Construction method of inverted-splayed cast-in-place arc-shaped wing web formwork system

A construction method, the inverted horoscope technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems that steel molds are easily affected by weather and humidity, increase the difficulty of formwork assembly, increase construction labor costs, etc., and achieve the setting of the wing plate Convenient support, reduce mechanical noise pollution, and reduce the effect of customization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

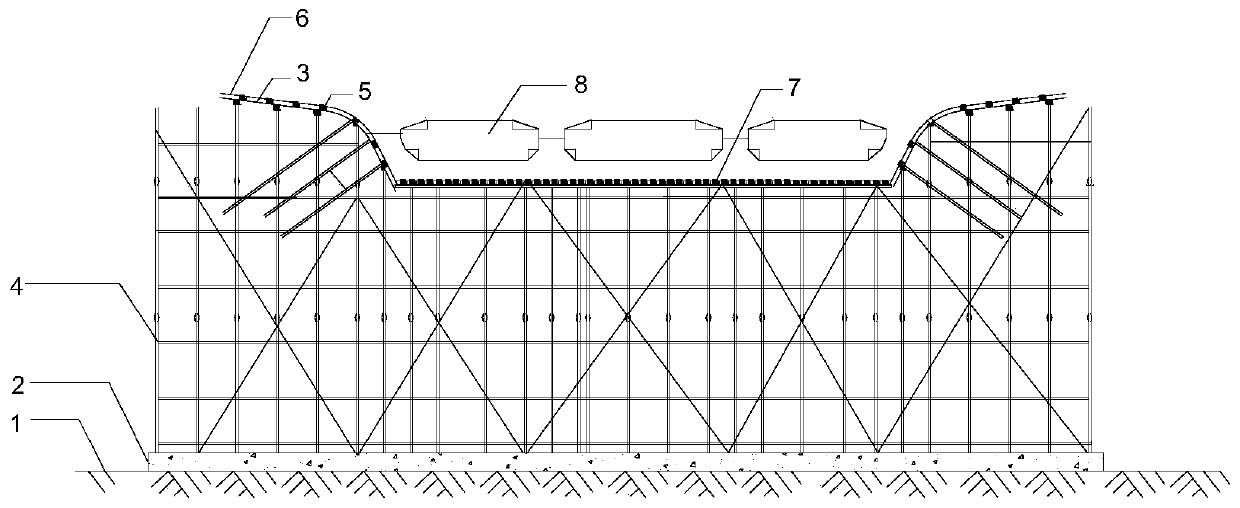

[0026] For the construction method of the inverted splayed cast-in-place curved wing web formwork system, please refer to figure 1 , figure 2 , image 3 , Figure 4 , including the following steps:

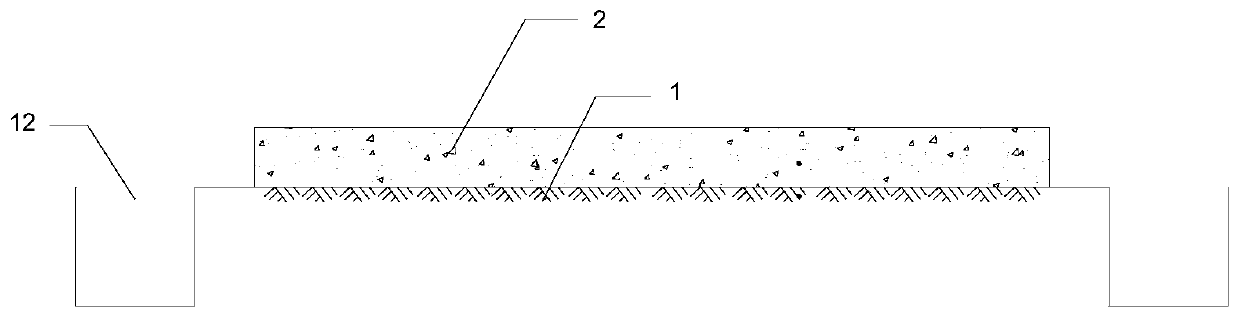

[0027] (1) Site leveling and foundation treatment

[0028] Lay a 10-15m thick C20 concrete cushion on the foundation and build drainage ditches on both sides of the foundation, and control the degree of compaction of the foundation to ≥93%;

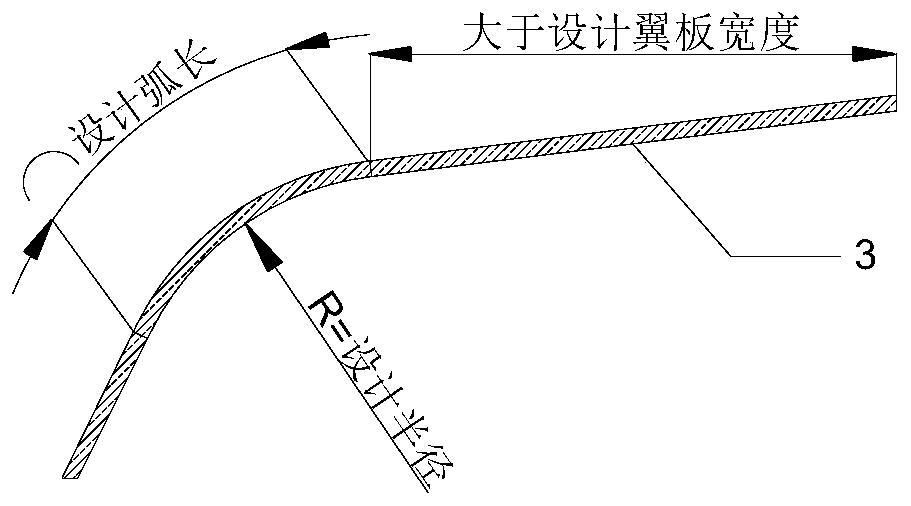

[0029] (2) Bending curved steel pipe

[0030] see image 3 , the curved steel pipe is made of Φ48*3.5mm steel pipe. Specifically, according to the size of the box girder and the reserved length, calculate and determine the arc length, radius, arc starting point and arc end point of the curved steel pipe, and the arc end point and the end of the curved steel pipe The distance should be greater than the design width of the wing plate; use the steel bar bending machine on the market, set the axis of the bending machine as the center, put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com