Rapier loom for weft roving weaving and operation method thereof

A technology of rapier looms and weft yarns, which is applied in looms, textiles, textiles, and papermaking, and can solve the problems of increasing equipment costs, reducing costs, and disadvantages, and achieves the goals of improving work efficiency, reducing production costs, and improving fabric strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

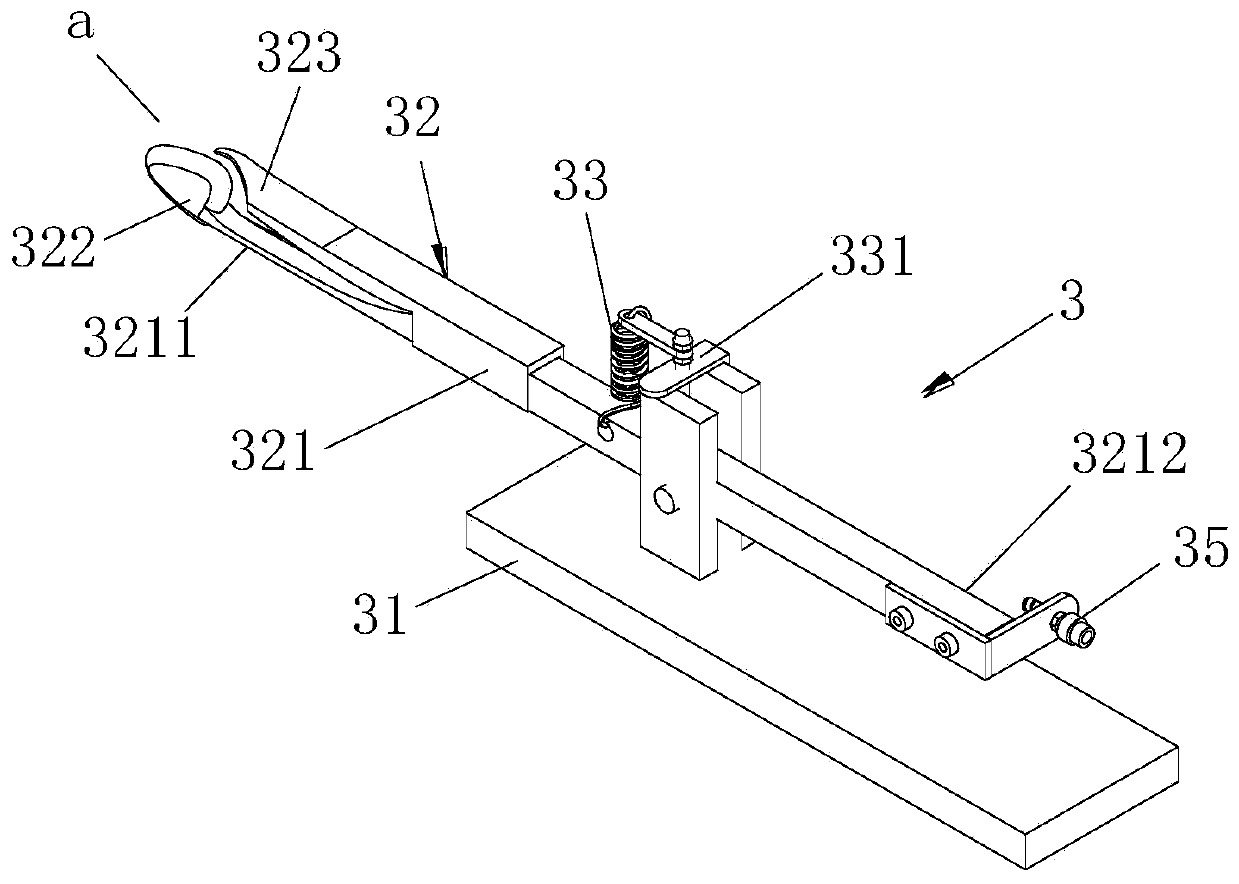

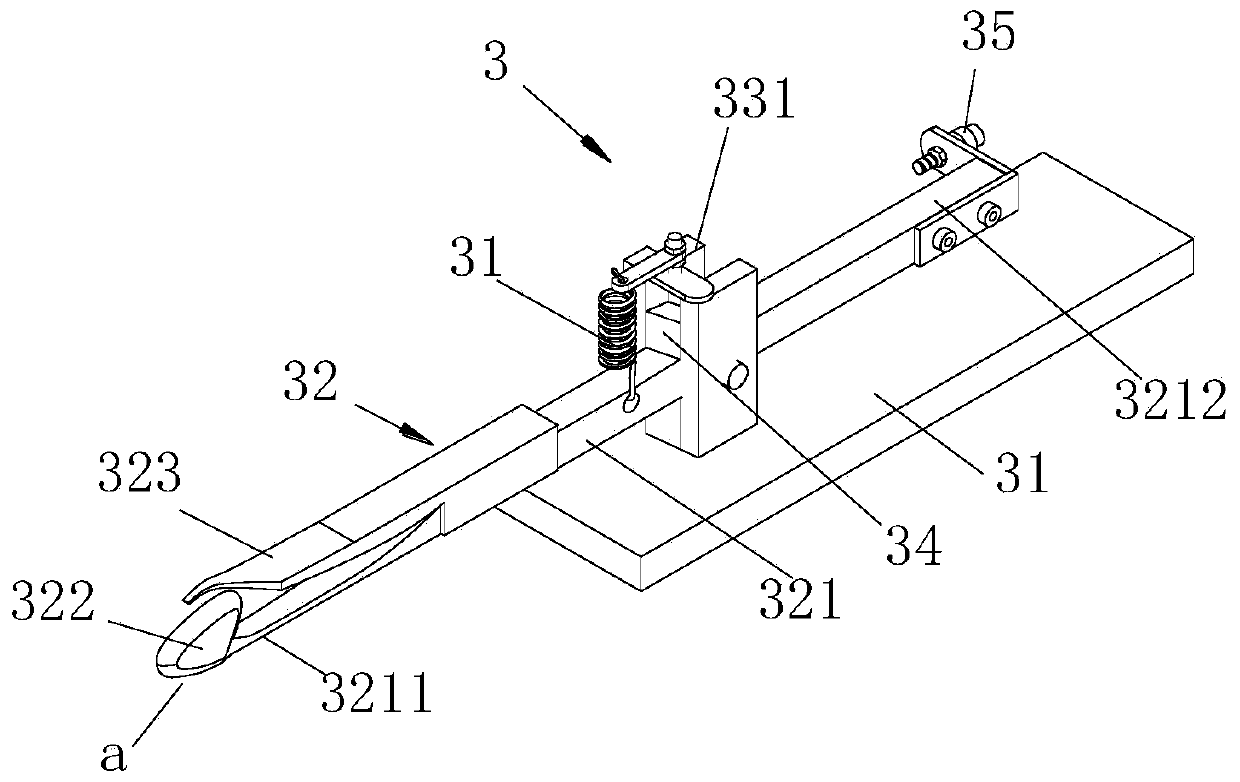

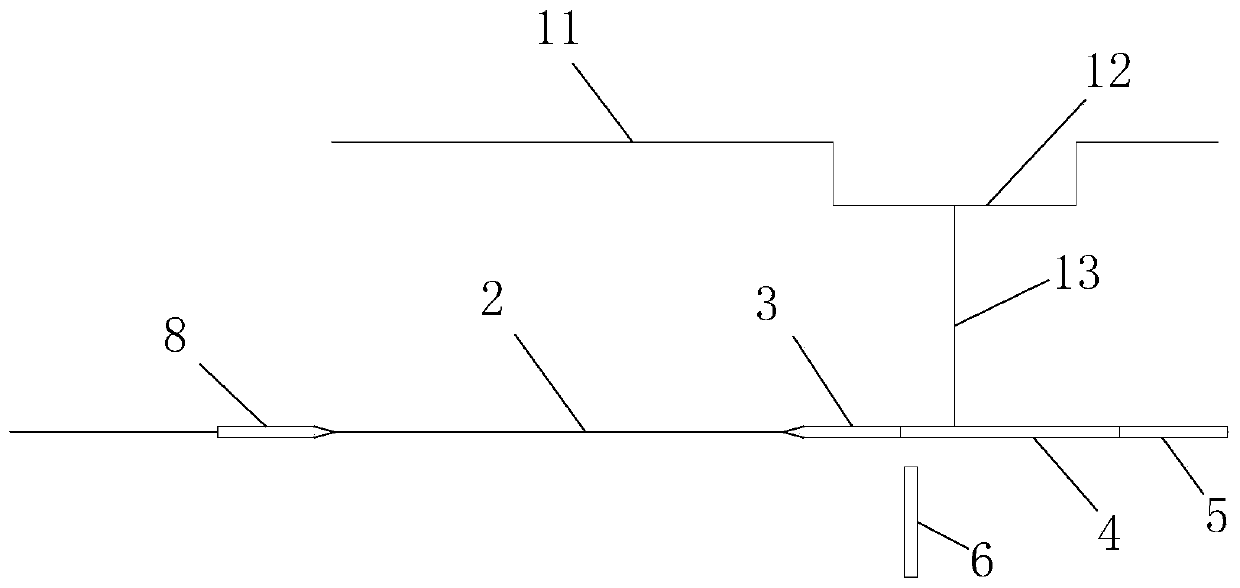

[0037] Embodiment one: if figure 1 , 2 , 3, and 4, the present embodiment includes a frame, and an opening mechanism installed on the frame, a weft insertion mechanism, a weft beating mechanism, a warp let-off mechanism and a coiling mechanism, and the weft insertion mechanism includes a weft feeding sword, which is installed on The weft feeding clip on the side of the weft sending sword, the weft sending and passing sword mechanism matched with the weft sending sword, the weft connecting sword matched with the weft sending sword, the weft receiving and passing sword mechanism matched with the weft connecting sword, the flexible Sword belt, sword wheel, guide device and sword opening mechanism. Wherein the frame is also equipped with a power source, the general power source is a motor, the output shaft of the motor is coaxially fixed with a main shaft 11, and a pendulum crank 12 is fixed on the main shaft 11; a pendulum 2 is hinged on the frame, Then latitude sword 3, flexib...

Embodiment 2

[0041] Embodiment 2: This embodiment is a method for operating a rapier loom, comprising the following steps:

[0042] Step 1, the warp is separated up and down by a shedding mechanism to form a shed;

[0043] Step 2, several weft yarns form a weft yarn bundle, which is fixed by the weft supply clamping member, and the weft feeding sword picks up the weft yarn bundle with the help of the weft feeding and passing sword mechanism, and carries the weft yarn bundle from one side of the shed to the other. side push;

[0044] Step 3, the weft receiving sword 3 moves toward the close weft sending sword 8 with the help of the weft receiving and passing sword mechanism 7, and completes the handover of the weft yarn bundle with the weft sending sword 8 at a position close to the other side of the shed. Beam exits from weft sending sword 8;

[0045] Step 4, when the weft-connecting sword 3 exits the shed with the weft bundle, the beating mechanism pushes the weft bundle introduced into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com