Waveform recognition method and device for movement of servo welding system

A welding system and waveform recognition technology, applied in character and pattern recognition, motor generator testing, measuring devices, etc., can solve the problems of high cost of sensor deployment and transformation, occupation of communication resources, etc., to achieve consistency and save communication resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

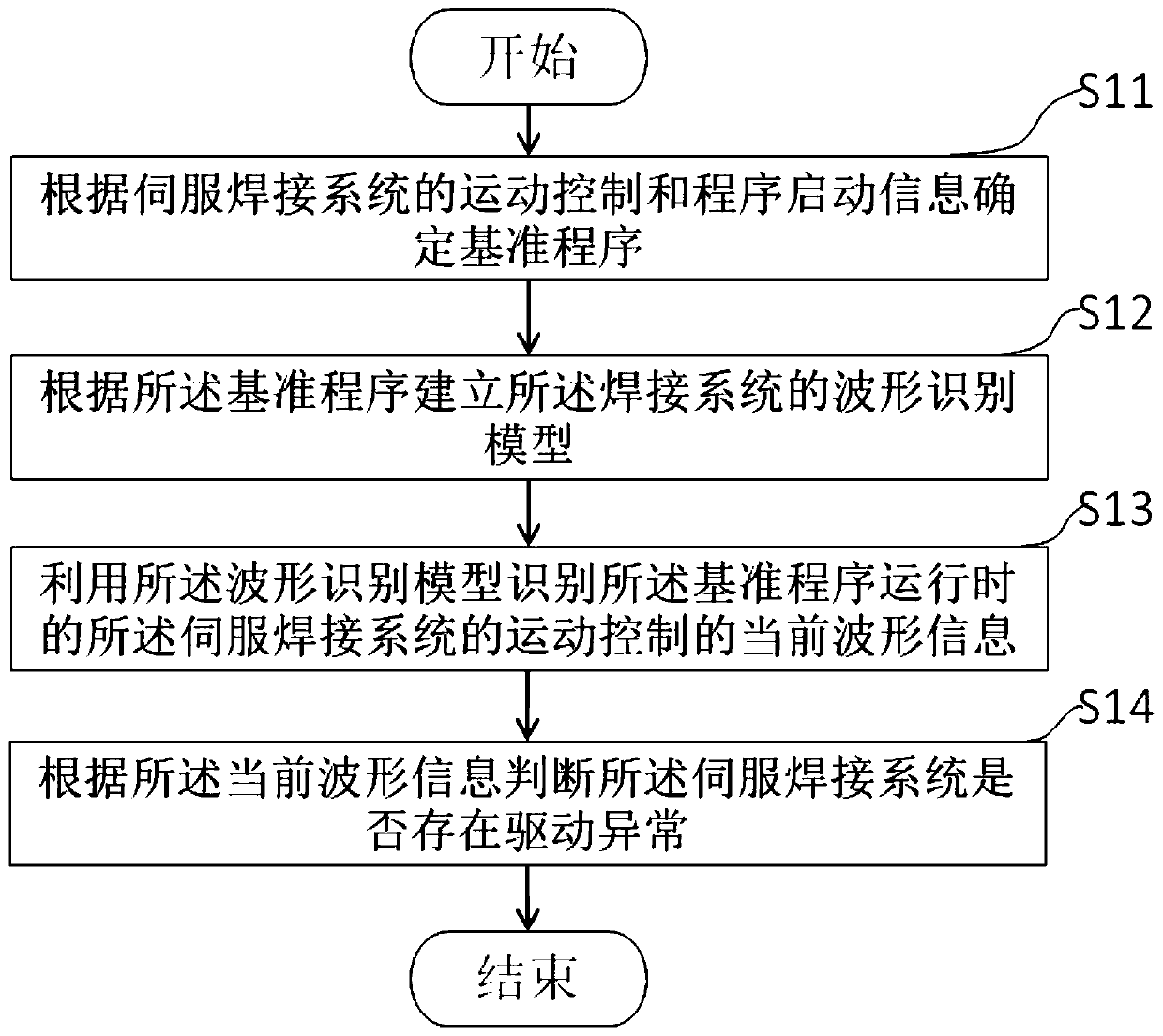

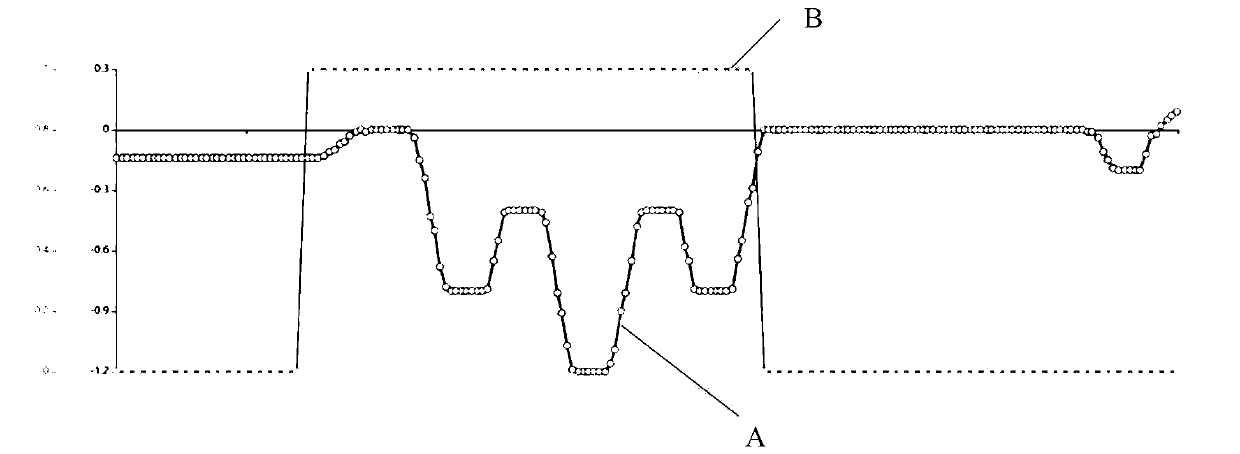

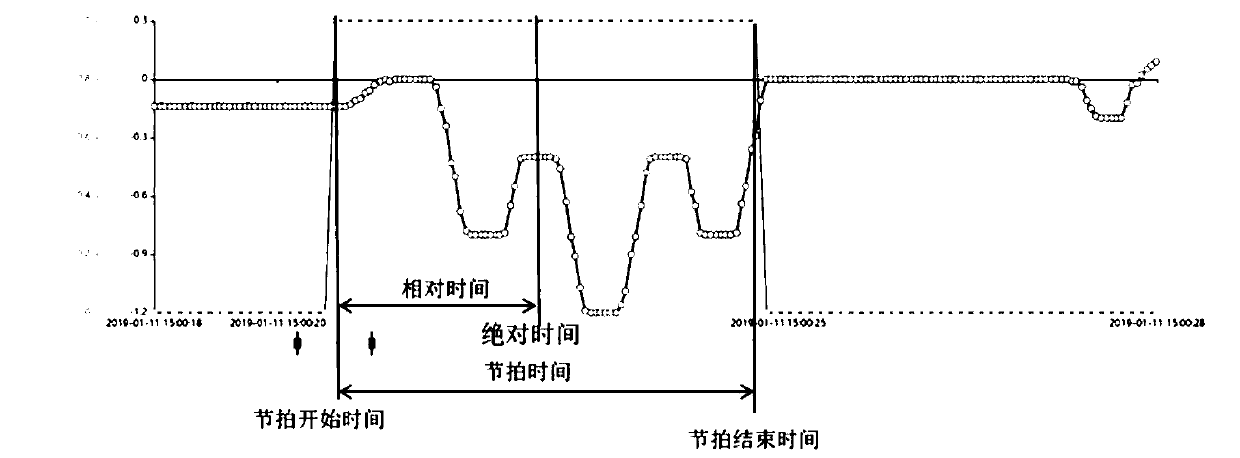

[0046] The application will be described in further detail below in conjunction with the accompanying drawings.

[0047] In a typical configuration of this application, the terminal, the device serving the network, and the trusted party all include one or more processors (such as a central processing unit (Central Processing Unit, CPU)), an input / output interface, a network interface, and a memory .

[0048] Memory may include non-permanent memory in computer-readable media, random access memory (Random Access Memory, RAM) and / or non-volatile memory, such as read-only memory (Read Only Memory, ROM) or flash memory (flash RAM). Memory is an example of computer readable media.

[0049] Computer-readable media, including both permanent and non-permanent, removable and non-removable media, can be implemented by any method or technology for storage of information. Information may be computer readable instructions, data structures, modules of a program, or other data. Examples o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com