Jaw loading and unloading mechanism of novel injection molding six-axle manipulator loading machine

A six-axis manipulator and gripper technology, applied in coating and other directions, can solve the problems of difficulty in ensuring the safety of operators and working environment, multi-manpower, material resources and time, reducing production and processing efficiency, etc., to facilitate production control and guarantee. The effect of personal safety and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

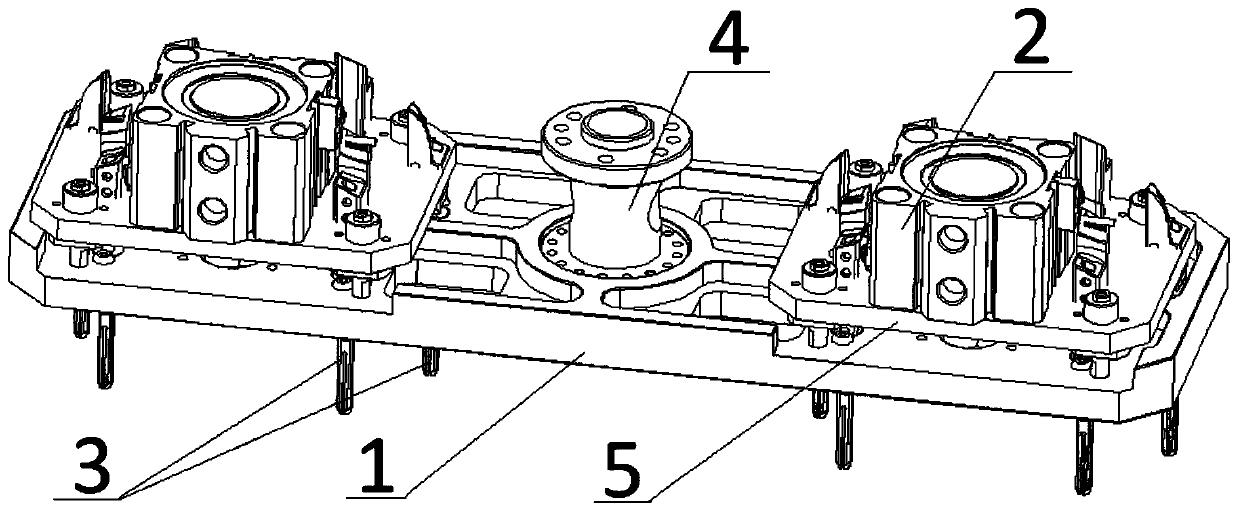

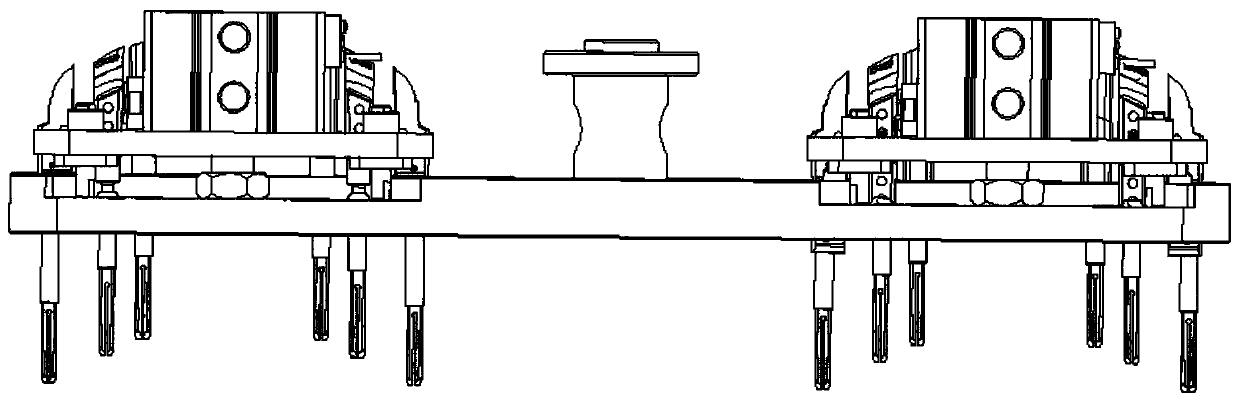

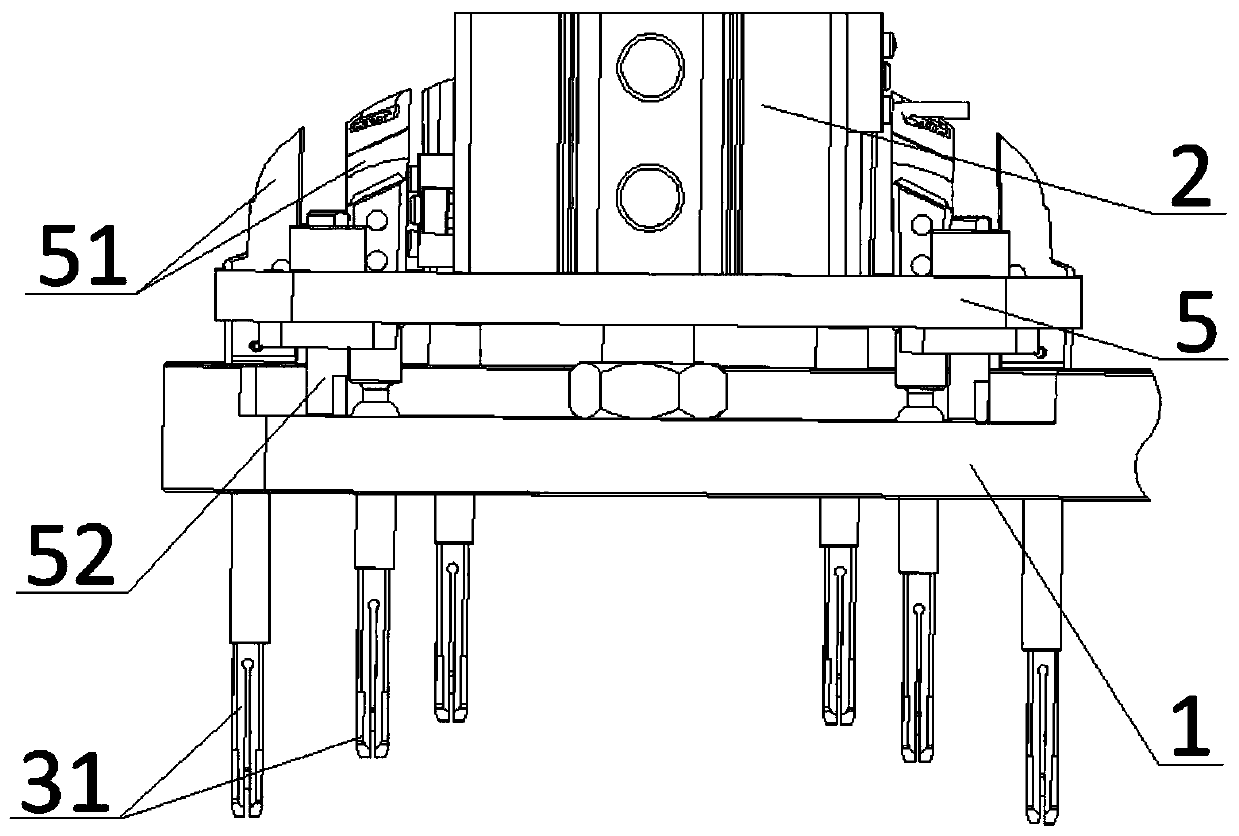

[0018] figure 1 It schematically shows the structure of a new type of injection molding six-axis manipulator loading machine jaw loading and unloading mechanism according to an embodiment of the present invention, figure 2 shown figure 1 The front structure of the jaw loading and unloading mechanism of the new injection molding six-axis manipulator loading machine, image 3 shown figure 2 part of the structure. Such as Figure 1-3 As shown, the mechanism includes a frame plate 1, which is roughly rectangular, and the middle parts of which can be set as solid or hollowed out as required. Both ends of one side of the shelf 1 are provided with a cylinder 2, the cylinder 2 is movably installed on the shelf 1, and its push rod extends toward the shelf 1 and is connected to the shelf 1, which can push the shelf 1 to make the two move relative to each other....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com