Brush holder for a rotating electrical machine

A technology for rotating electrical machines and brush holders, applied in electrical components, electromechanical devices, electrical components, etc., can solve problems such as grounding offset, electromagnetic compatibility problems, and paths that are not direct, so as to improve reliability and improve electromagnetic compatibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The embodiments described below are in no way limiting; in particular, if such a selection of features is sufficient to provide a technical advantage, or to distinguish the invention from the prior art, it will be possible to conceive of including only the selection of features described below, in conjunction with all Variations of the invention isolated from the other features described. In particular, all variants and all embodiments described can be combined with one another, if such a combination is not objectionable from a technical point of view. In this case, this will be referred to in this description.

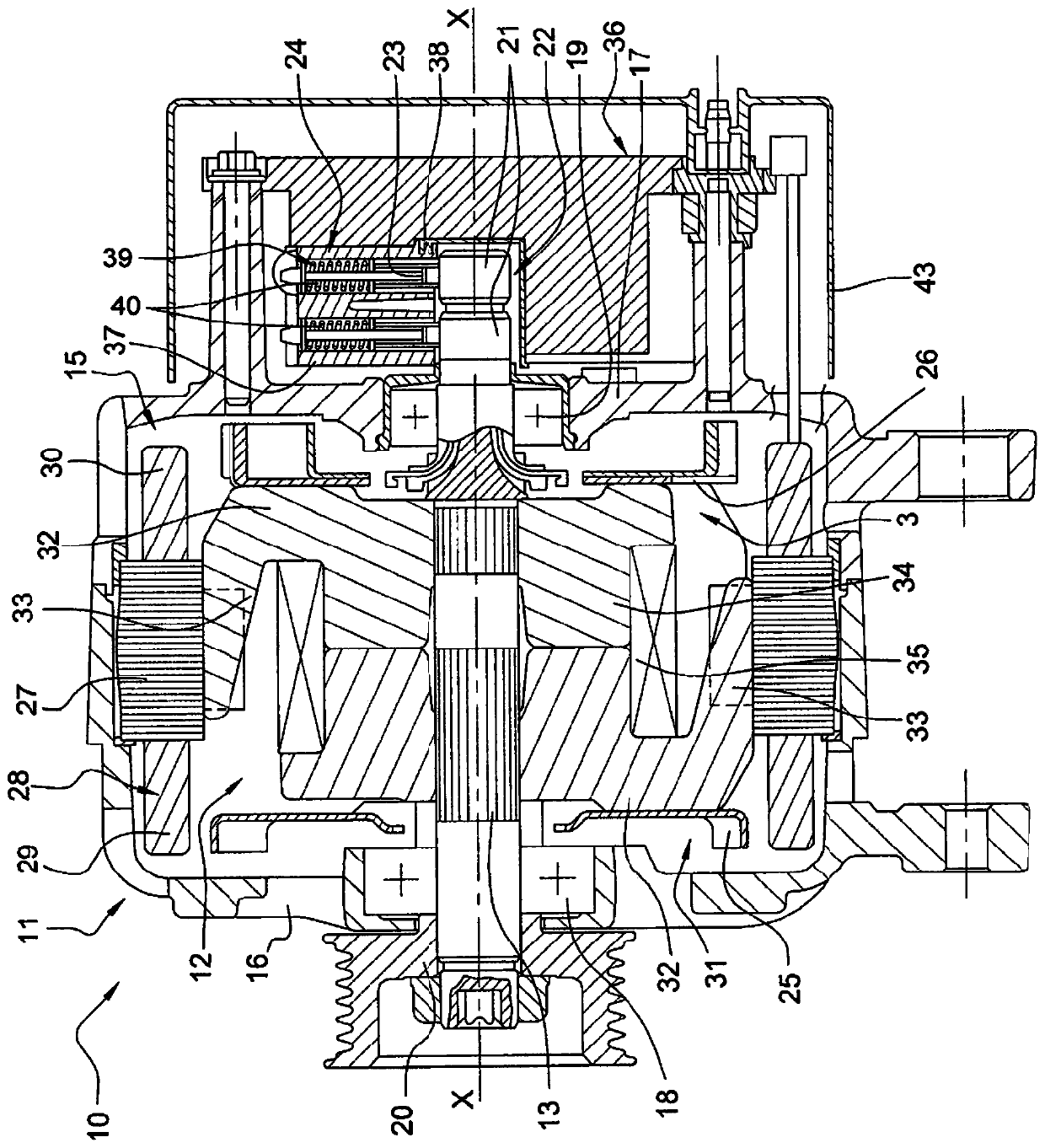

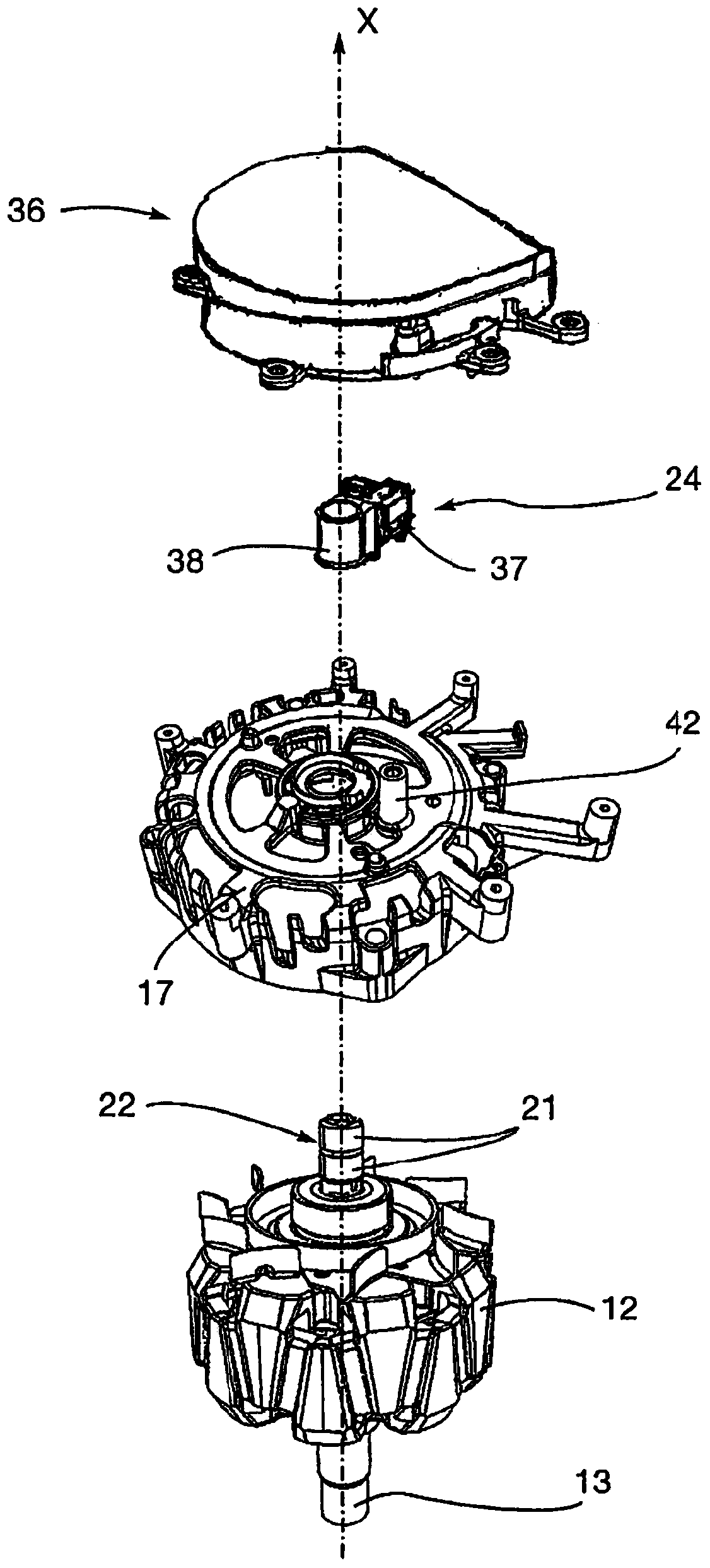

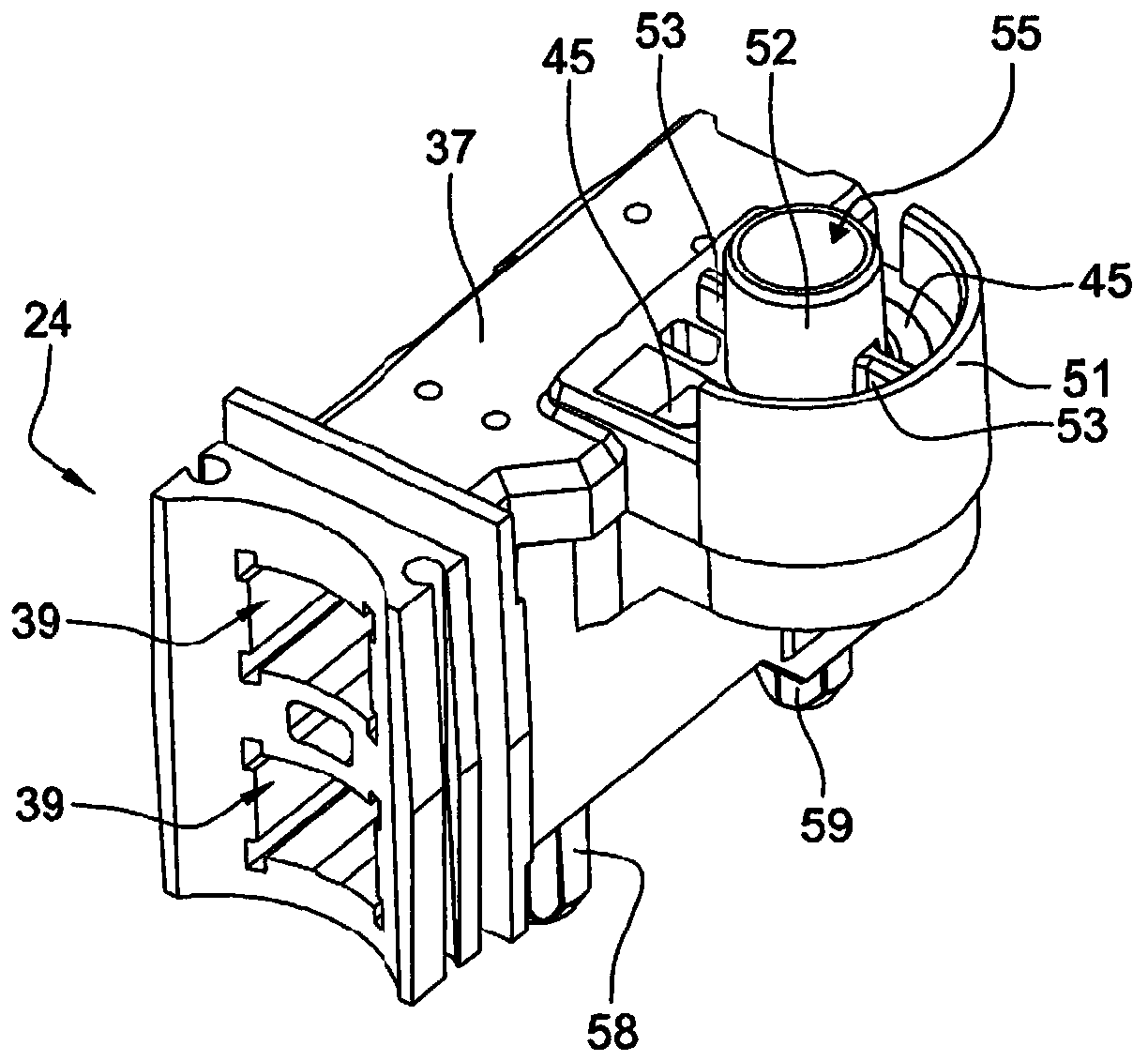

[0054] figure 1 A compact multiphase rotating electric machine 10 is shown, especially for motor vehicles. The rotating electrical machine 10 converts mechanical energy to electrical energy in alternator mode, and can be operated in motor mode to convert electrical energy to mechanical energy. The rotating electric machine 10 is, for example, an alternator, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com