Chiller outdoor unit

A technology for outdoor units and refrigerators, applied in electrical components, cooling/ventilation/heating transformation, heating methods, etc., can solve problems such as insufficient cooling of heat-generating components, inability to fully exert cooling performance, etc. The effect of suppressing the degradation of cooling performance and the reduction of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

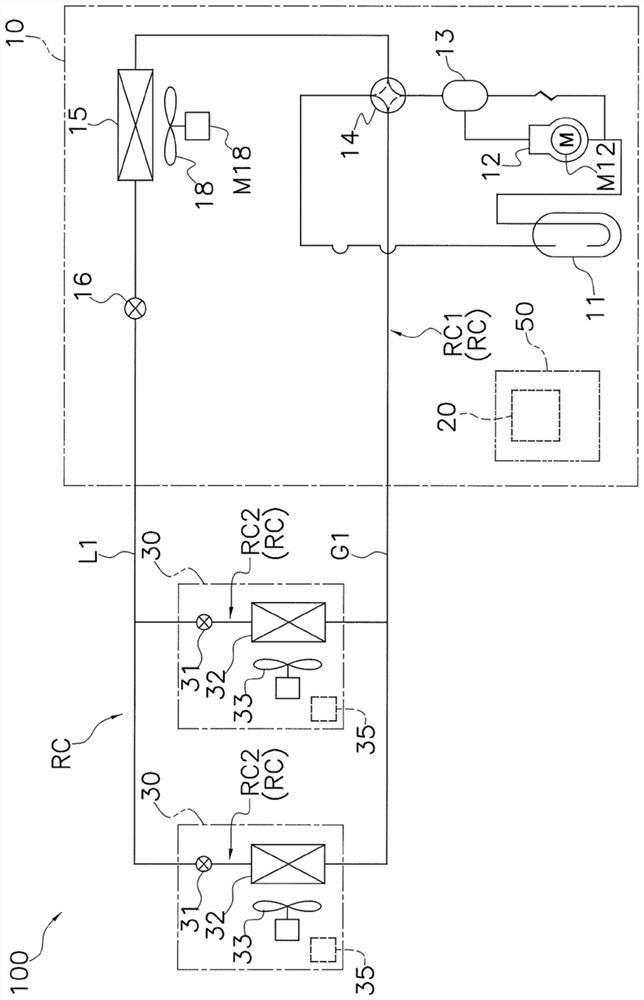

Method used

Image

Examples

example 2

[0254] In the above-described embodiment, the first cooling unit body portion 82 (the fin holding portion 821 ) has an area larger than that of the first opening 52 a when viewed from the front or back (when viewed from the front-rear direction), and is provided accordingly. In order to block the 1st opening 52a, the space outside the distribution box 50 is divided into the internal space SP. In this regard, it is preferable to configure and arrange the first cooling unit body portion 82 as described above from the viewpoint of reliably shielding the heat pipe 83 from the outdoor air flow AF and suppressing deterioration of the weather resistance of the heat pipe 83 .

[0255] However, as long as the heat pipe 83 does not extend from the space (internal space SP) in the distribution box 50 to the air supply space S1 outside the electronic component box, and the effect described in (9-1) above is not contradictory, the first cooling The configuration of the unit body portion 82...

example 3

[0257] The configuration of the first cooling unit 80 is not limited to that shown in the above-described embodiment, and can be appropriately changed according to design specifications and installation environments.

[0258] For example, in the above-described embodiment, the front surface portion 822 a of the first cooling unit body portion 82 (the heat pipe holding portion 822 ) is interposed between the heat pipe 83 and the high heat-generating electrical component 65 . In this regard, by avoiding direct contact with the high-heat-generating electrical components 65, deformation, damage, deterioration, corrosion, etc. of the heat pipes are suppressed. An intervening object is set between 65 to avoid direct contact between the two. However, as long as the effect shown in (9-1) above can be achieved (the heat pipe 83 is shielded by the space outside the distribution box 50 and the weather resistance of the heat pipe 83 is suppressed from being lowered), the heat pipe 83 and ...

example 12

[0280] In the above-mentioned embodiment, the high-heat-generating electrical component 65 is described as an example of a power module including a plurality of power devices. However, the high heat-generating electrical component 65 is not limited to this, and any electrical component that generates heat when energized may be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com