Wave-driven ship

A wave and wave energy technology, applied in ship construction, ship propulsion, ship components, etc., can solve the problems of discontinuous energy conversion, large installation size, and large energy loss, and achieve the effect of improving transmission efficiency and reducing installation size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The object of the present invention is to provide a transmission mechanism that drives the ship to sail by sea waves, so as to realize the ship's sailing under emergency sea conditions. In order to achieve the above object, the present invention includes four aspects: a hull, a wave energy capture device installed with the hull, a mechanical energy conversion device, and a mechanical energy output device. The hull provides the installation space for the entire device, serving as the carrier and the final power output object of the entire system. The wave energy capture device collects the vertical wave potential energy and converts it into mechanical energy in the form of bidirectional rotation. The mechanical energy conversion device converts the bidirectional rotational mechanical energy of the capture device into unidirectional continuous rotational mechanical energy and transmits it to the output device for the ship to drive. The innovations of the present invention...

Embodiment 2

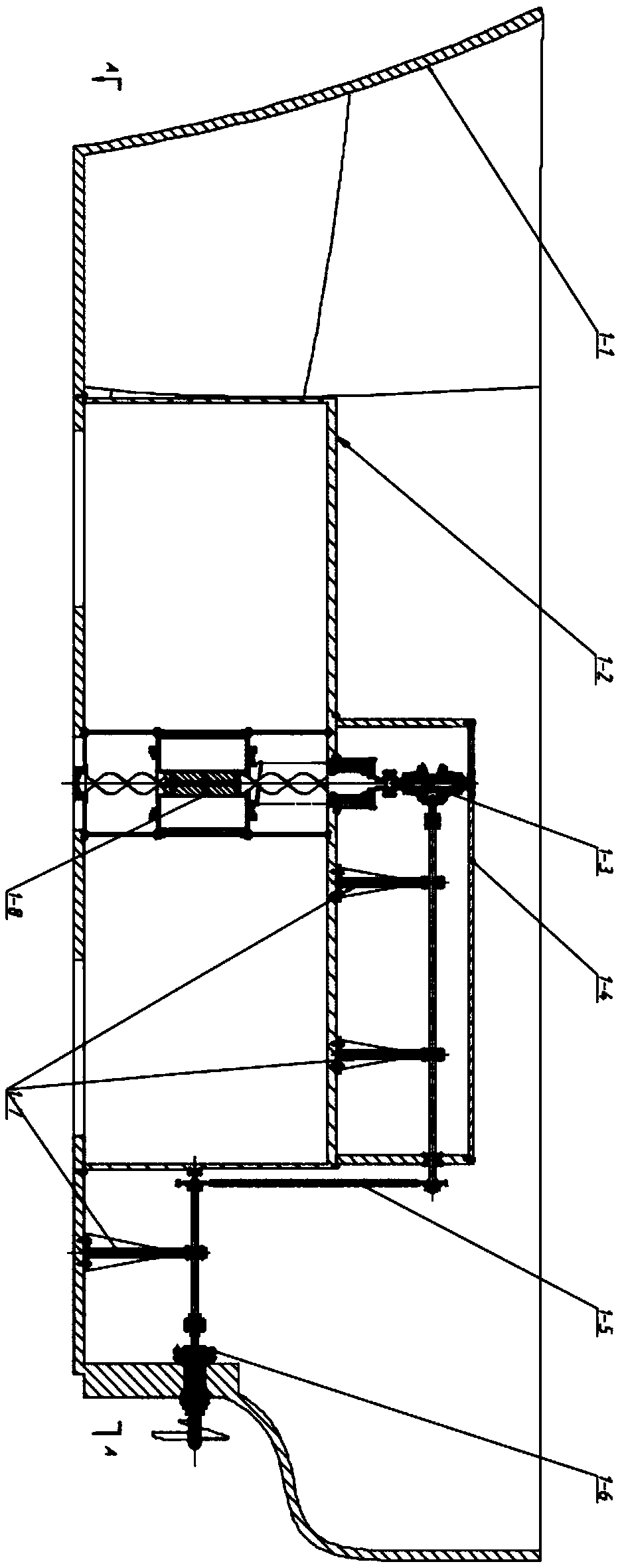

[0018] figure 1 : Overall scheme of wave-driven ship and transmission device. The overall plan includes: hull 1-1, water tank 1-2, mechanical energy conversion device 1-3 (see Figure 4 ), upper installation storehouse 1-4, chain drive 1-5, mechanical energy output device 1-6, shaft bearing mounting bracket 1-7, wave energy capture device 1-8. The A-A sectional view is taken from the bottom of the ship.

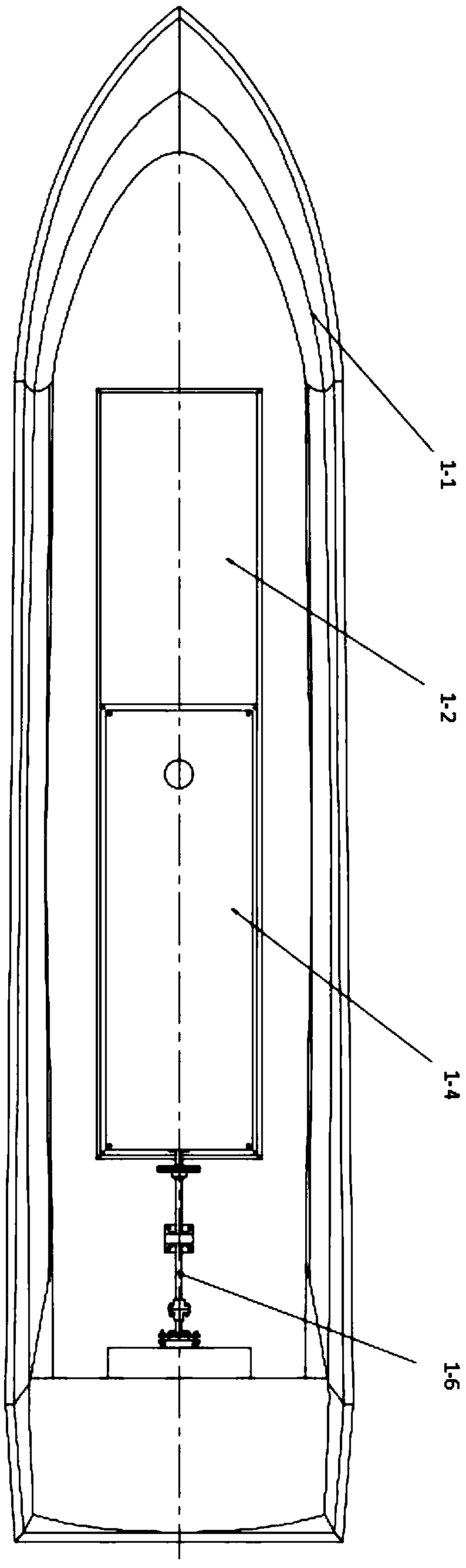

[0019] figure 2 Top view of wave-driven boat and transmission. The top view includes: a hull 1-1, a water tank 1-2, an upper installation tank 1-4, and a mechanical energy output device 1-6. It can be seen from the top view that the whole device is symmetrically installed on the left and right sides of the hull.

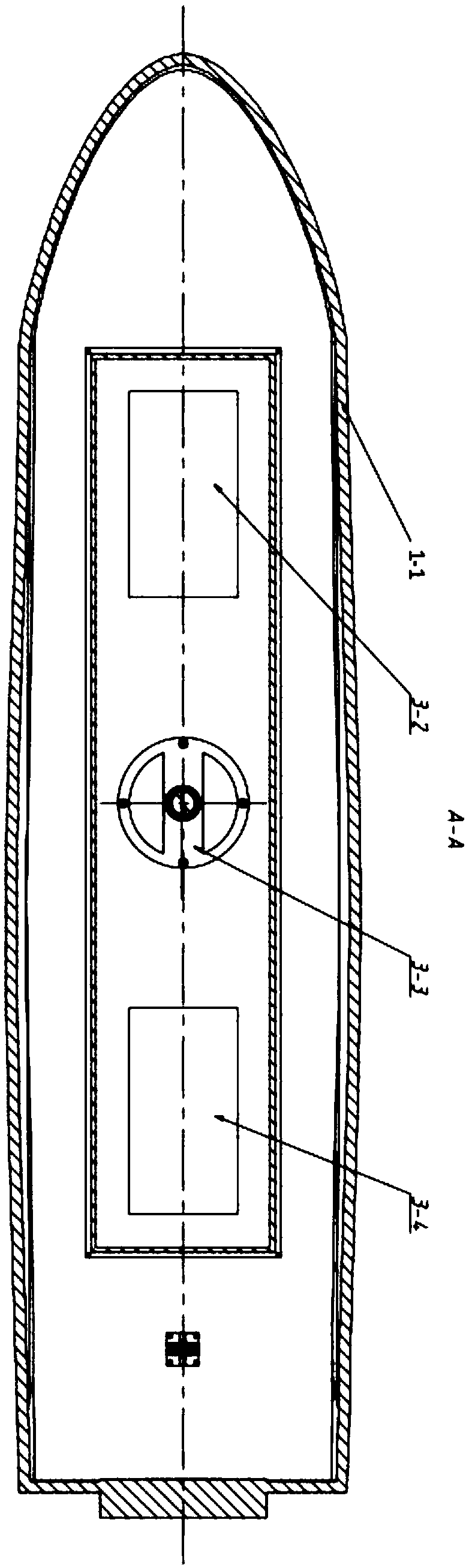

[0020] image 3 A-A sectional view of wave-driven ship and transmission device. A-A sectional view includes: a hull 1-1, a first water inlet 3-2 at the bottom of the ship, an underframe 3-3 for installing a capture device, and a second water inlet 3-4 at the...

Embodiment 3

[0025] Combine below figure 1 , 2 , 3, 4, and 5 illustrate specific embodiments of the present invention. The following definition of the direction of rotation is as follows: clockwise rotation viewed from the bottom of the hull is forward rotation, and clockwise rotation viewed from the stern to the bow is forward rotation.

[0026] Since floats of different shapes can capture unused wave energy under the same effective displacement volume, the vertical cylindrical float with higher energy capture efficiency is selected as the float type selection. Long cuboid helical drive nut 4-14 installation space.

[0027]The screw rods 4-8 are single-helix shaftless screw rods, the cross section of which is a chamfered rectangle, and its structure is formed by rotating and scanning the chamfered rectangle along the axial direction. The inner drive surface of the screw drive nut 4-14 is engaged with the outer surface of the screw rod 4-8, and a lubricating gap of 0.1 mm is reserved in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com