Automatic pressing, upturning, opening and closing structure for furniture

A furniture and automatic technology, applied in the direction of switches with braking devices, building components, wing leaf openers, etc., can solve the problems of unable to achieve automatic opening and closing, unable to achieve uniform effect, unable to meet the needs of use, etc., to achieve improved Use experience, smooth opening and closing process of flipping, and small collision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

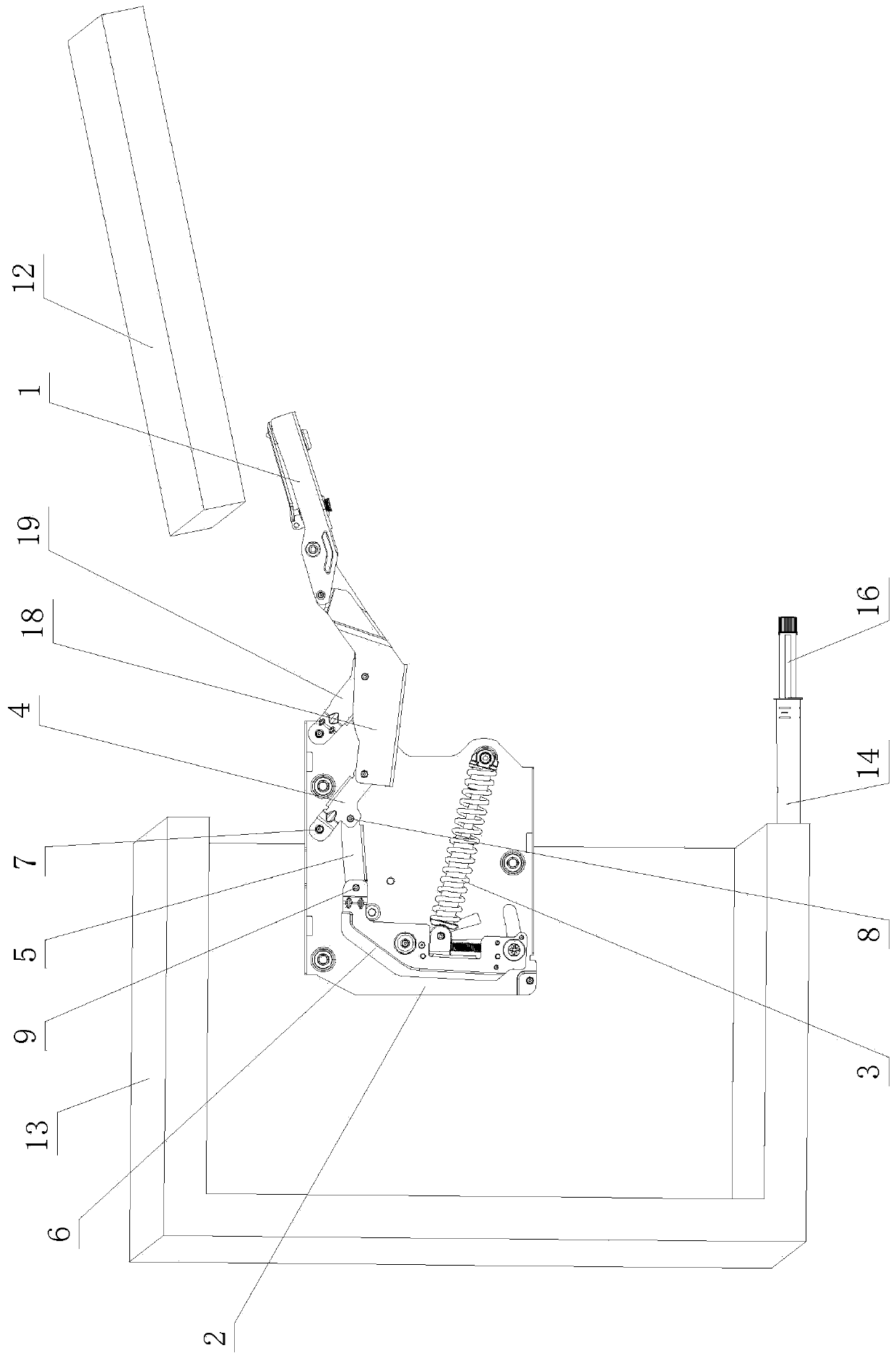

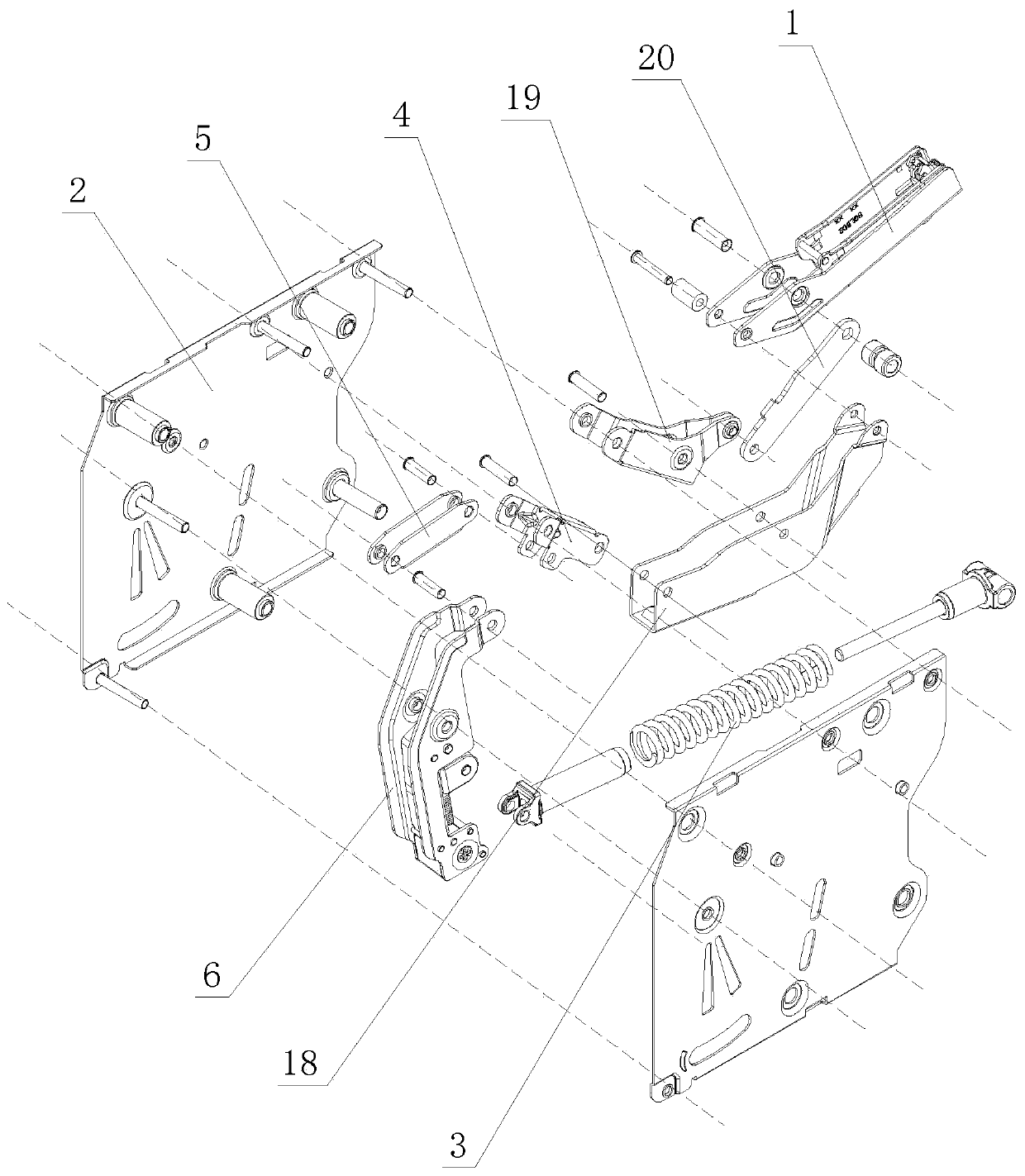

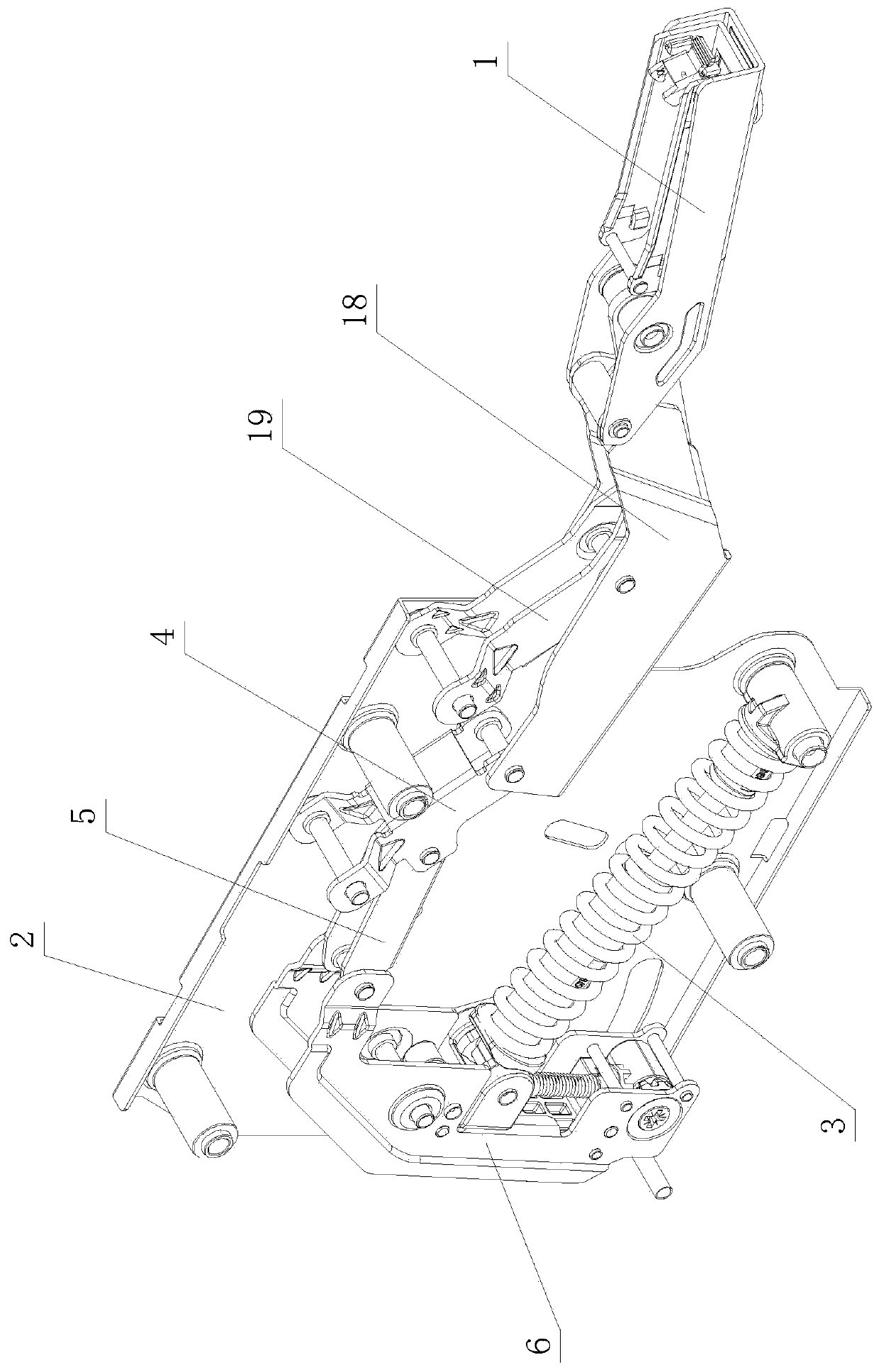

[0033] see Figure 1-Figure 7 , the furniture uses an automatic push-up opening and closing structure, including a push element 1, a fixing element 2, a connecting arm assembly, and an elastic member 3. The connecting arm assembly includes at least a first connecting arm 4, a second connecting arm 5, and a third connecting arm 6. The first connecting arm 4 is hinged on the fixed element 2, and is hinged with the pushing element 1 and one end of the second connecting arm 5 respectively; the third connecting arm 6 is hinged on the fixed element 2, and is hinged with the other end of the second connecting arm 5 Hinged, the elastic member 3 elastically acts on the third connecting arm 6; the said pushing member 1 is opened and closed on the fixed member 2 through the joint elastic hinge of the connecting arm assembly and the elastic member 3 .

[0034] When the push element 1 is hinged to a certain position relative to the fixed element 2 at the open terminal position, the elastic...

no. 2 example

[0051] see Figure 8 , the furniture uses an automatic push-up opening and closing structure, which is different from the first embodiment in that: the fixing part 15 is provided with a fixing part, and is fixedly arranged on the furniture cabinet body 12 through the fixing part.

[0052] Other unmentioned parts are the same as the first embodiment.

no. 3 example

[0054] see Figure 9 , This furniture uses an automatic push-up opening and closing structure, which is different from the first embodiment in that: a fixing part is provided between the fixing part 15 and the fixing element 2, and the two are fixed to each other through the fixing part.

[0055] Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com