Continuous preparation method of isomalttol granules

A technology of isomalt and granules, which is applied in the preparation of sugar derivatives, chemical instruments and methods, and granulation in rotating discs/pots, etc., can solve the problems of inability to continuous production, high production energy consumption, high labor intensity, etc. , to achieve the effect of saving capital costs, improving production efficiency, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

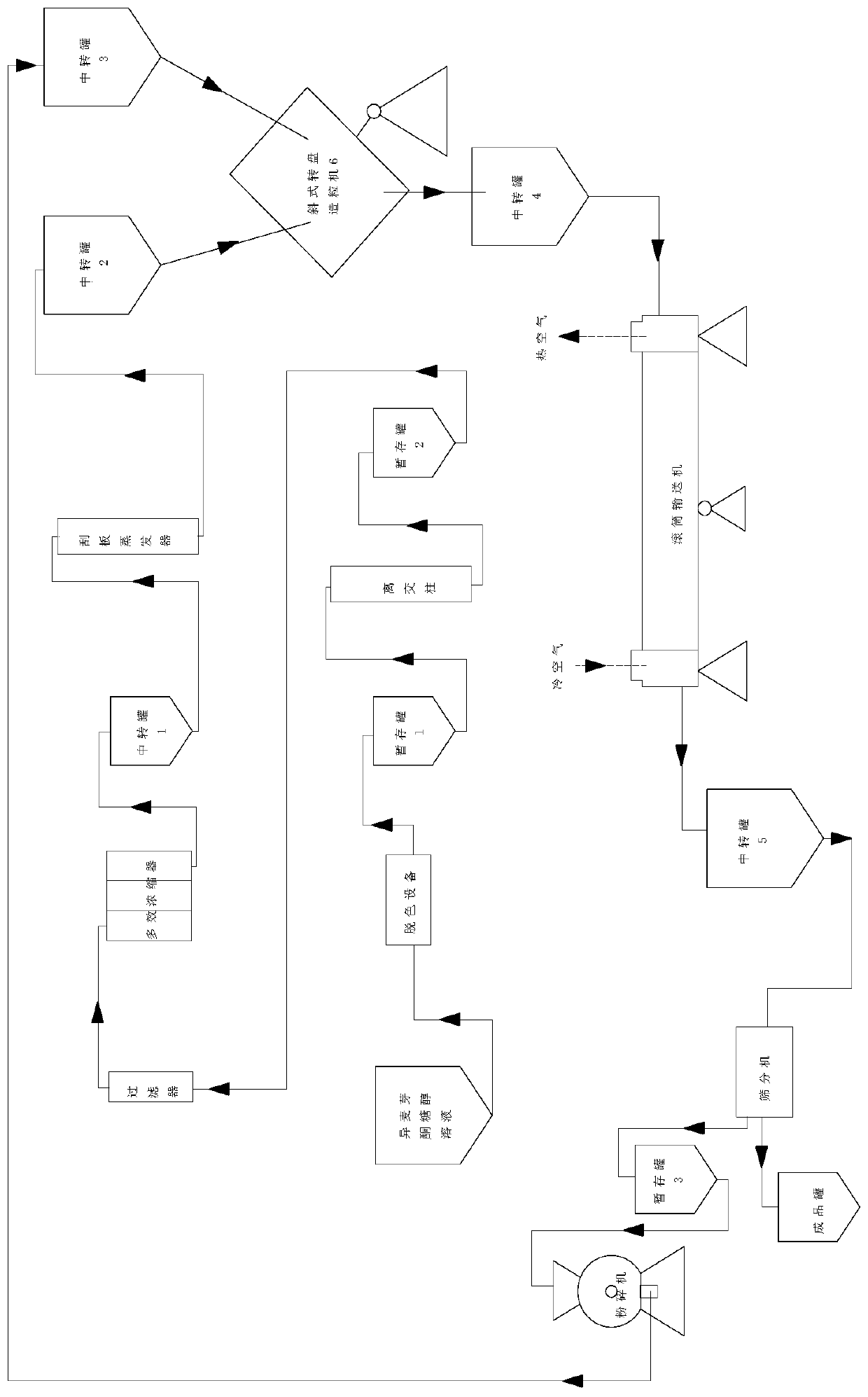

[0027] Such as figure 1 and 2 Shown, a kind of continuous preparation method of isomalt granule, comprises the following steps:

[0028] (1) After decolorization, ion exchange and filtration, the isomalt solution is concentrated by a multi-effect evaporator to a solid content of about 75%, transferred to transfer tank 1 for heat preservation storage, and then transferred to a scraper for evaporation with a pump In the container, it is further concentrated to about 90% of the solid content, and the material is discharged to the transfer tank 2 for insulation;

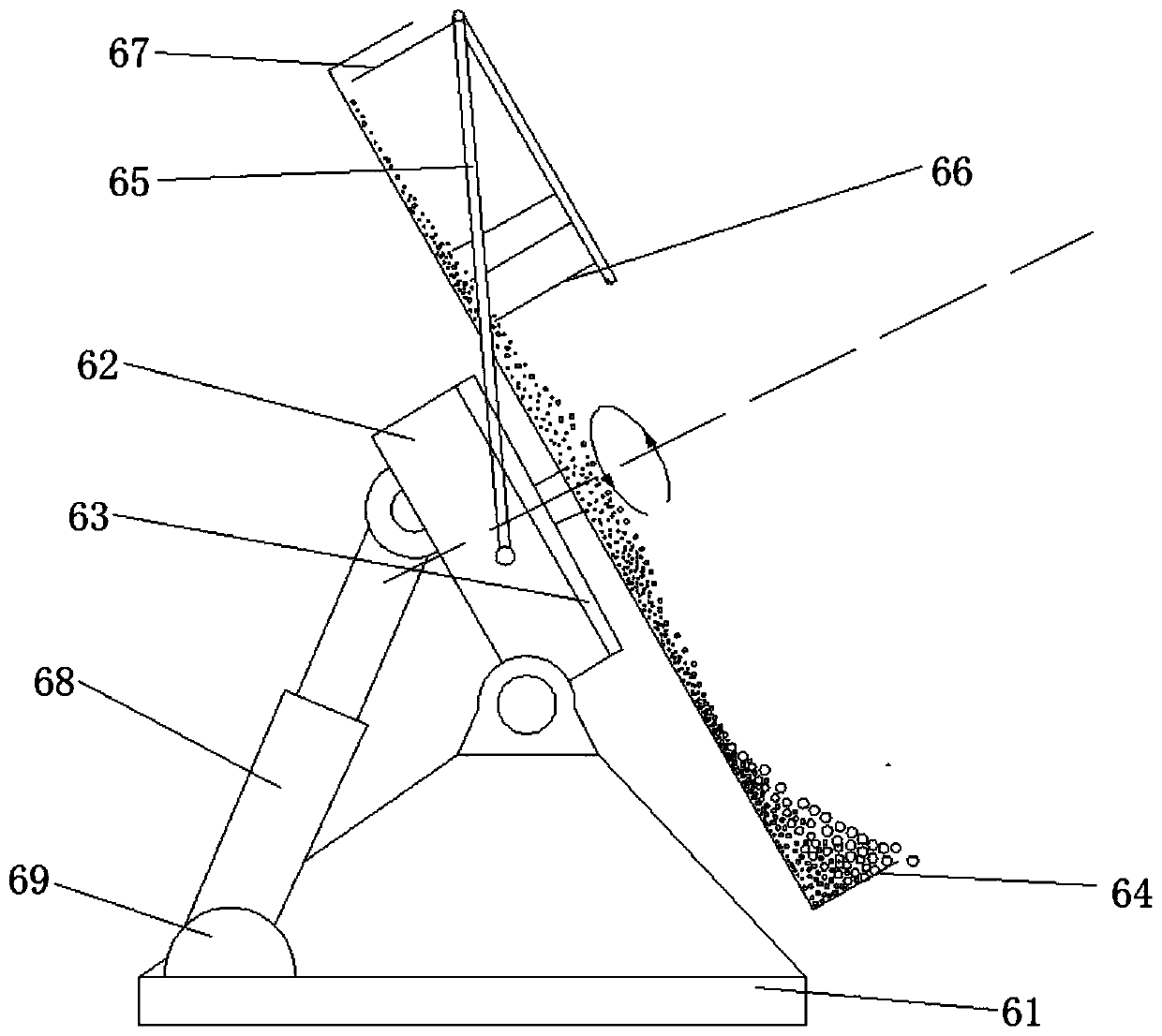

[0029] (2) Use the inclined rotary disc granulator 6 to granulate, first put the isomalt powder into the inclined rotary disc granulator 6 as a seed crystal, and then add the concentrated isomalt liquid to the inclined rotary disc granulator 6. In the rotary disc granulator 6, the isomalt granules are obtained by the inclined rotary disc granulator 6;

[0030] Wherein the inclined rotary disc granulator 6 comprises a ...

Embodiment 2

[0035] A continuous preparation method of isomalt granules, comprising the following steps:

[0036] (1) After decolorization, ion exchange and filtration, the isomalt solution is concentrated by a multi-effect evaporator to a solid content of about 75%, transferred to transfer tank 1 for heat preservation storage, and then transferred to a scraper for evaporation with a pump In the container, it is further concentrated to about 93% of the solid content, and the material is discharged to the transfer tank 2 for insulation;

[0037] (2) Use the inclined rotary disc granulator 6 to granulate, first put the isomalt powder into the inclined rotary disc granulator 6 as a seed crystal, and then add the concentrated isomalt liquid to the inclined rotary disc granulator 6. In the rotary disc granulator 6, the isomalt granules are obtained by the inclined rotary disc granulator 6;

[0038] Wherein the structure of the inclined rotary disc granulator 6 is the same as that in Embodiment...

Embodiment 3

[0042] A continuous preparation method of isomalt granules, comprising the following steps:

[0043] (1) After decolorization, ion exchange and filtration, the isomalt solution is concentrated by a multi-effect evaporator to a solid content of about 75%, transferred to transfer tank 1 for heat preservation storage, and then transferred to a scraper for evaporation with a pump In the container, it is further concentrated to about 90% of the solid content, and the material is discharged to the transfer tank 2 for insulation;

[0044] (2) Use the inclined rotary disc granulator 6 to granulate, first put the isomalt powder into the inclined rotary disc granulator 6 as a seed crystal, and then add the concentrated isomalt liquid to the inclined rotary disc granulator 6. In the rotary disc granulator 6, the isomalt granules are obtained by the inclined rotary disc granulator 6;

[0045] Wherein the structure of the inclined rotary disc granulator 6 is the same as that in Embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap