A machining device for box-shaped electronic components

An electronic component and mechanical processing technology, which is applied in the field of mechanical processing devices for box-shaped electronic components, can solve the problems of increased difficulty, small size, and difficulty in taking out electronic components, so as to improve stability, improve buffering effect, and improve stamping. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

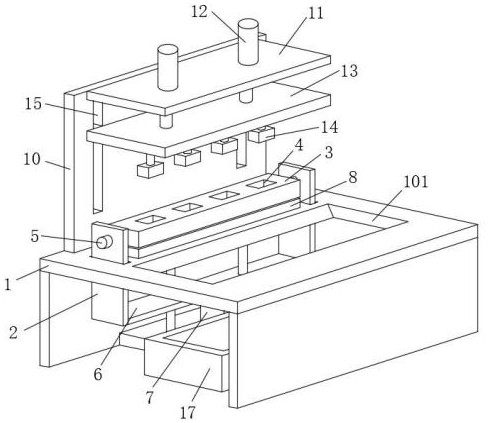

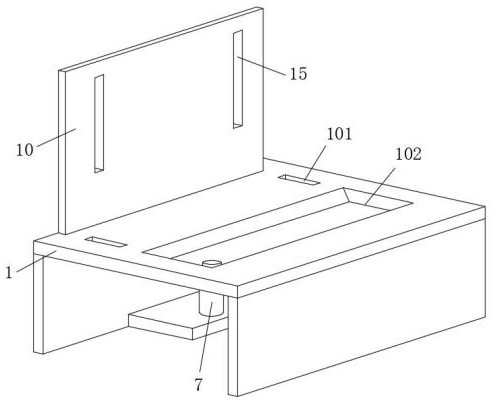

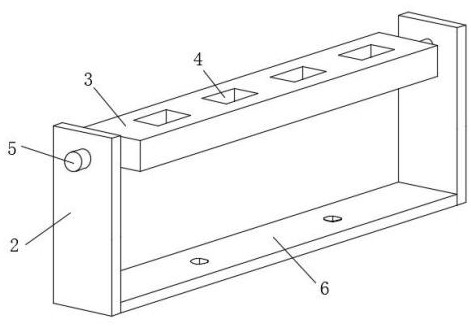

[0040] see Figure 1-3 , a machining device for box-shaped electronic components, comprising an operating table 1, lifting plates 2 slidably connected to both sides of the upper end of the operating table 1, and a workpiece placement plate rotatably installed between the two lifting plates 2 near the upper ends of the opposite side walls 3. Both sides of the upper end of the console 1 are provided with hollow cavities 101 for the elevating plate 2 to penetrate through. The first electric telescopic cylinder 7 that drives the bottom plate 6 is fixedly installed, and the outer wall of the upper end of one of the lifting plates 2 is fixedly installed with a rotating motor 5 that drives the workpiece placing plate 3, and the upper ends of the workpiece placing plate 3 are equally spaced along the horizontal direction A plurality of workpiece stamping grooves 4 are provided, and the inner walls of the plurality of workpiece stamping grooves 4 are coated with nano-wear-resistant coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com