Sliding type building plastic template punching machine

A plastic formwork and sliding technology, which is applied in the field of punching machines, can solve the problems of damage to plastic building formwork and the bottom of the hole is large, etc., and achieve the effect of precise punching position and prevention of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

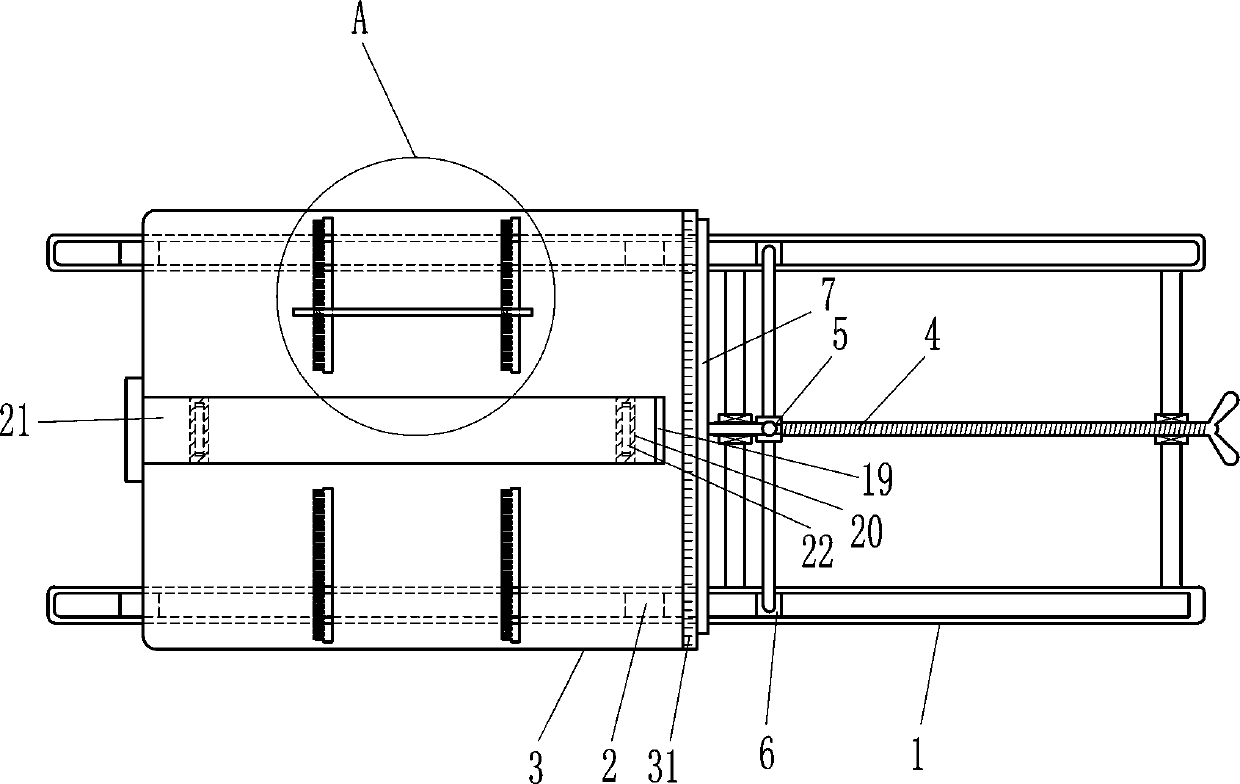

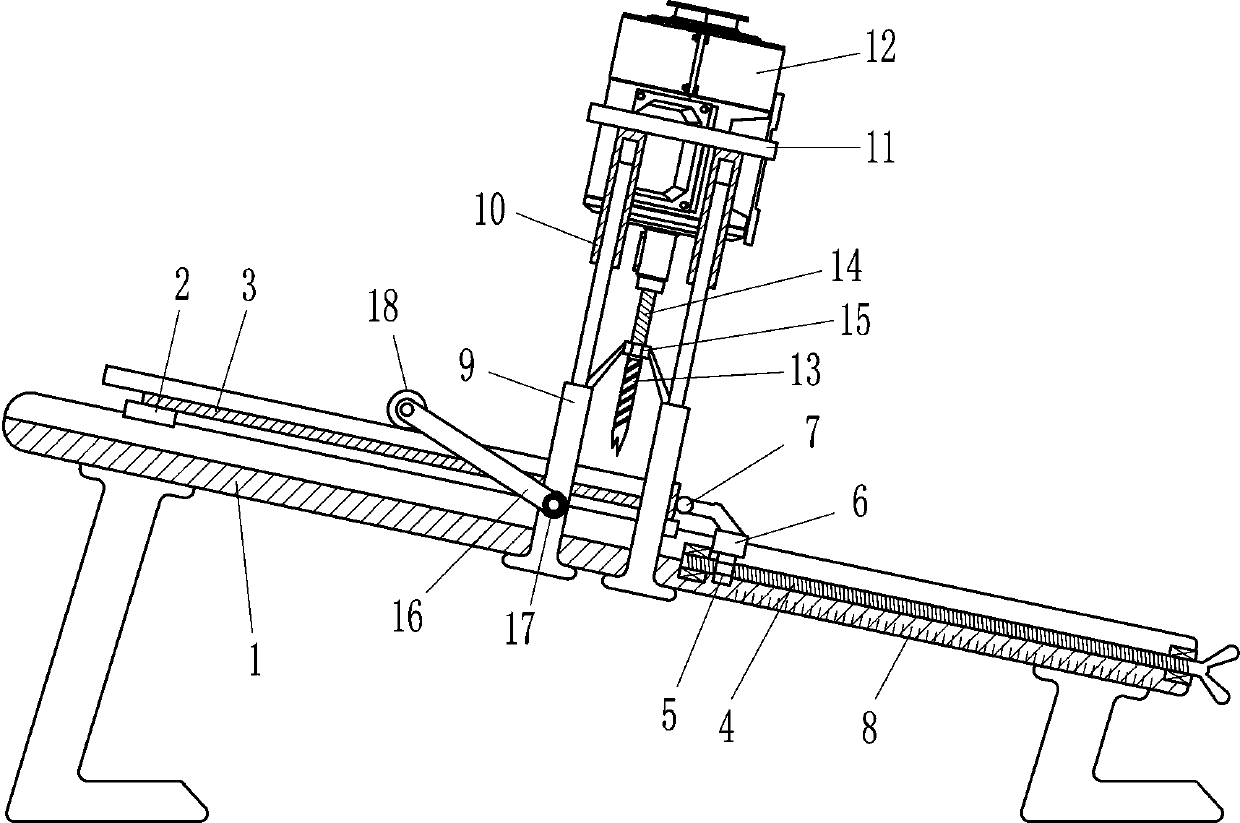

[0020] A sliding type construction plastic formwork puncher, such as figure 1 and 2 As shown, it includes a track 1, a sliding placement part, a limiting part and a punching part. There are two track 1s. There is a position-limiting component that is limited by rotation, and the middle part of the track 1 is provided with a punching component that is drilled by rotation.

[0021] like figure 1 and 2 As shown, the sliding part includes a first slider 2 and an L-shaped plate 3, and two first sliders 2 are slidably connected to the left and right parts of the track 1, and the tops of the first sliders 2 are fixed with L Shaped plate 3, the right side of the top of the L-shaped plate 3 is engraved with a first scale 31.

[0022] like figure 1 and 2 As shown, the limiting component includes a screw mandrel 4, a first nut 5, a second slider 6 and a limit rod 7, and a screw mandrel 4 is rotatably connected between the right part of the track 1, and a first screw mandrel 4 is sc...

Embodiment 2

[0029] like figure 1 As shown, on the basis of Embodiment 1, in order to punch holes more stably, it also includes a swing lever 16, a torsion spring 17 and a pressure roller 18, and the lower parts of the brackets 9 on the front and rear sides are connected to the swing lever 16 in a rotational manner. A torsion spring 17 is provided at the rotational connection of the swing rod 16 , and a pressure roller 18 is rotationally connected between the outer ends of the swing rod 16 .

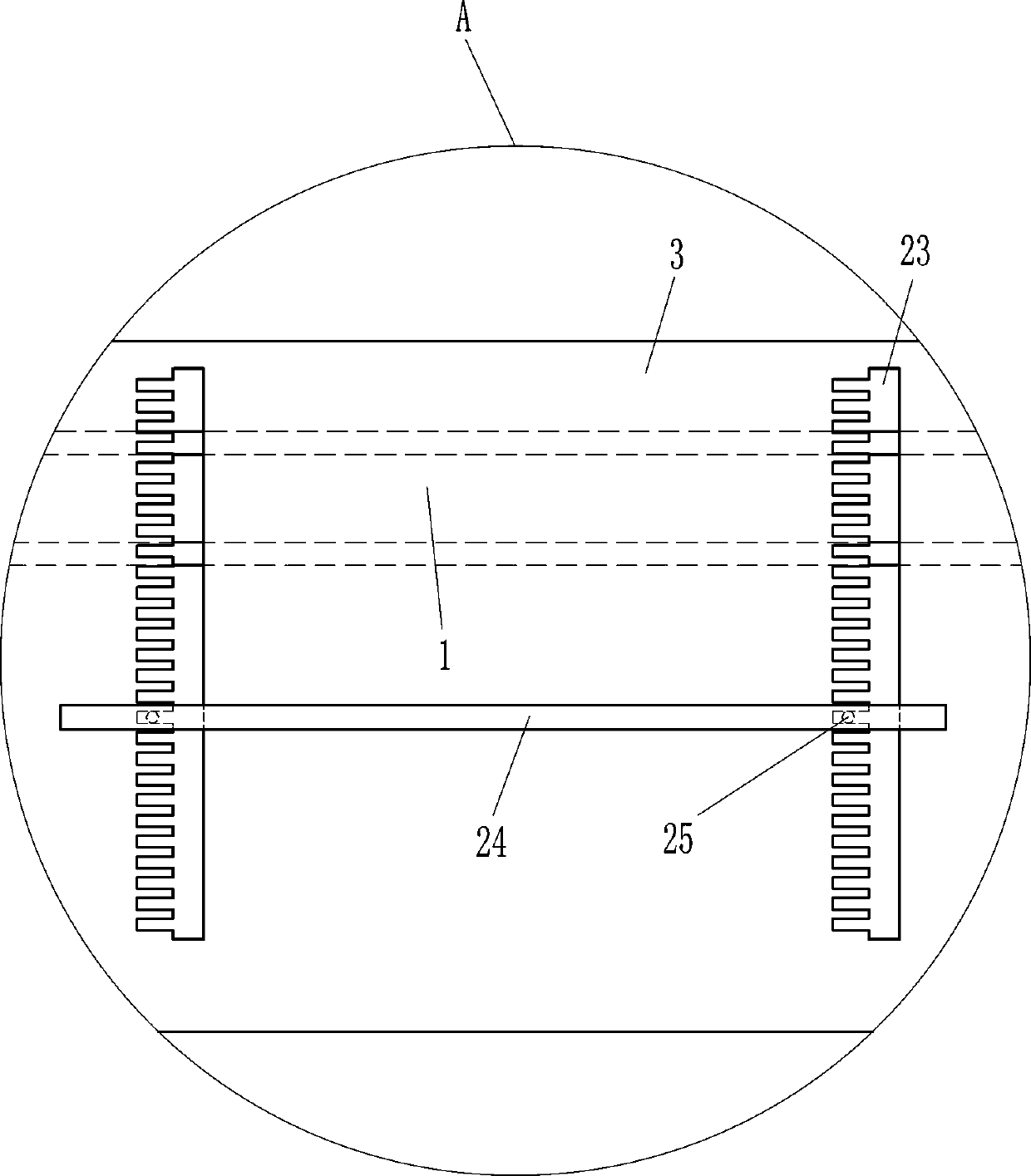

[0030] like figure 2 As shown, in order to prevent the building plastic formwork from being damaged, it also includes a concave backing plate 20, an inserting plate 21 and a block 22, and the left middle part of the L-shaped plate 3 has a groove 19, and the left and right parts in the groove 19 are all provided with There is a concave backing plate 20 on which a flashboard 21 is placed, and the left and right sides of the bottom of the flashboard 21 are provided with blocks 22 , and the snap blocks...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap