Automatic ash discharge system

A fully automatic, fire exhaust technology, applied in the field of combustion furnaces, which can solve problems such as hazards and poor continuous fuel supply capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

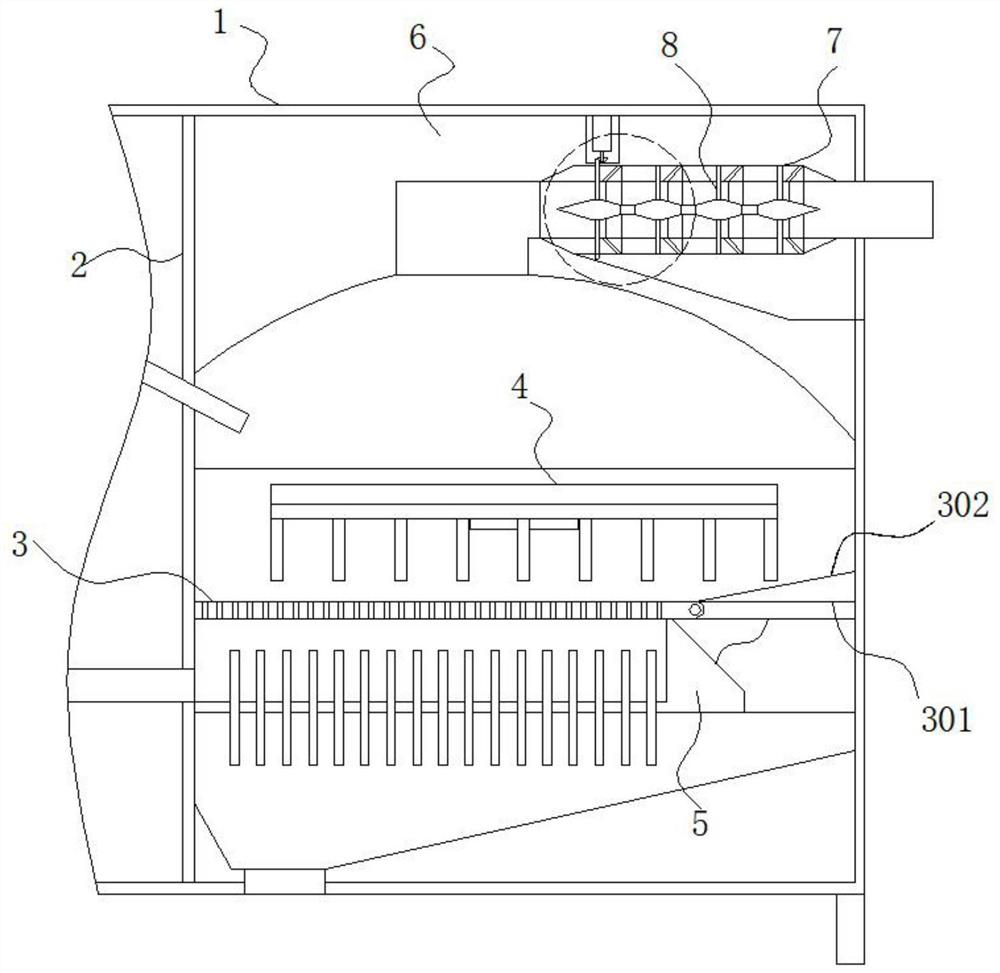

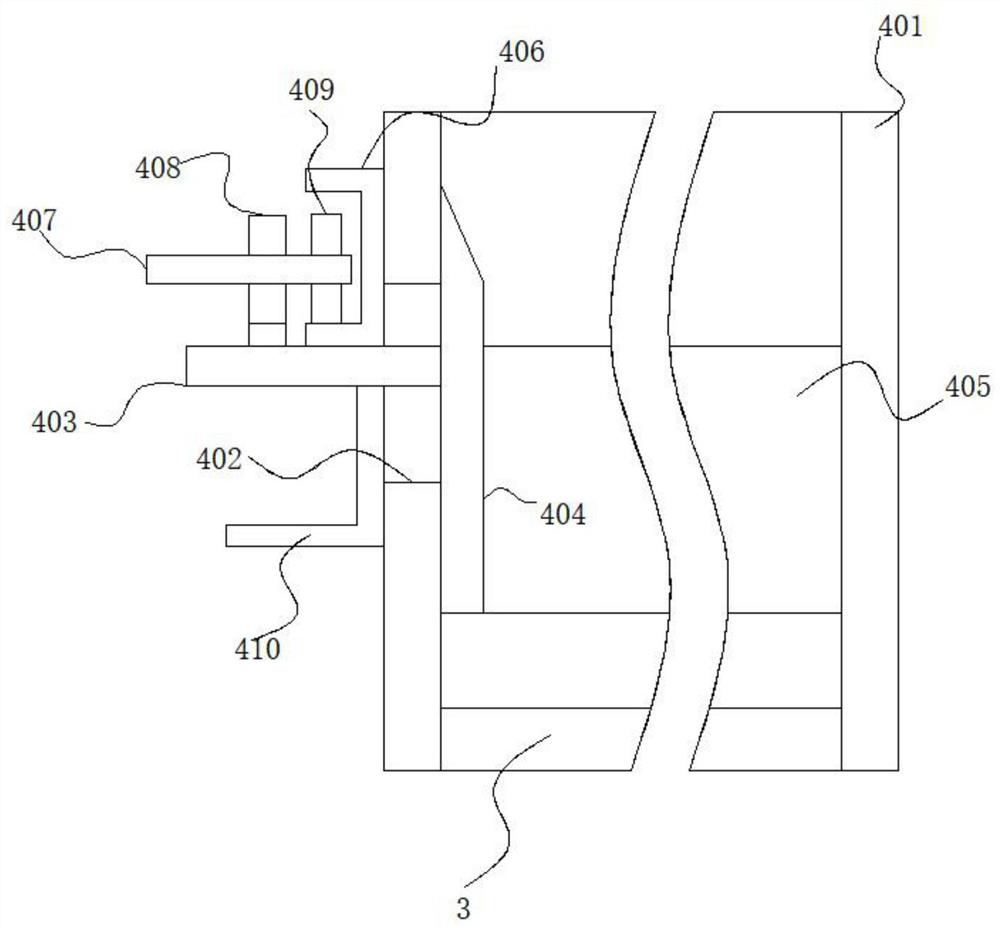

[0033] One end of the air intake box 5 near the dividing plate 2 is equipped with an intake pipe fixedly socketed with the dividing plate 2, the top of the air intake box 5 is provided with a vent hole running through the combustion plate 3, and the bottom of the air intake box 5 is fixedly sleeved with a The heat conducting rods arranged equidistantly in the length direction, and the heat conducting rods stretch out from the bottom of the air intake box 5, the bottom of the movable plate 301 is equipped with a guide plate positioned at the bottom of the combustion furnace 1 and inclined, and the guide plate extends to the air intake box 5 Below the bottom of the combustion plate 3, a feed pipe inclined downwards is installed above the side of the combustion plate 3 close to the partition plate 2;

Embodiment 2

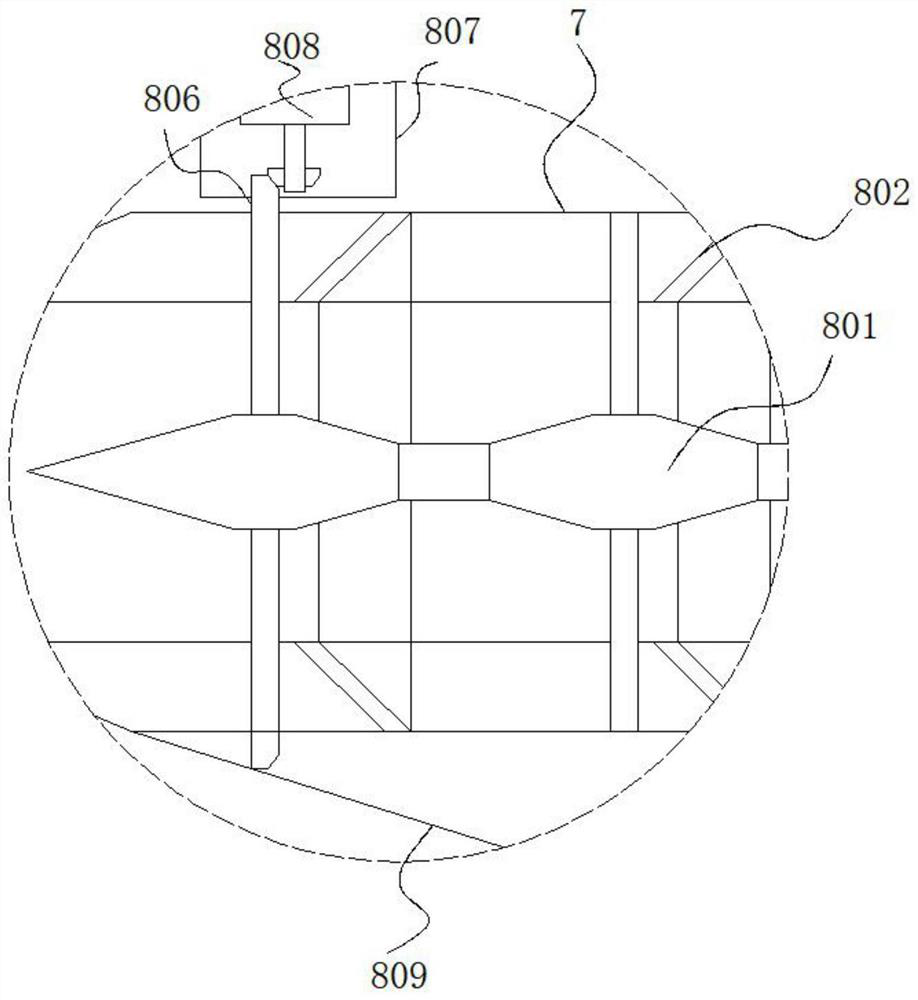

[0035] The driving mechanism 808 includes a gear with the inner core of the gear ring. The inner ring of the gear is fixedly sleeved with a rotating shaft. One end of the rotating shaft is installed with a third motor fixedly connected to the inner wall of the installation groove 807 through a coupling. The adsorption collar 802 is far away from the fire exhaust. The surface of the discharge end of channel 7 is provided with adsorption grooves of annular structure distributed along its diameter direction, and the cleaning device is attached to the adsorption grooves. The cross section of the adsorption grooves is an isosceles triangle structure.

[0036] Working principle: when in use, the fuel in the feed pipe enters the top of the combustion plate 3 downwards, and then the first motor connected to the rotating shaft 407 on the push assembly 4 is started, and the rotation 407 drives the push gear 409 and the extrusion wheel 408 at this time Rotate at the same time, when the sque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com