Device and method for detecting scattered light based on cooperation of ultrasonic modulation

A sub-surface defect and detection device technology, which is applied in the direction of measuring device, optical testing of flaws/defects, and material analysis using sound waves/ultrasonic waves/infrasonic waves, etc., can solve the problem of ignoring damage dynamic changes and being unable to respond to sub-surface non-visual defects, etc. problem, to achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

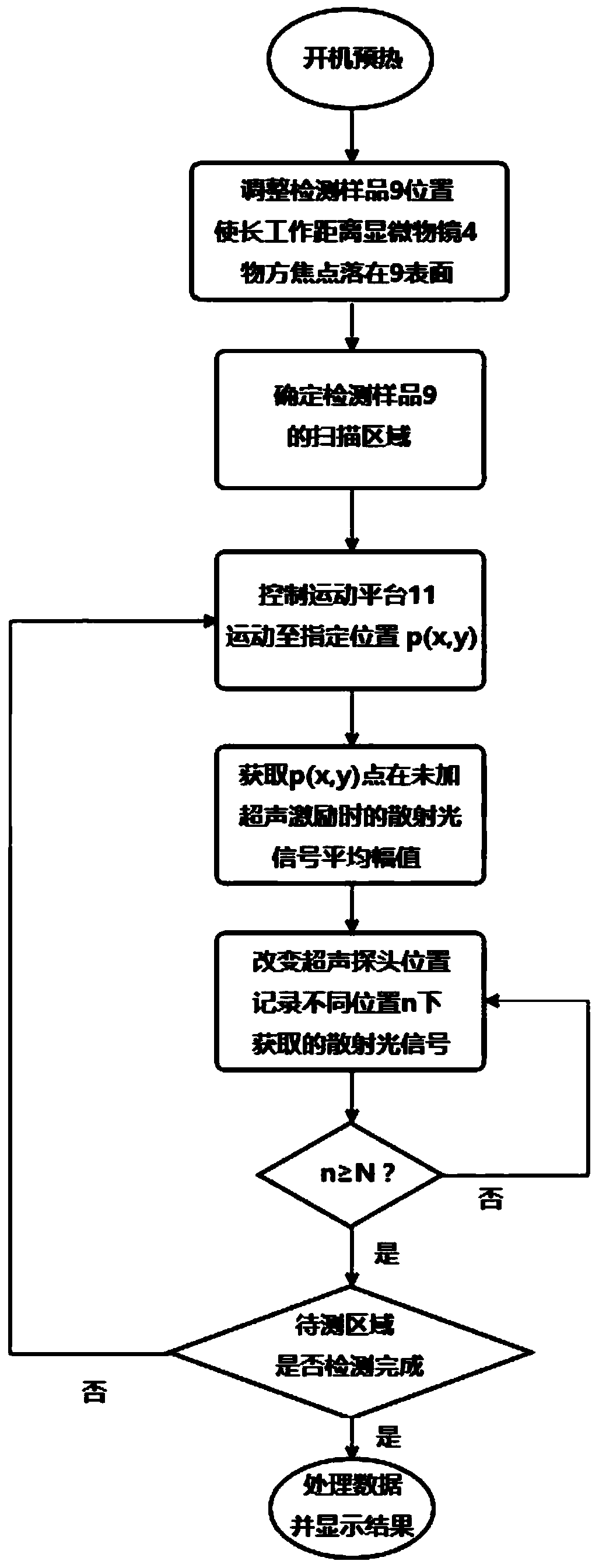

[0033] The present invention will be specifically described below in conjunction with the accompanying drawings and this embodiment.

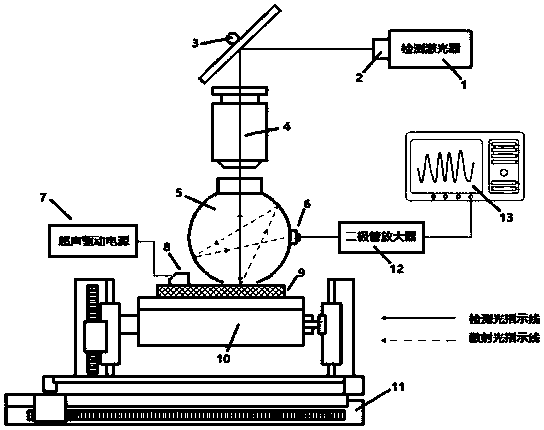

[0034] like figure 1 As shown, the subsurface defect detection device of the present invention includes an ultrasonic excitation device, a laser scattering detection device, a motion platform 11 and a sample stage 10;

[0035] The sample stage 10 is fixed on the motion platform 11, and the detection sample 9 is placed on the sample stage 10; the motion platform 11 drives the detection sample 9 to move in the X, Y, Z three-dimensional space, and scans and detects the surface and sub-surface of the detection sample 9;

[0036] The ultrasonic excitation device comprises an ultrasonic drive power supply 7 and an ultrasonic probe 8; the type of acoustic waves excited by the ultrasonic probe 8 on the test sample 9 is a surface wave; the ultrasonic probe 8 is fixed on the test sample 9 surface and is in close contact with the test sample 9 surface , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com