Auxiliary fixing device for electric permanent-magnet workbench

A fixing device and electro-permanent magnet technology, which is applied in the field of mechanical processing, can solve the problems of damaging the electro-permanent magnet table, and achieve the effects of easy cleaning, avoiding damage, and avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

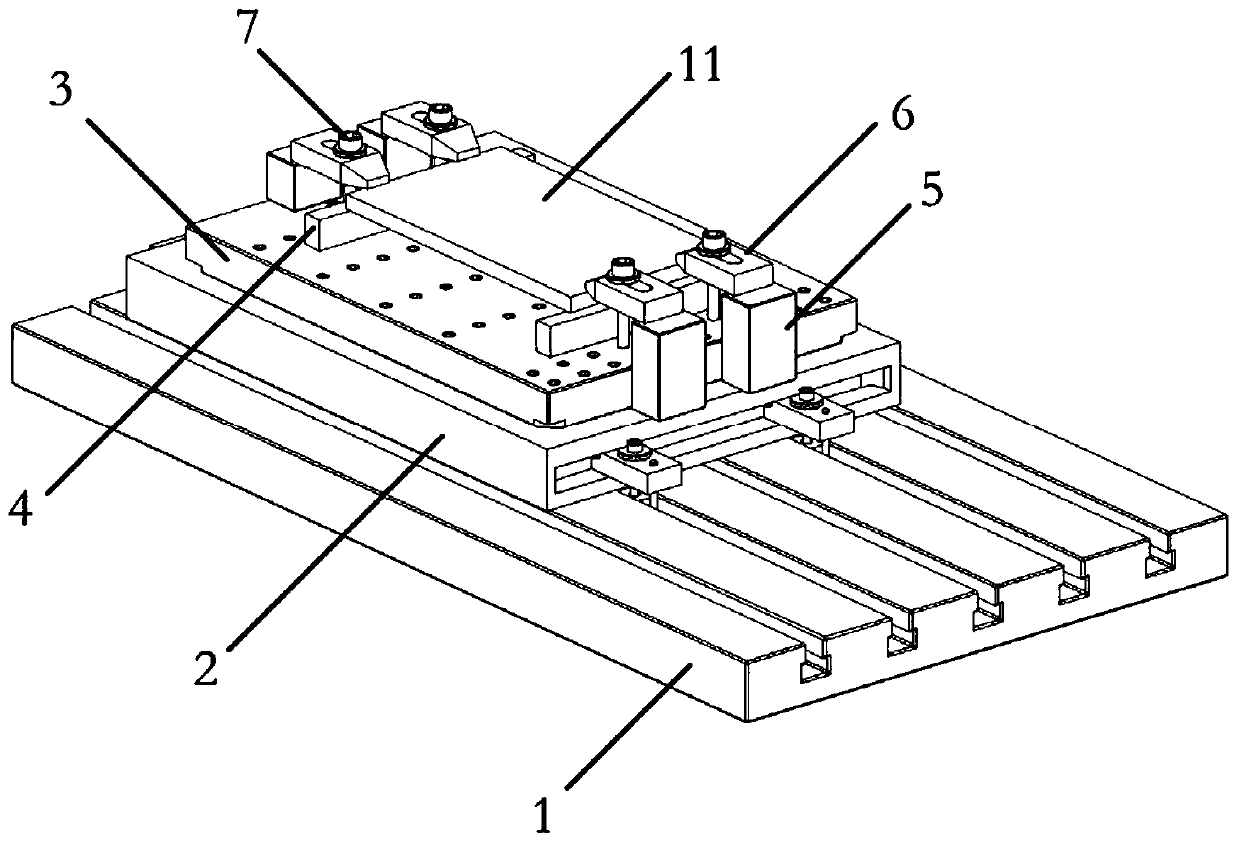

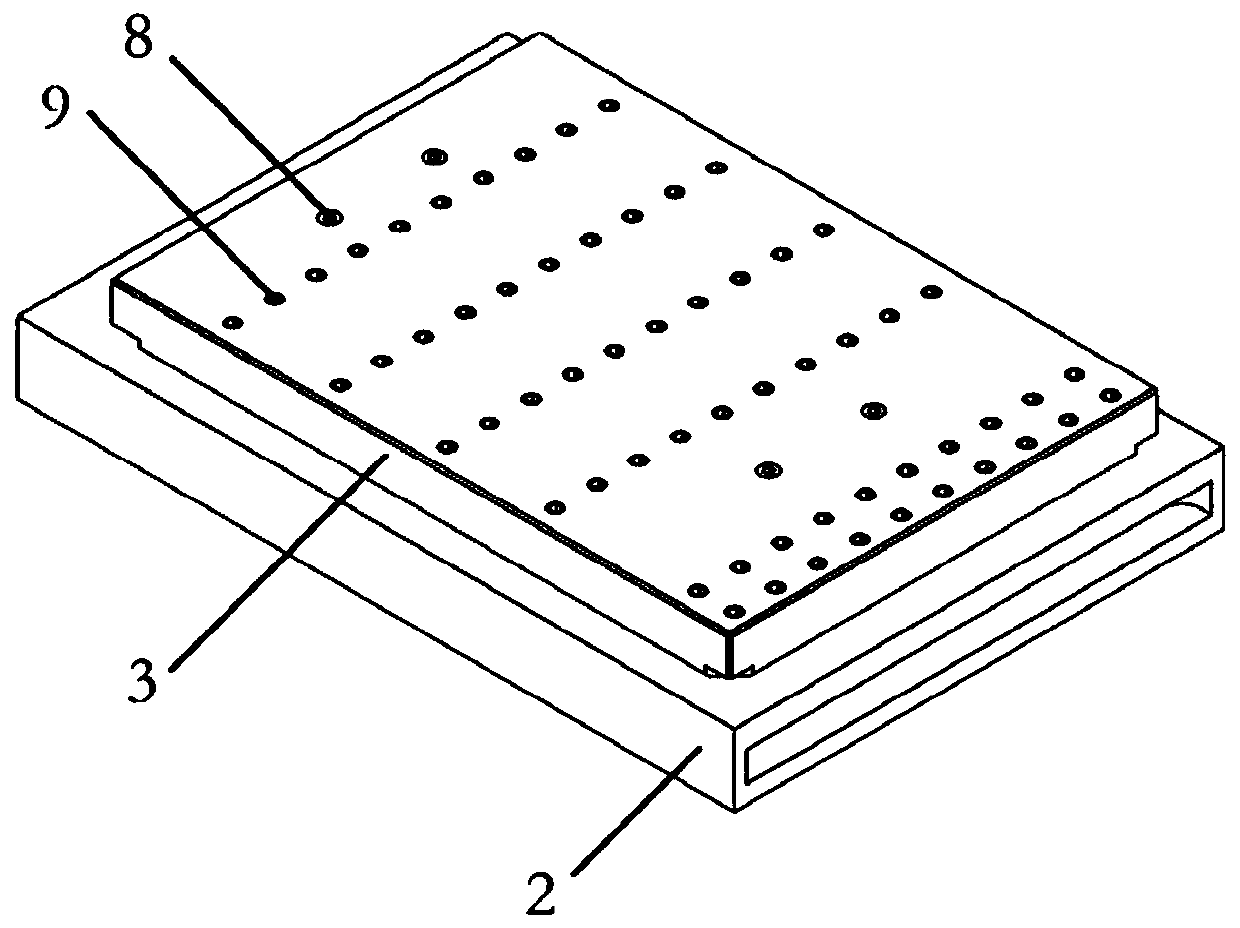

[0033] Such as figure 1 -5 shows a specific implementation of the electric permanent magnet table auxiliary fixing device provided in this embodiment, including: a protective case 3 and a pair of clamping assemblies.

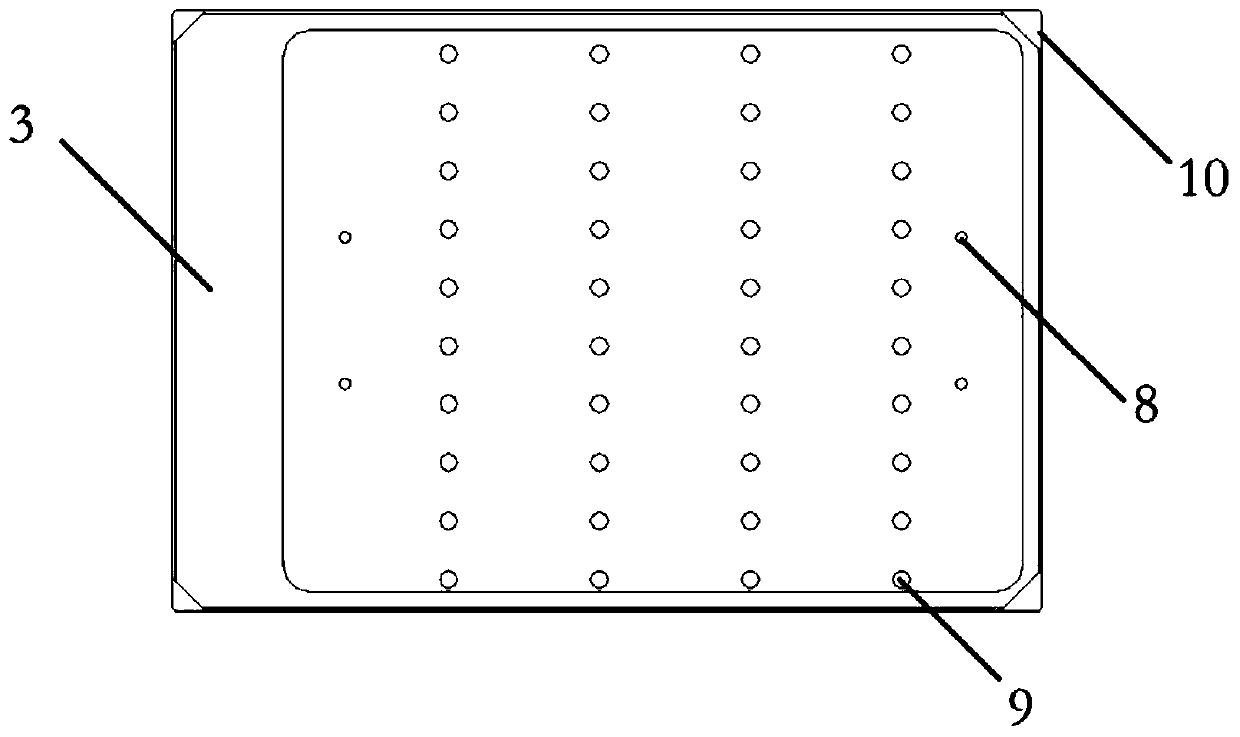

[0034] The bottom surface of the protective shell 3 is provided with a cavity groove, and the protective shell 3 is fixed on the top of the electro-permanent magnetic table 2 through the cavity groove. The top surface of the protective shell 3 is provided with a plurality of first through holes 9, and the plurality of first The through holes 9 are arranged in rows and columns, and the first through holes 9 are threaded holes. The opposite ends of the top surface of the protective case 3 are respectively provided with two second through holes 8, and the four second through holes 8 are respectively fixedly connected with the electro-permanent magnet table 2 by four fixing bolts as the second fasteners. , the fixing bolt is screwed into the threaded hole on the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com