Connecting seat for side beam and cross beam of railway rapid freight car bogie

A technology for connecting seats and bogies, which is applied to bogies, railway car body parts, transportation and packaging, etc., can solve the problems of high stress in welding parts and difficulty in meeting the assessment requirements of new standards, and achieve better stress conditions and effective Facilitate welding penetration and reduce welding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0021] In conjunction with the accompanying drawings.

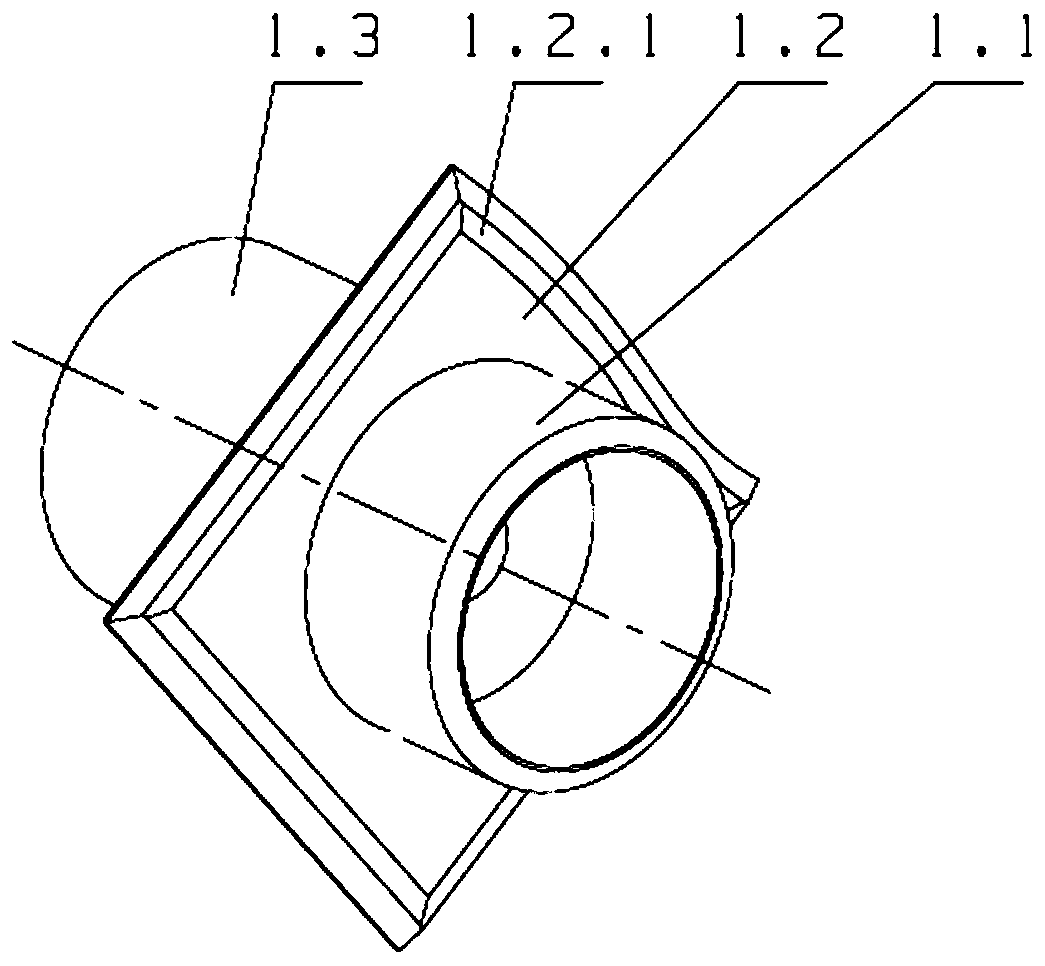

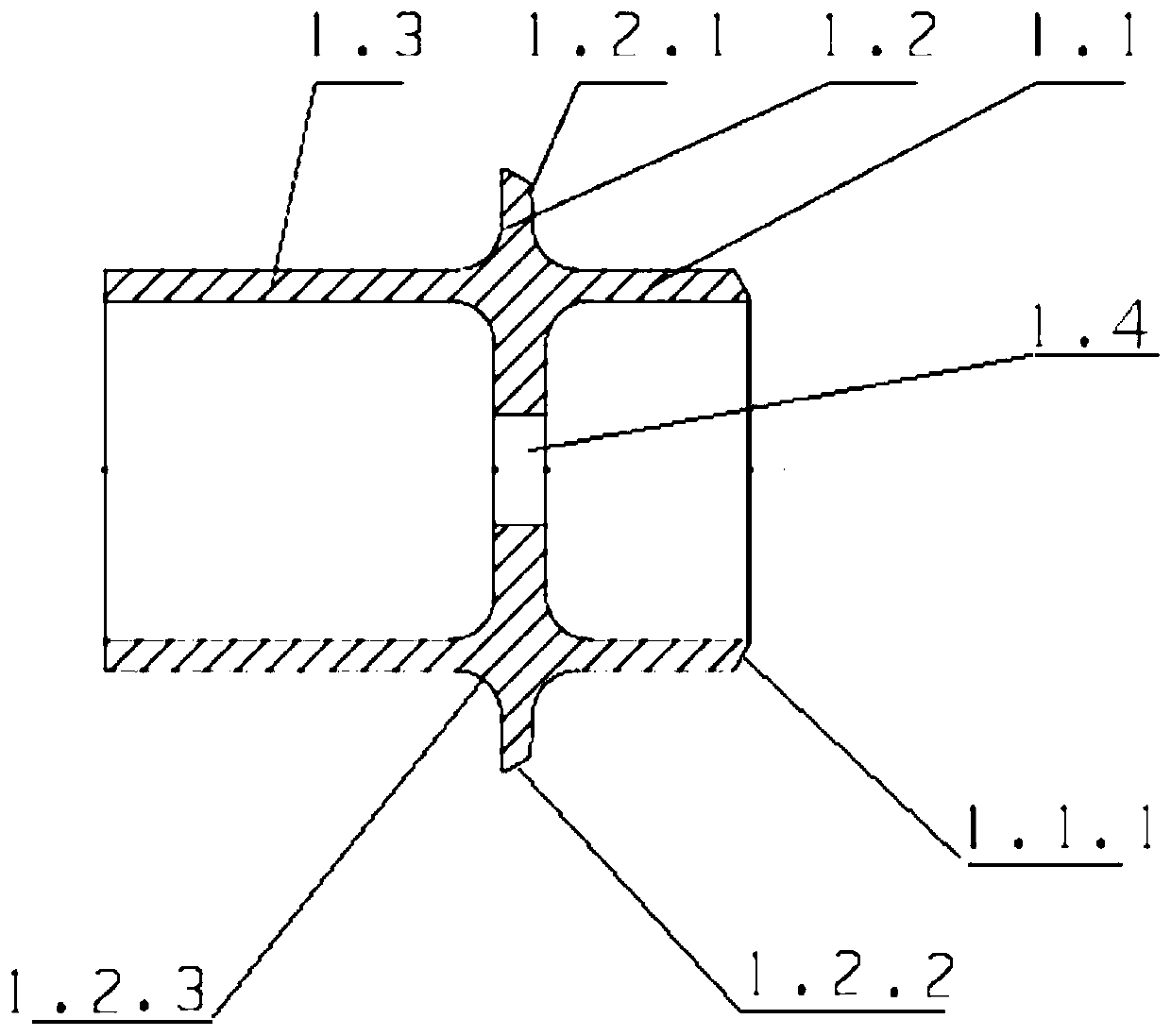

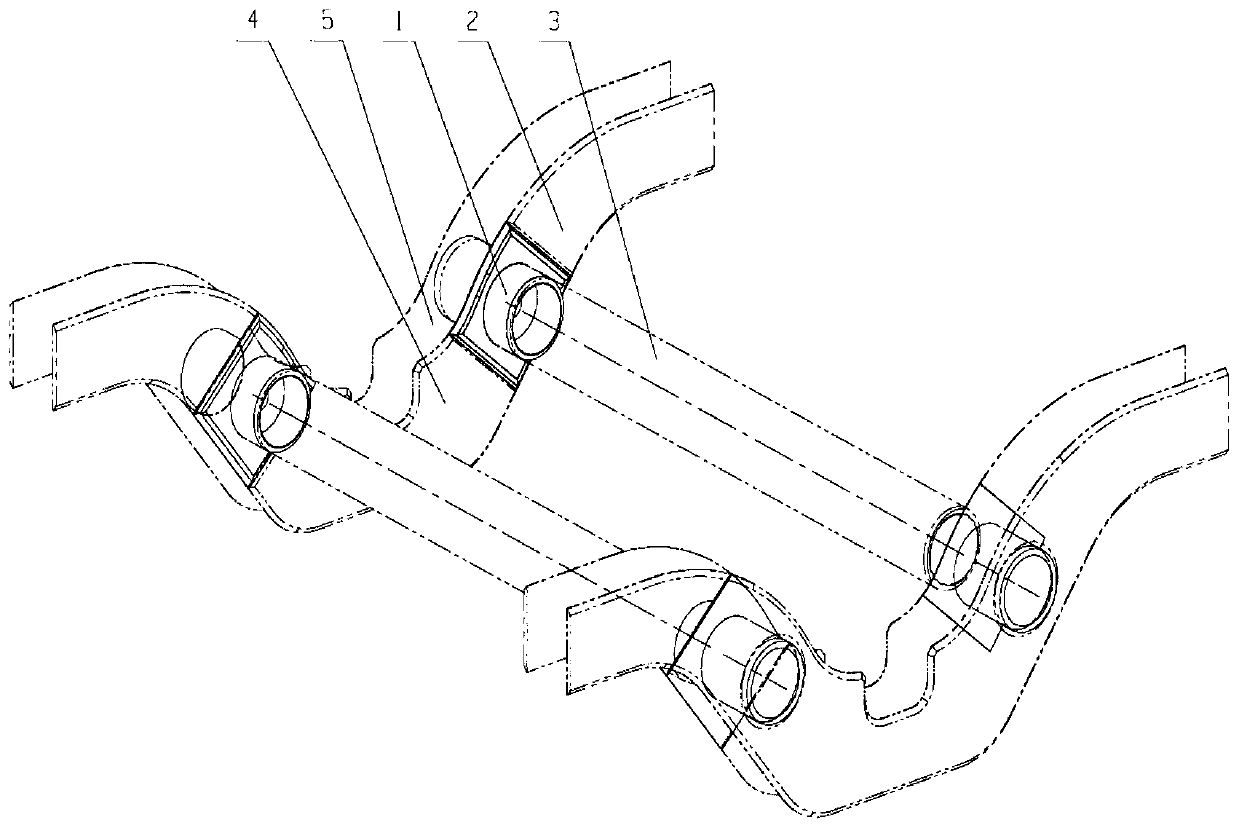

[0022] The connecting seat of the side crossbeam of the railway fast freight car bogie, the connecting seat 1 is composed of the inner cylinder part 1.1 connected with the crossbeam, the middle plate part 1.2 connected with the side beam inner belly end plate 2 and the side beam inner belly middle plate 4 and the outer part of the side beam The outer cylinder part 1.3 connected by the web 5 is formed, and the inner cylinder part 1.1 and the outer cylinder part 1.3 form a cylindrical structure and are connected by a middle plate part 1.2 of a planar stru...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap