Portable concrete slump test device for municipal road engineering

A test device and portable technology, which is applied in the field of portable concrete slump test devices for municipal highway engineering, can solve the problems of inaccurate measurement, slump cylinder tilting, affecting the shape of concrete, etc. Flexible, effect-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

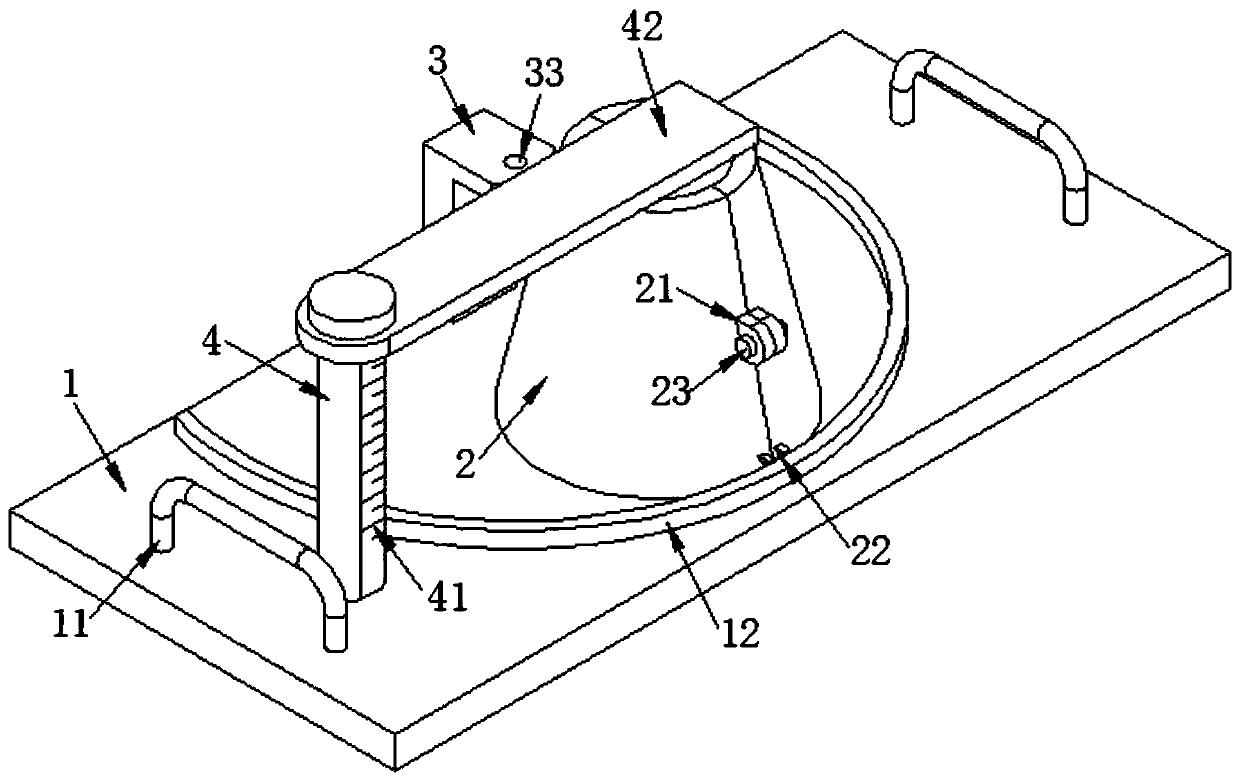

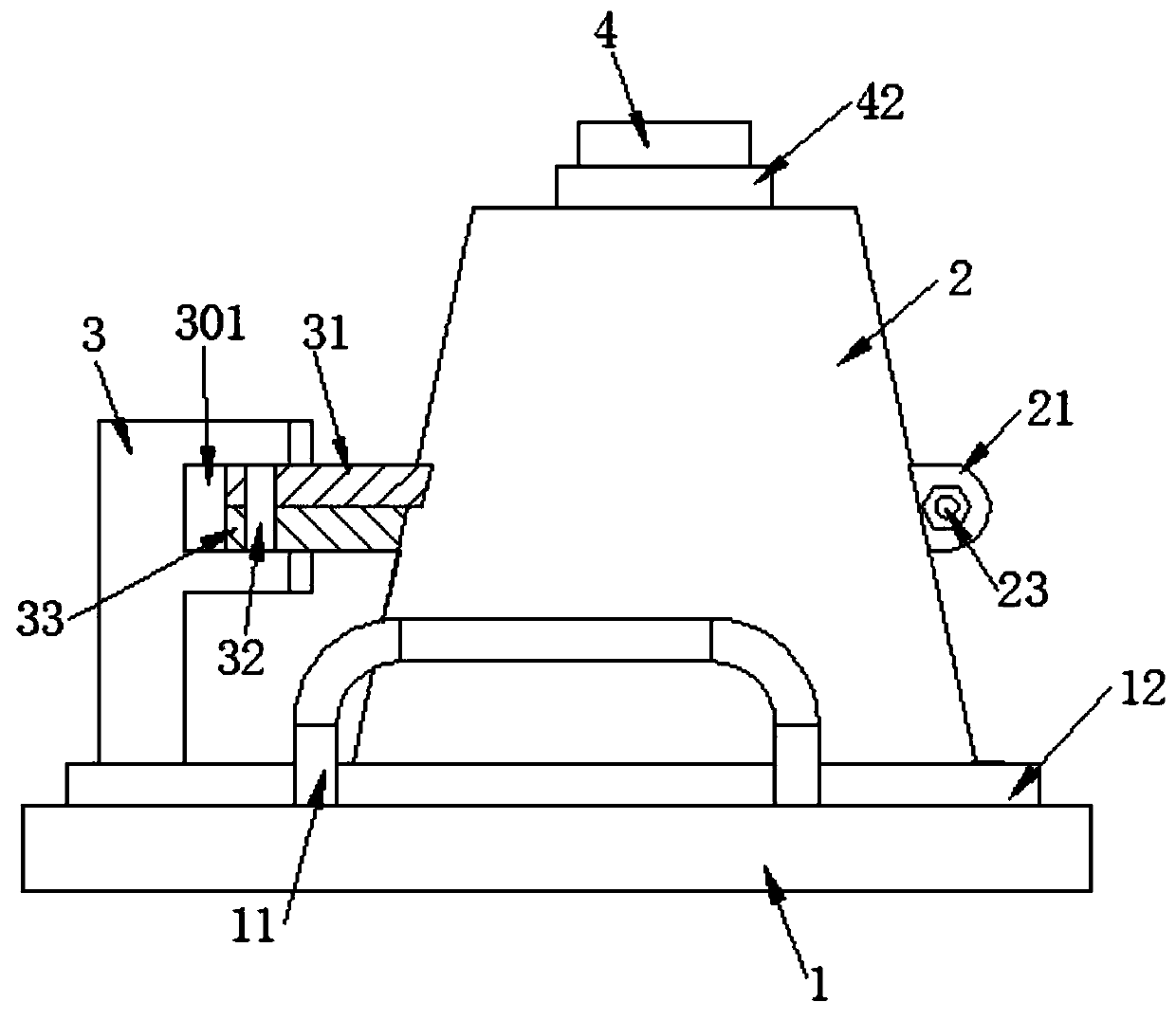

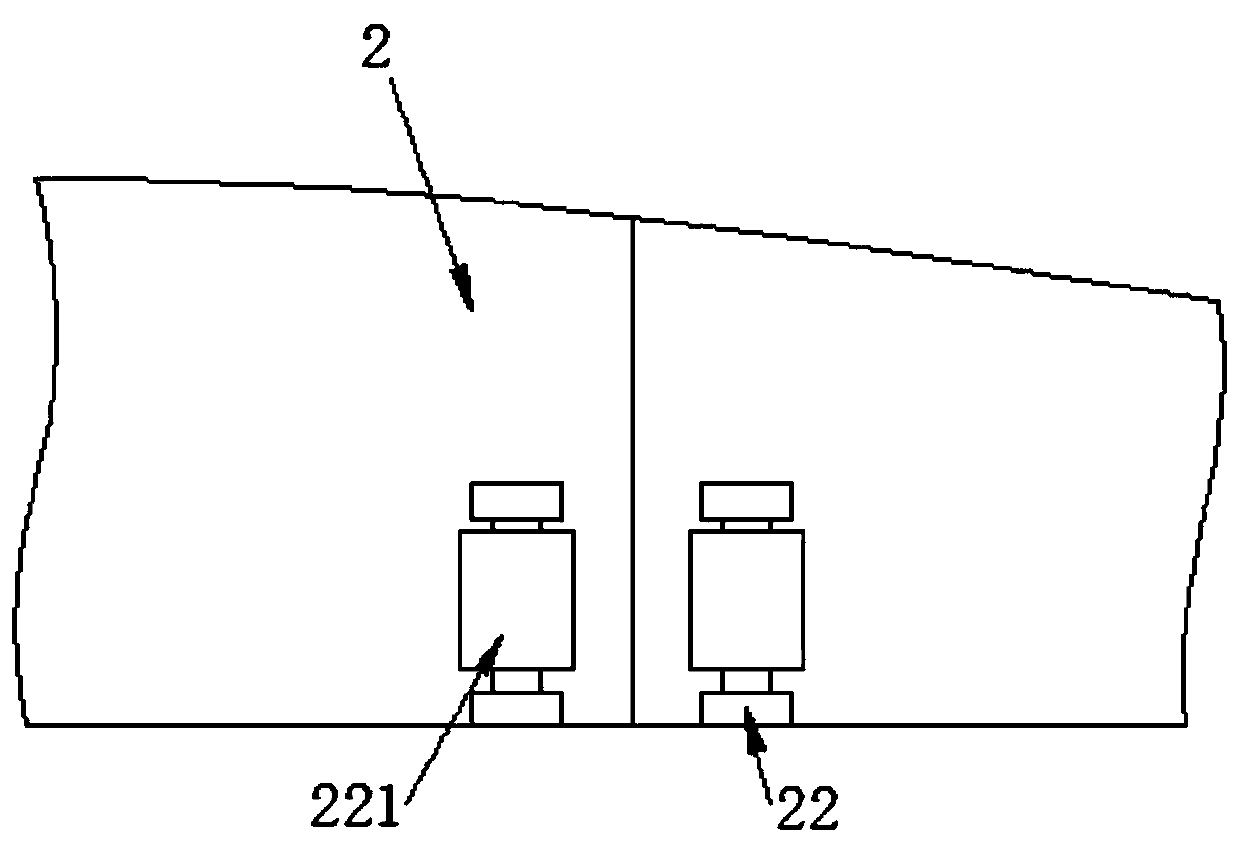

[0020] see Figure 1~4 , in an embodiment of the present invention, a portable concrete slump test device for municipal highway engineering, comprising a bottom plate 1, two semi-cone cylinders 2 are arranged on the top of the bottom plate 1, and a mounting seat 3 is fixedly connected to the top of the bottom plate 1, and the mounting seat 3 There is an avoidance groove 301, and the inner side of the avoidance groove 301 is connected with the first fixed plate 31 and the second fixed plate 32 through the rotation shaft 33, the first fixed plate 31 is located on the top of the second fixed plate 32, and the first fixed plate 31, the second fixed plate The two fixing plates 32 are respectively fixed with the two half-type cones 2, the top of the bottom plate 1 is fixedly connected with a positioning ring 12, and the bottoms of the outer walls of the two half-type cones 2 are fixedly connected with two connecting plates 22, and the two connecting plates 22 There is a roller 221 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com