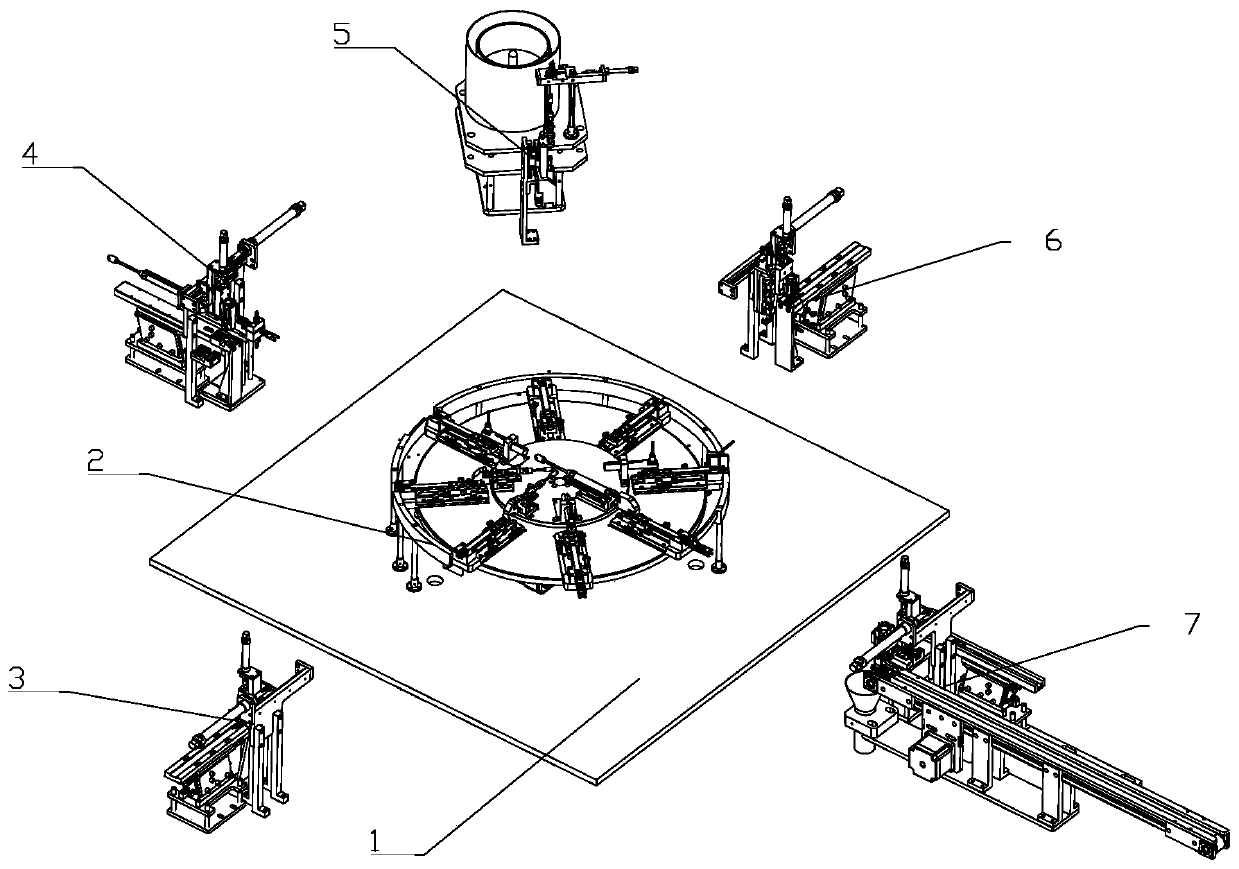

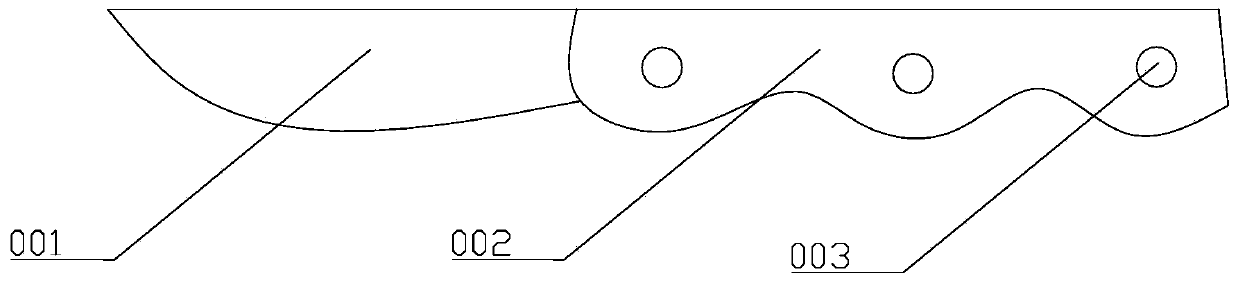

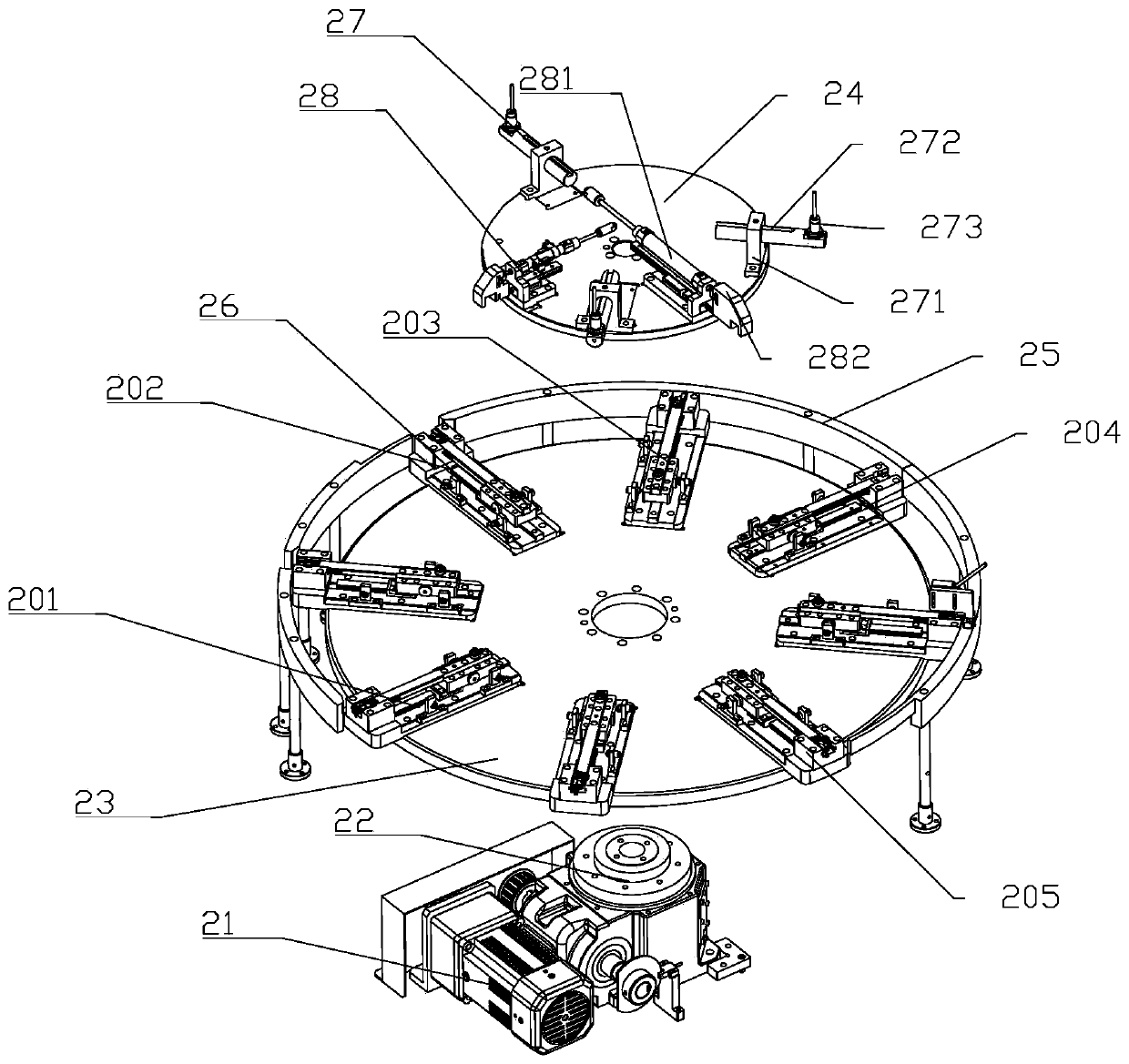

[0023] like figure 1 As shown, a kind of shank tool assembly equipment includes a frame 1 and a jig device 2 installed on the frame 1, a first handle feeding device 3, a blade feeding device 4, a pin assembly device 5, a second Knife handle feeding device 6 and jacket sheath feeding device 7; said jig device 2 is a turntable type, installed in the middle of frame 1, said first knife handle feeding device 3, blade feeding device 4 , a pin assembly device 5 , a second handle loading device 6 and a sheath blanking device 7 are arranged around the jig device 2 in sequence.

[0024] The jig device 2 is used to accept the components to be assembled and realize their transfer; the first knife handle feeding device 3 and the second knife handle feeding device 6 are used to combine the blades on both sides of the blade The knife handle is loaded and assembled, the blade feeding device 4 is used to realize the loading and assembly of the blade, and the pin shaft assembly device 5 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com