Optical structure of LCD projector, projector and P light and S light conversion method

An optical structure and projector technology, applied in optics, instruments, projection devices, etc., can solve problems such as low light efficiency, low uniformity, and light clutter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

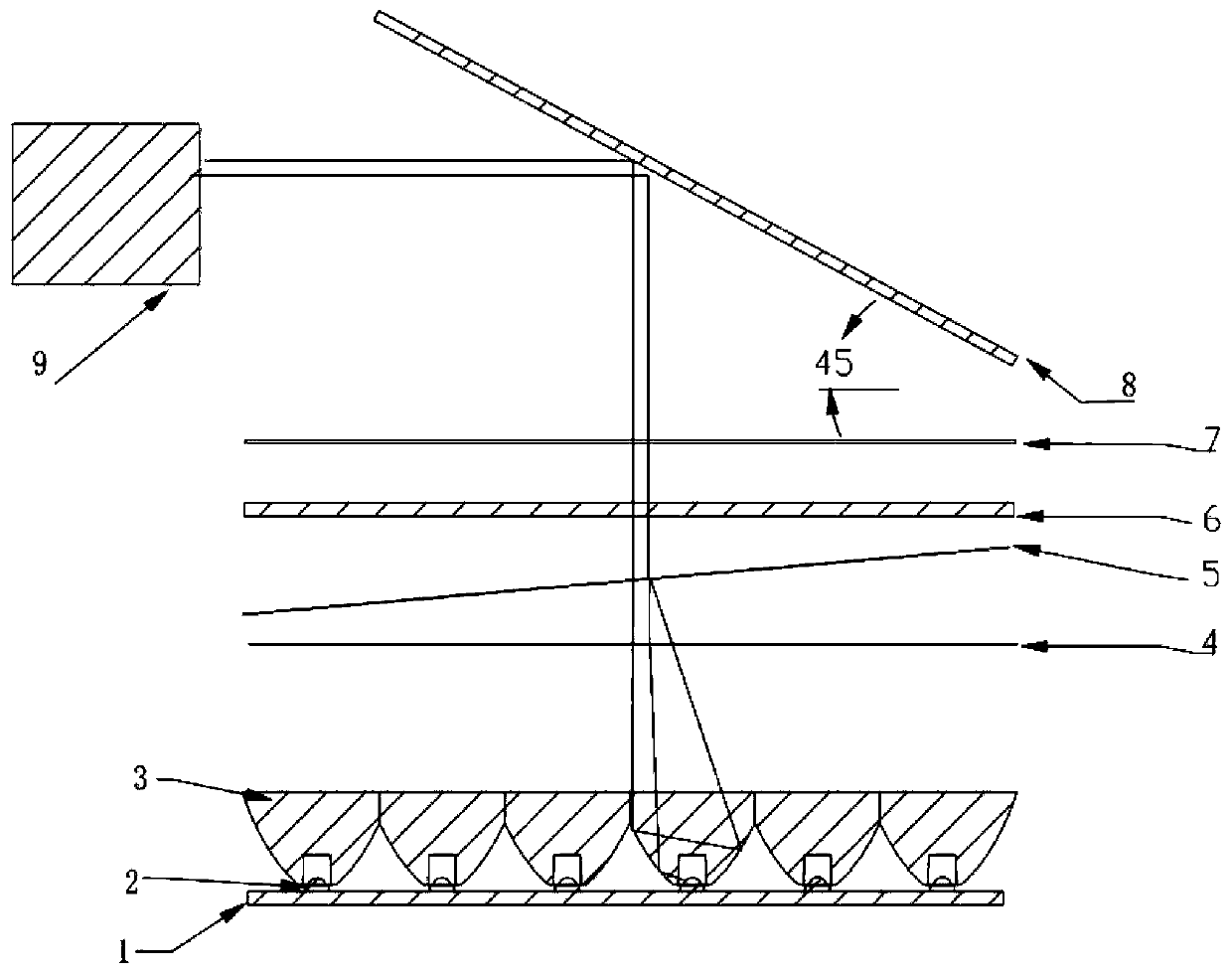

[0033] like figure 1 Shown: the technical problem to be solved in the present invention is to provide a kind of novel LCD projector optical structure, this structure is by LED array 1, with one-to-one corresponding primary lens 2 array and secondary lens 3 array, 1 / 4 wave plate 4. Reflective polarizer 5, liquid crystal screen 6, Fresnel lens 7, mirror 8 and lens 9 are composed, and the above components are arranged in sequence. Among them, the primary lens adopts a convex lens, and the secondary lens adopts a lamp cup type collimating and uniform light lens. The included angle between its Fresnel lens 7 and the mirror 8 is 45°. The secondary lens 3 array, the 1 / 4 wave plate 4, the liquid crystal screen 6, and the Fresnel lens 7 are parallel, and the lens 9 and the liquid crystal screen 6 are vertical.

[0034] Reflective polarizer 5 described in the present embodiment is not parallel to liquid crystal screen 6 and 1 / 4 wave plate 4, but has a small angle, as figure 1 shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com