Wafer film thickness detection method and edge washing boundary detection method

A detection method and layer thickness technology, which can be used in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., to solve the problems of delayed detection results, inability to obtain the thickness of wafer film layers, etc., to achieve easy access and easy edge cleaning Boundary, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object and features of the present invention more obvious and easy to understand, the technical solutions of the wafer film layer thickness detection method and the edge cleaning boundary detection method proposed by the present invention will be described in detail below in conjunction with the accompanying drawings. The present invention can be realized in different forms , should not be limited to the described embodiments. In addition, it should be noted that all the drawings are in a very simplified form and use inaccurate scales, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

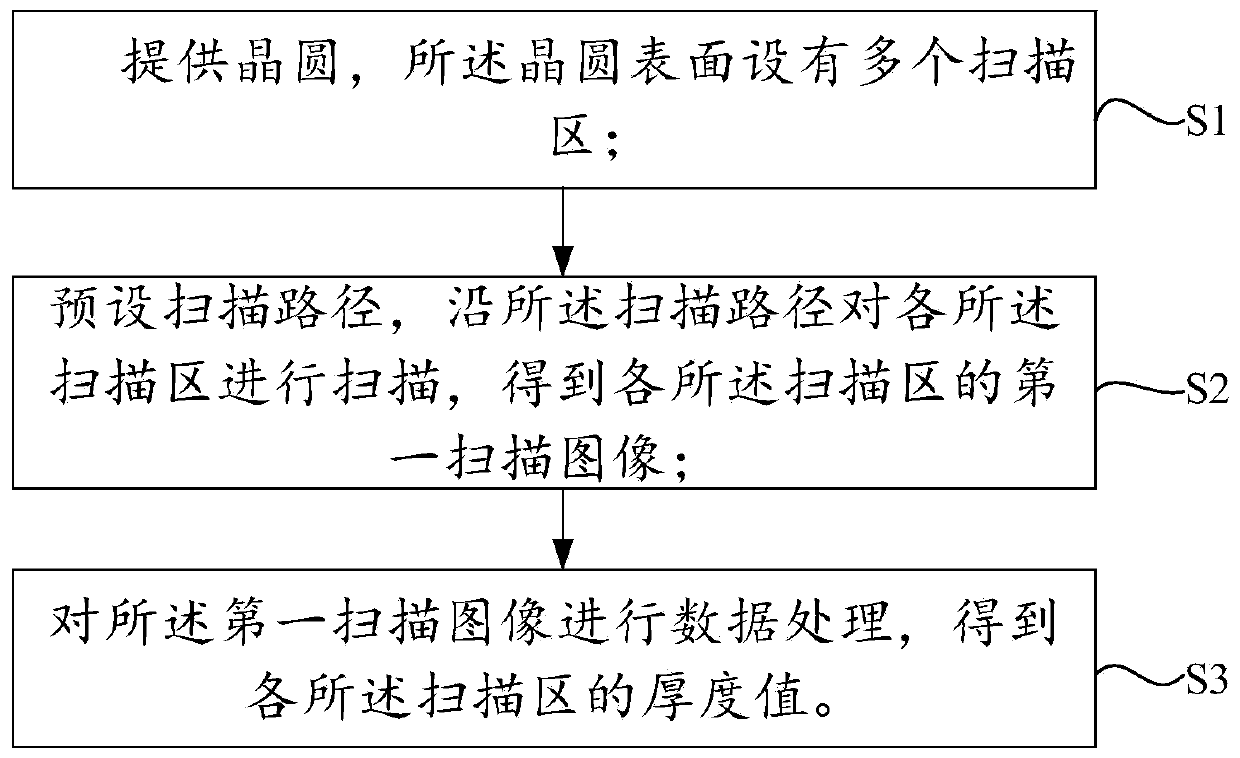

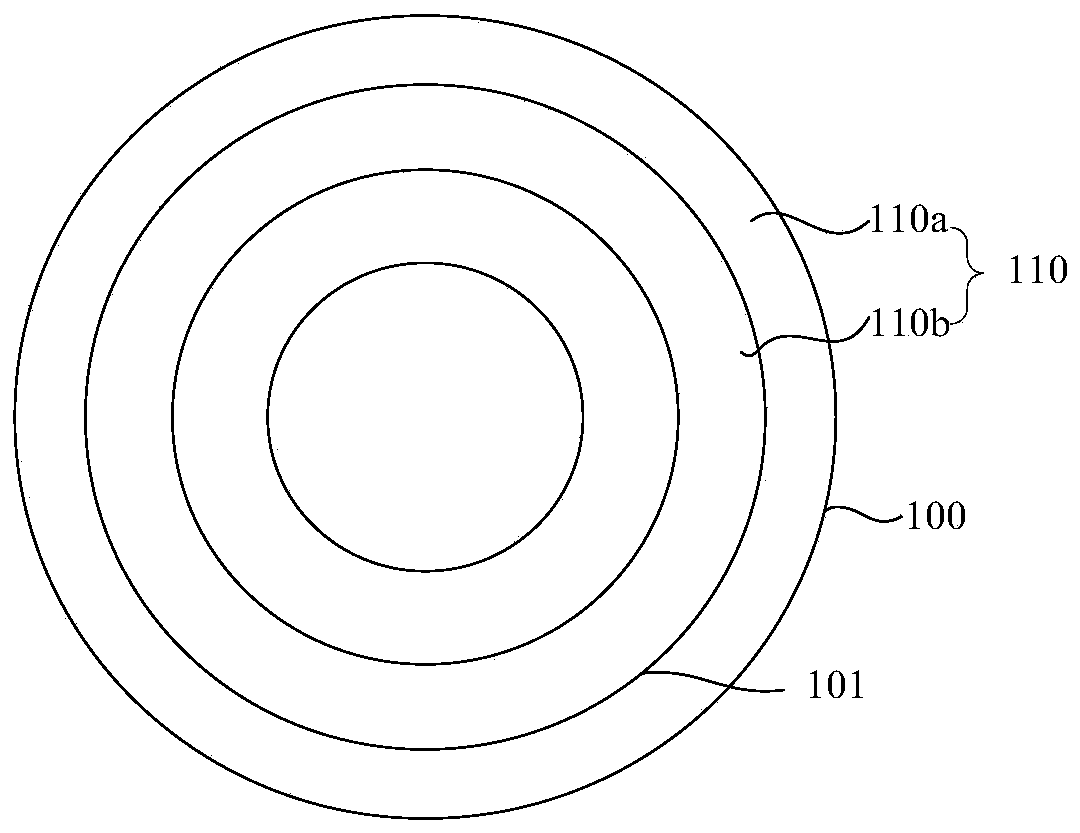

[0032] Please refer to figure 1 , figure 1 It is a schematic flow chart of the wafer film thickness detection method provided by the embodiment of the invention; the embodiment of the present invention provides a wafer film thickness detection method, comprising the following steps:

[0033] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com