Railway track defect detection method and system

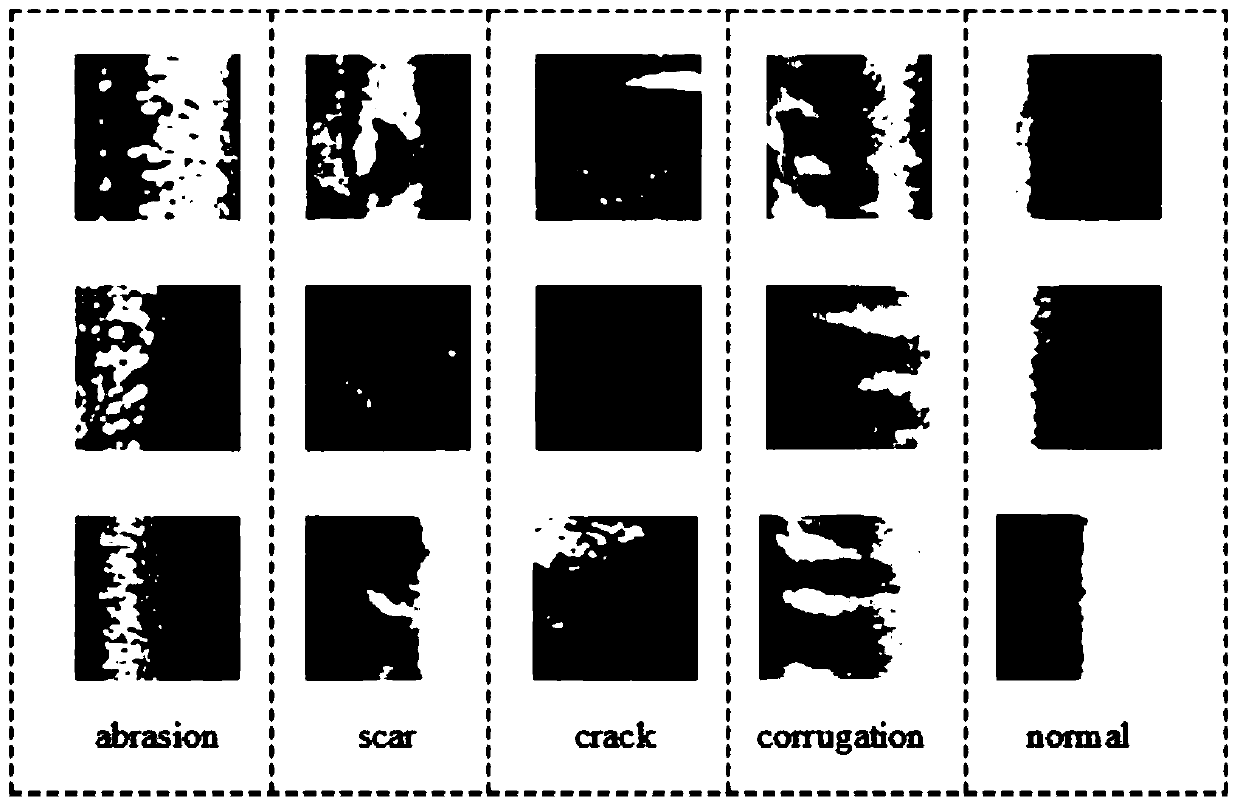

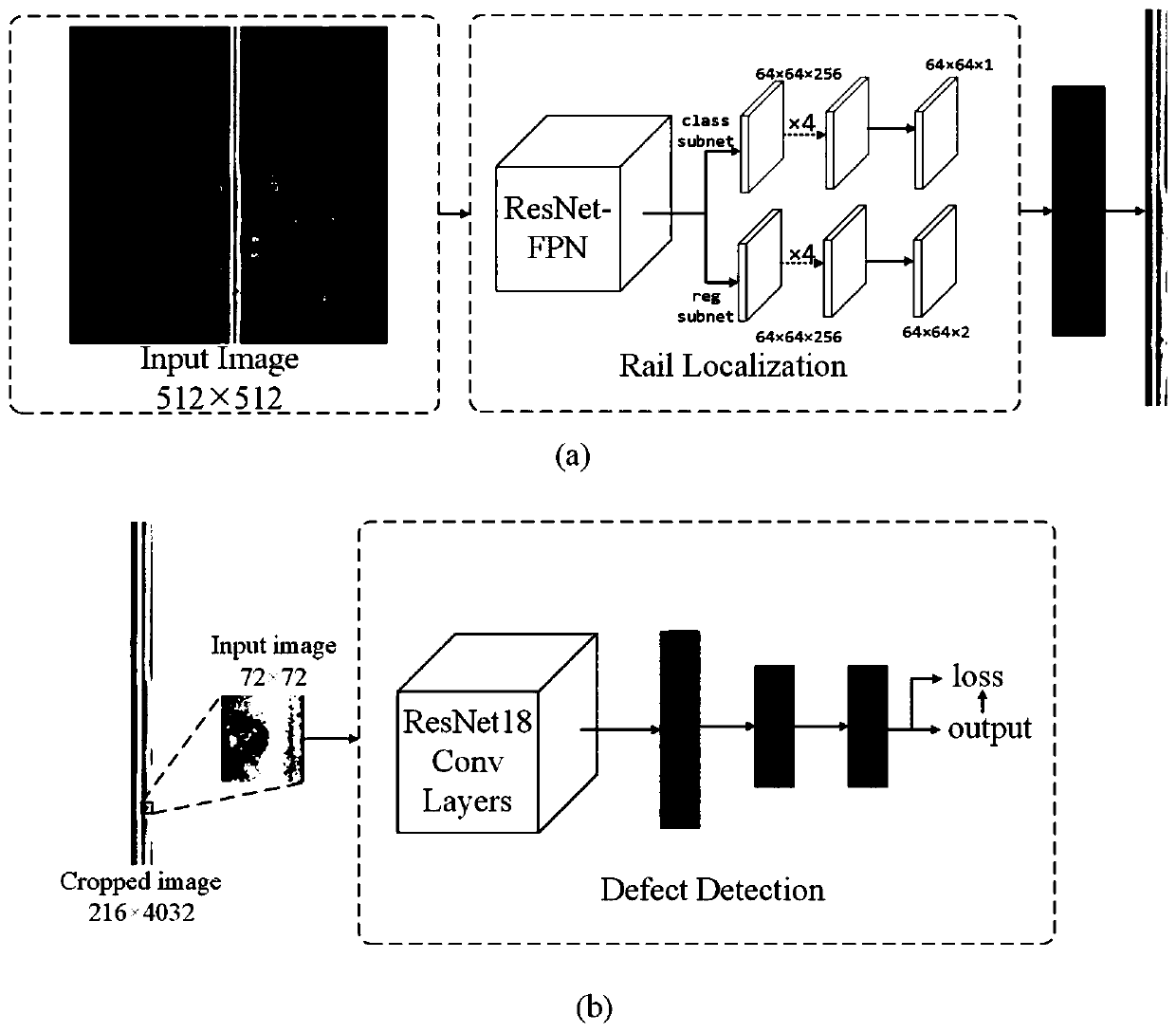

A defect detection and railway track technology, applied in the direction of optical defect/defect test, measuring device, character and pattern recognition, etc., can solve problems that threaten the normal running of trains, train derailment, railway breakage, etc., and achieve the effect of convenient, fast and efficient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

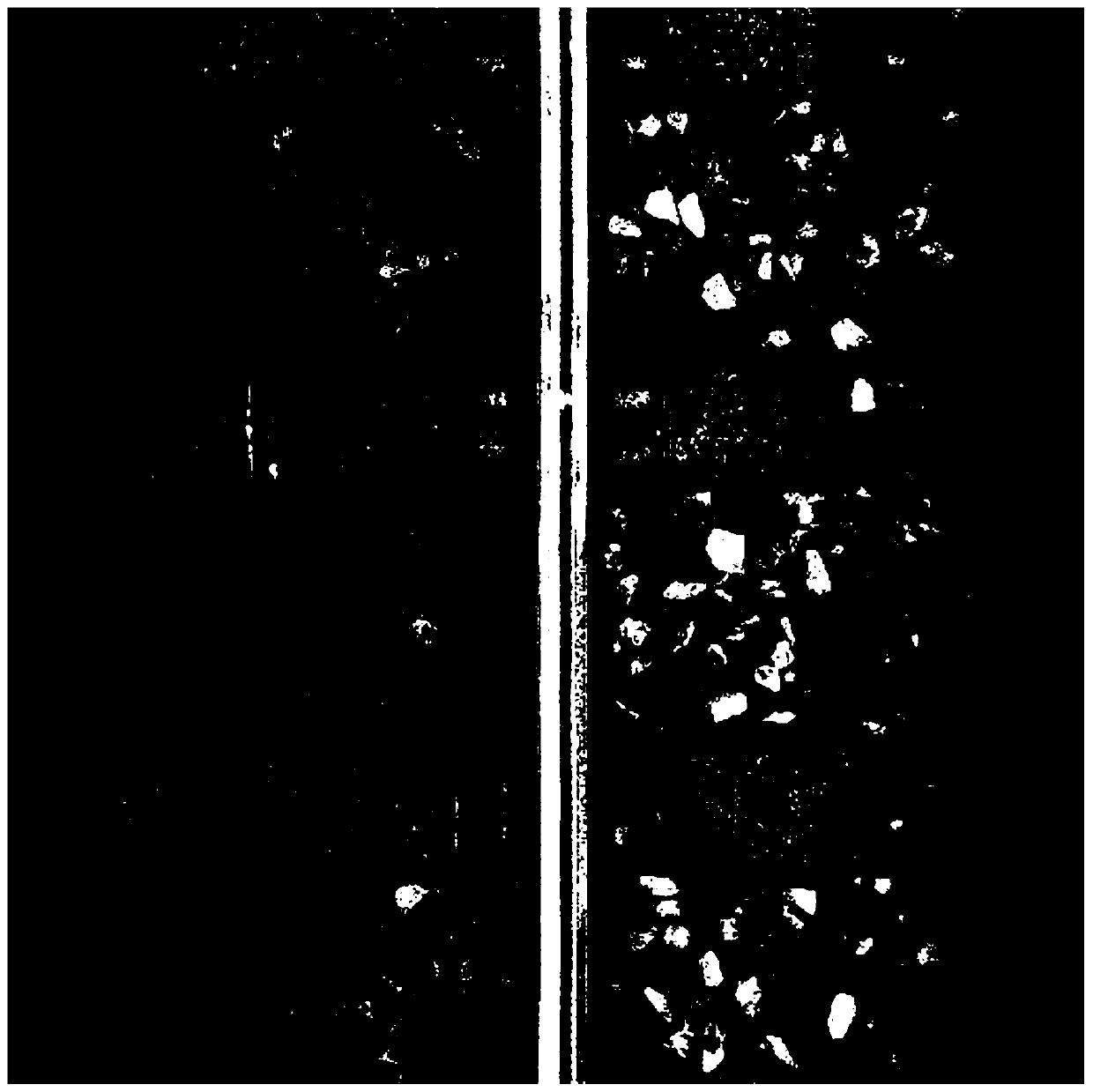

Image

Examples

Embodiment Construction

[0067] In order to make the above objects, features and advantages of the present application more obvious and comprehensible, the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0068] At present, there are mainly three methods for detecting railway track defects: the first is manual inspection, and the railway department arranges inspectors to periodically inspect along the railway line and replace the damaged track. However, in real life, the railway mileage that needs to be inspected is often very large. In order to ensure the safety along the railway, a large number of professional inspectors are often required to ensure the quality of the inspection, which will consume a lot of human resources. Moreover, the manual inspection method also needs to consume a lot of time and resources of the inspection personnel, and cannot perform quality inspection on the inspection results. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com