Light plasma tube pressure sealing system and pressure sealing method

A plasma tube and tube clamping technology, which is applied in the direction of electric tube/light off, etc., can solve the problems of difficult to guarantee product consistency and slow production efficiency, and achieve the effect of improving production efficiency, improving work efficiency and ensuring consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

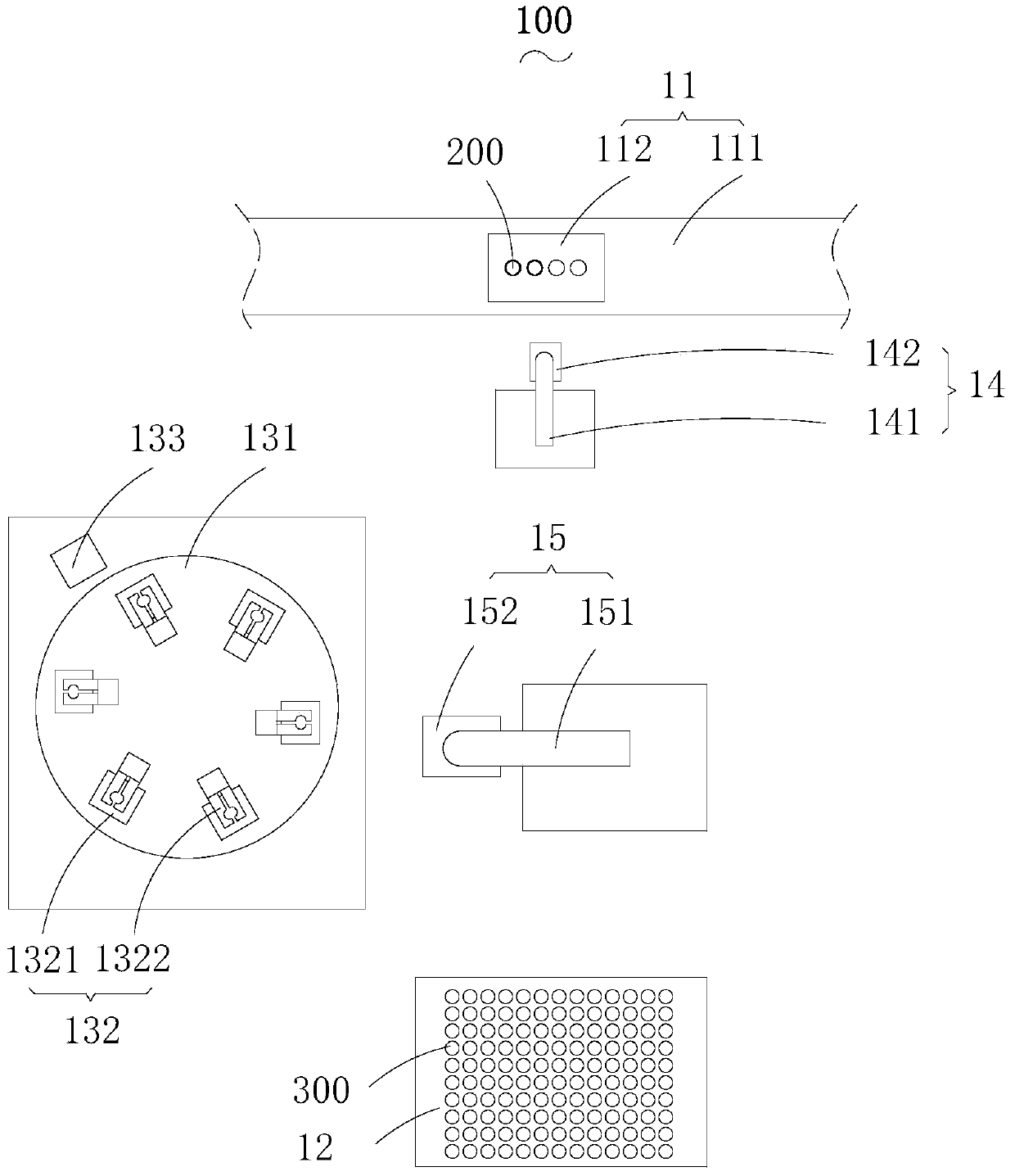

[0045] Such as Figure 1-4 As shown, the optical plasma tube sealing system 100 provided by the embodiment of the present invention is used to seal the electrode 300 at the end of the glass tube 200, including the glass tube transmission mechanism 11, the electrode placement frame 12, the sealing device, the first clamping device 14 and a second clamping device 15, wherein,

[0046] The glass tube delivery mechanism 11 is used to deliver the glass tube 200 , and includes a clamping tool 111 and a conveyor belt 112 for delivering the clamping tool 111 . The glass tube 200 is clamped and fixed on the tube clamping tool 111 . The clamping tool 111 not only has a place for placing the glass tube 200, but also has a place for placing semi-finished products.

[0047] The electrode placement rack 12 is arranged on one side of the glass tube conveying mechanism 11 for placing the electrodes 300 to be installed, and the electrodes 300 are placed on the electrode placement rack 12 in r...

Embodiment 2

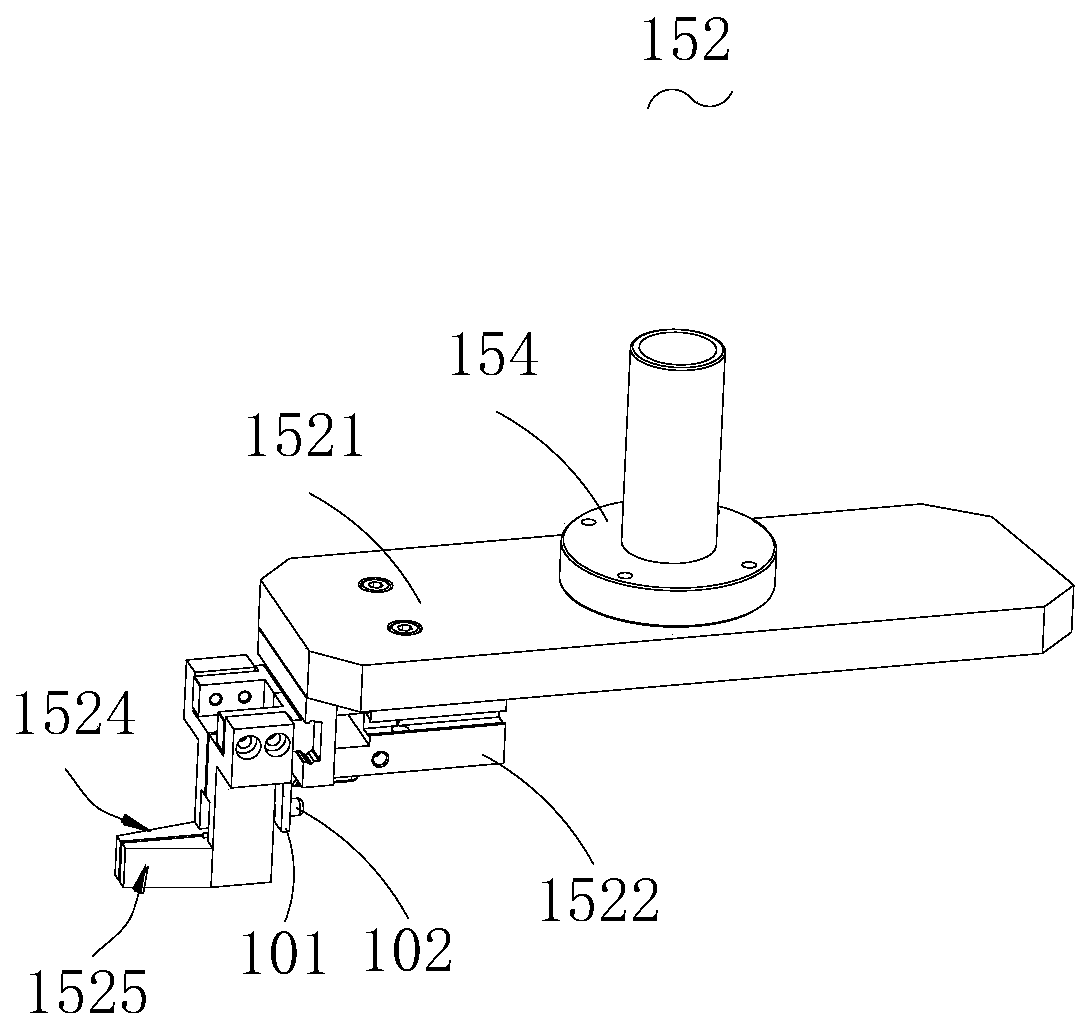

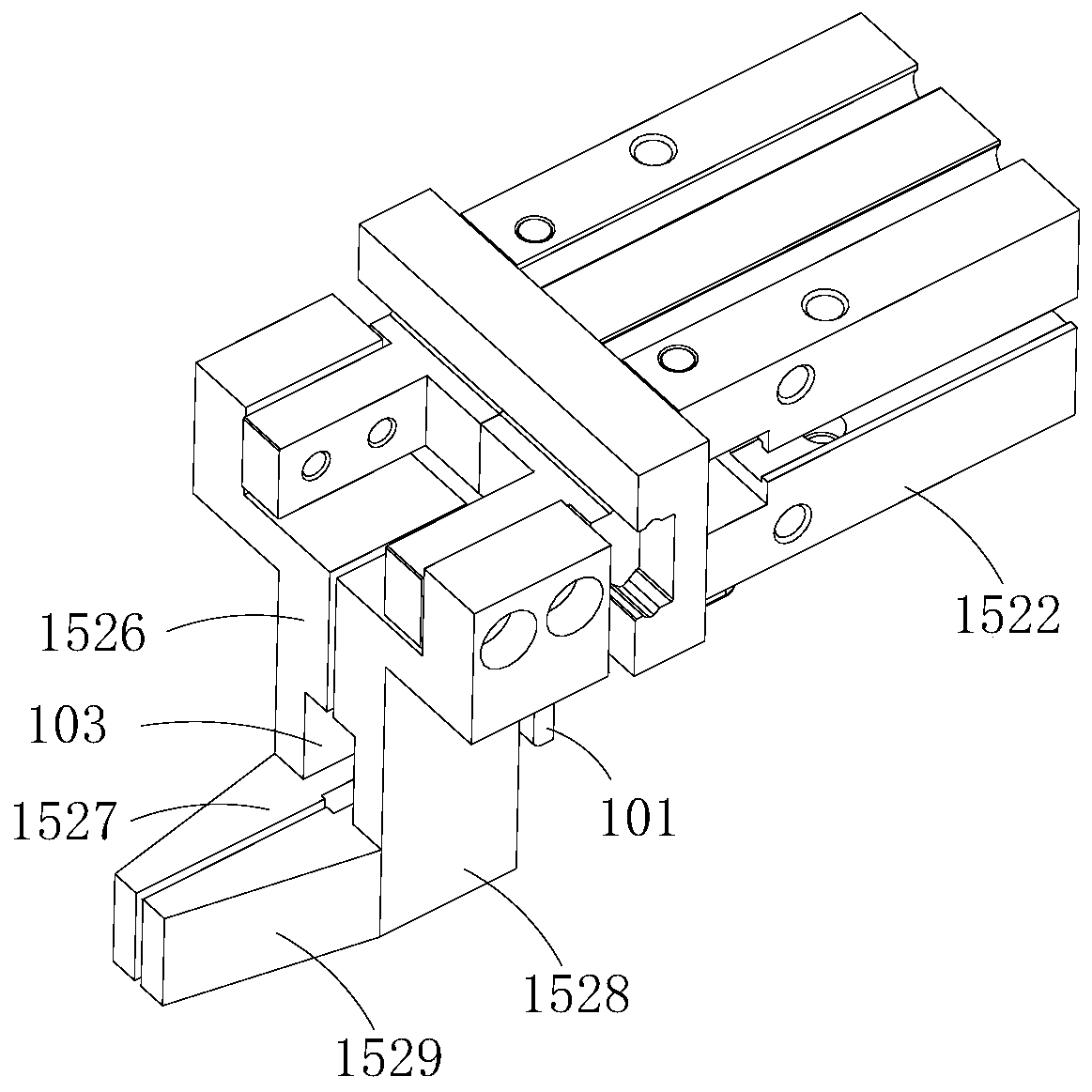

[0069] Such as Figure 3-Figure 7 As shown, the optical plasma tube sealing system 100 provided by the embodiment of the present invention is used to seal the electrode 300 at the end of the glass tube 200, including the glass tube transmission mechanism 11, the electrode placement frame 12, the sealing device, the first clamping device 14 and a second clamping device 15, wherein,

[0070] The glass tube delivery mechanism 11 is used to deliver the glass tube 200 , and includes a clamping tool 111 and a conveyor belt 112 for delivering the clamping tool 111 . The glass tube 200 is clamped and fixed on the tube clamping tool 111 . The clamping tool 111 not only has a place for placing the glass tube 200, but also has a place for placing semi-finished products.

[0071] The electrode placement rack 12 is arranged on one side of the glass tube conveying mechanism 11 for placing the electrodes 300 to be installed, and the electrodes 300 are placed on the electrode placement rack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com