A gradient three-dimensional fiber scaffold for integrated regeneration and repair of soft and hard tissues and its preparation method

A fibrous scaffold and hard tissue technology, applied in tissue regeneration, fiber treatment, prosthesis, etc., can solve problems such as difficult to meet the requirements of tissue regeneration and repair, brittleness, poor plasticity, and affect prospects, etc., to achieve fiber shape retention and mechanical strength The effect of performance improvement and mechanical performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Weigh 0.5g of L-polylactic acid and gelatin respectively, add them together to 10ml of trifluoroethanol, stir in a water bath at 37°C for 24h, and rotate at 400rpm to obtain a stable polymer blend solution without obvious phase separation ;

[0039] (2) Spin the blended solution in step (1) by electrospinning process, and receive it on a metal plate to obtain a non-woven fiber membrane. The spinning parameters are: voltage 20kV, receiving distance 15cm, and flow rate 0.8ml / h;

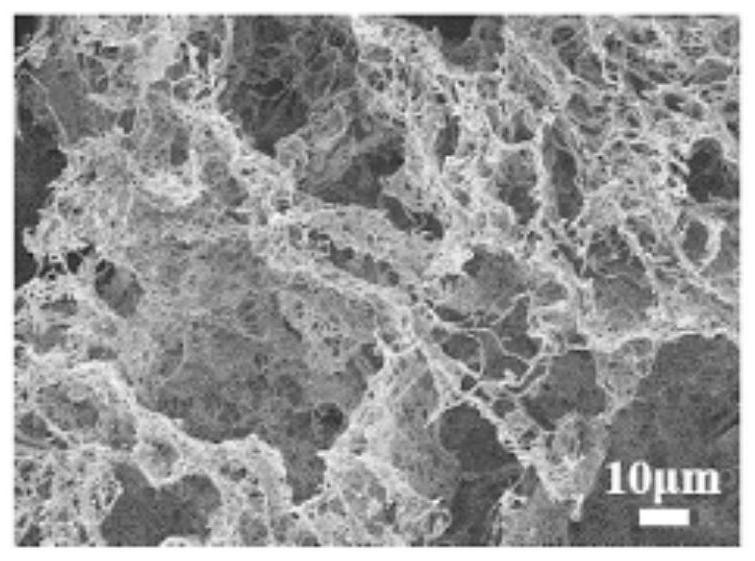

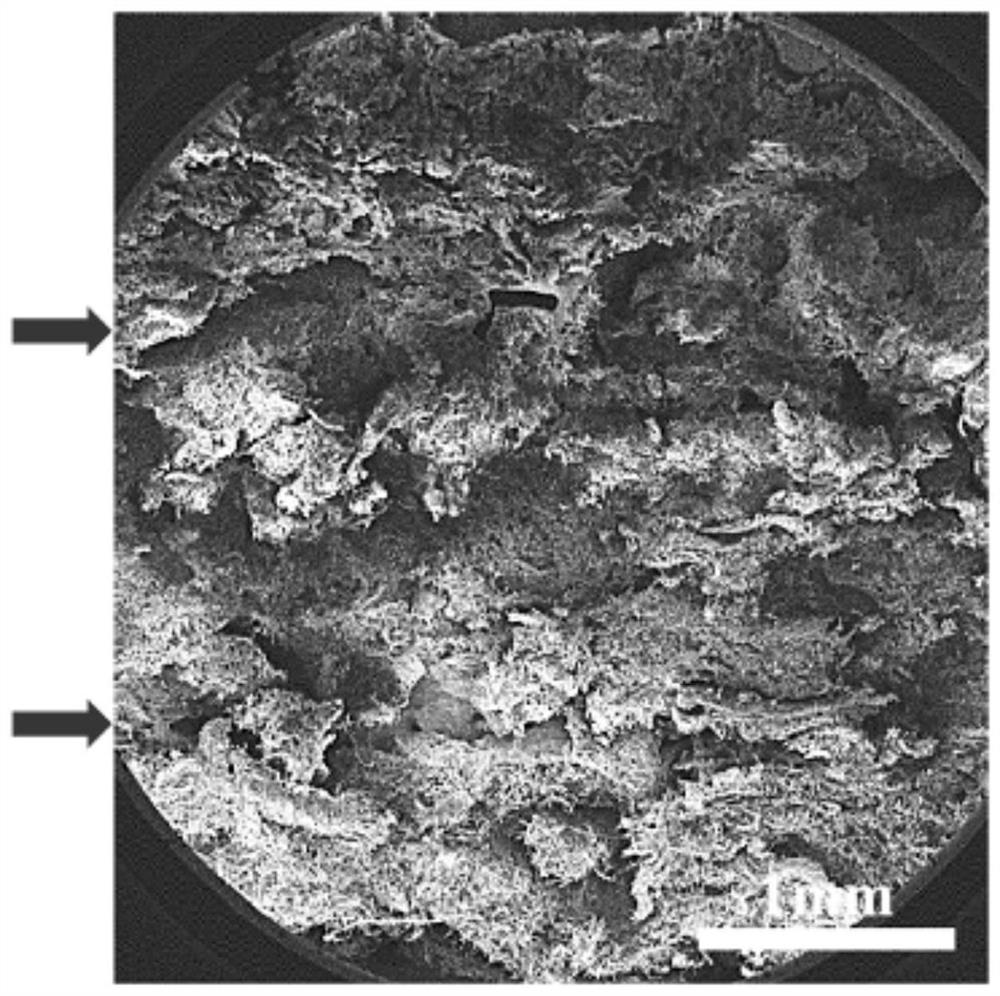

[0040] (3) 0.4g of the fibrous film obtained in step (2) is cut into fragments of 0.5cm×0.5cm, suspended in 20ml of tert-butanol, and sheared at 14000rpm for 20min with a high-speed dispersing homogenizer to obtain uniformly dispersed Fiber suspension, add 8g sodium chloride as porogen and disperse evenly;

[0041] (4) Transfer the suspension obtained in step (3) to a mold (such as a 48-well plate), then freeze at -20°C for 24 hours, and then freeze-dry for 48 hours to obtain a disc-shaped t...

Embodiment 2

[0047] (1) With embodiment 1 step (1)-(5).

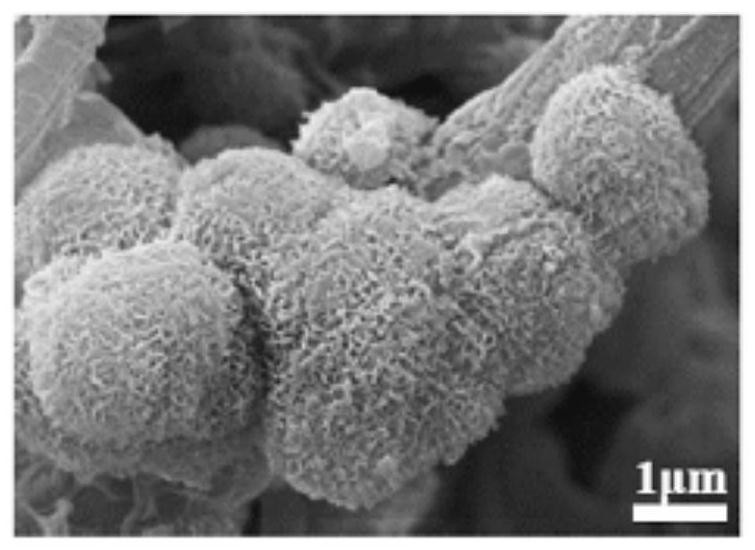

[0048] (2) Soak the obtained polylactic acid / gelatin three-dimensional fiber scaffold in the prepared 5-fold simulated body fluid, soak at 37°C for 24 hours, take out the scaffold and wash it with deionized water, then freeze at -20°C for 24 hours, and then freeze-dry After 48 hours, a three-dimensional fiber scaffold in the middle layer with a mineral deposition amount of 5-20 wt.% was obtained.

Embodiment 3

[0050] (1) With embodiment 1 step (1)-(5).

[0051] (2) Soak the obtained polylactic acid / gelatin three-dimensional fiber scaffold in the prepared 5-fold simulated body fluid, soak at 37°C for 48 hours, take out the scaffold and wash it with deionized water, then freeze at -20°C for 24 hours, and then freeze-dry After 48 hours, a three-dimensional fibrous scaffold with a mineral deposition amount of 20-40wt.% of the hard tissue layer was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com