Molecular sieve pneumatic quantitative filling device and method

A technology of molecular sieve and pneumatic switch, which is applied in the direction of transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problem of molecular sieve balls easily blocking the filling hole entrance of cryogenic gas cylinders, molecular sieve adsorption capacity and activity reduction, and molecular sieve manual filling time Long and other problems, to achieve the effect of improving processing efficiency and product quality, reducing filling time and reducing production operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

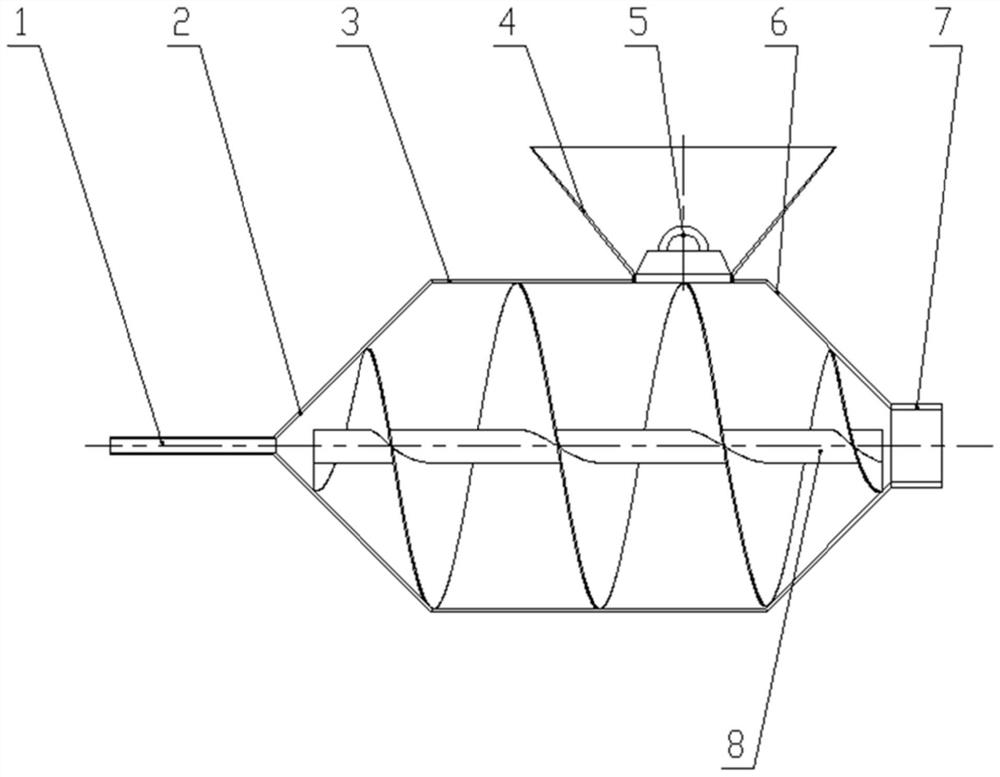

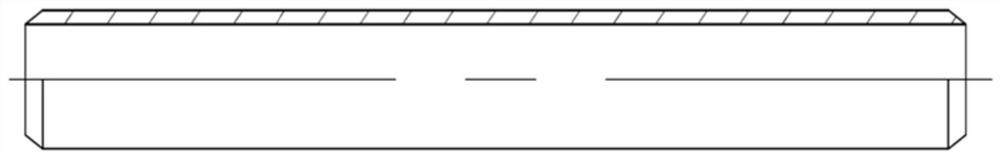

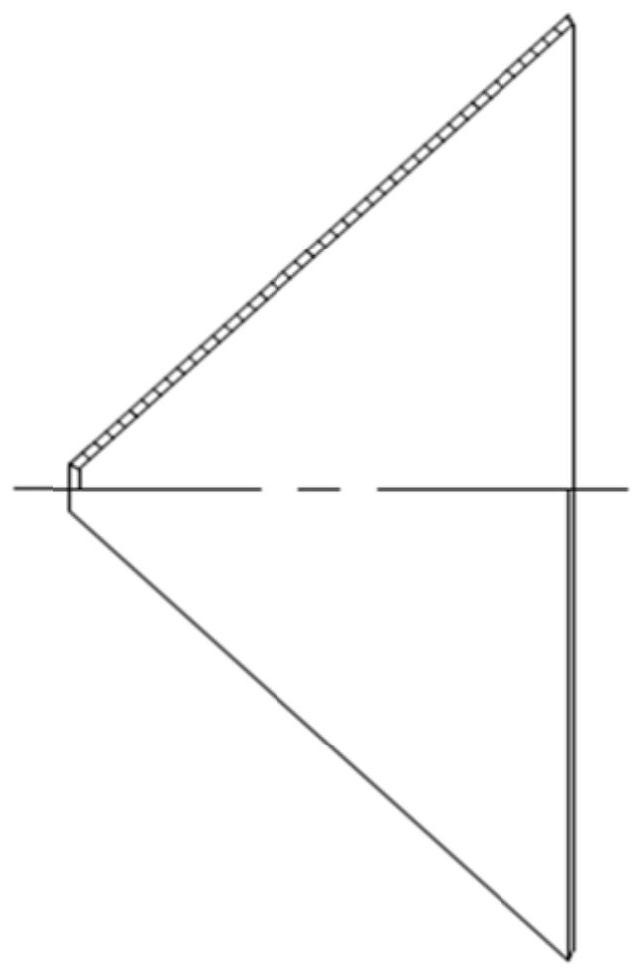

[0019] The present invention is a molecular sieve pneumatic quantitative filling device, which includes a discharge pipe 1, a front cone 2, a silo section 3, a hopper 4, a hopper cover 5, a rear cone 6, a pneumatic joint 7 and a spiral plate 8.

[0020] The front vertebral body 2, the silo section 3, and the rear vertebral body 5 are fixed and sealed to form a silo;

[0021] The spiral plate 8 is fixed on the inside of the silo, which can prevent the molecular sieve from colliding and flying randomly in the pneumatic device. Preferably, the spiral plate 8 and the silo cannot rotate with each other;

[0022] The silo section 3 is provided with a feed port for filling the molecular sieve in the feed bin, and a hopper 4 is arranged around the feed port to facilitate molecular sieve filling;

[0023] The feed inlet is provided with a hopper cover 5 corresponding to the feed inlet, and the hopper cover 5 and the feed inlet are preferably threaded or connected with a vacuum plug;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com