Oxygen lance straightening machine

A technology for straightening racks and oxygen lances, which is applied in the field of oxygen lance straightening machines, can solve the problems of high risk, low degree of mechanization, and high difficulty in oxygen lance straightening, achieving safety, saving land area, The effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in combination with the accompanying drawings and specific embodiments.

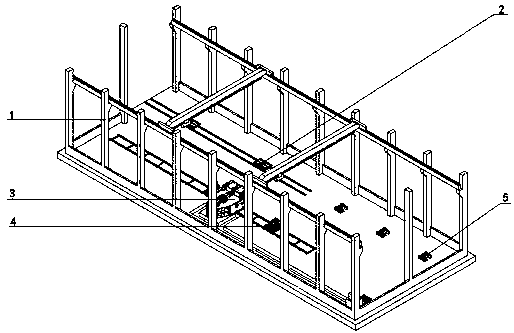

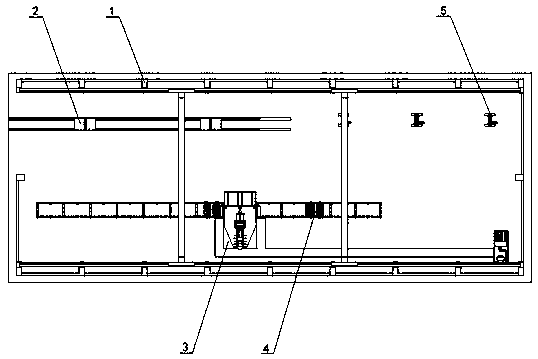

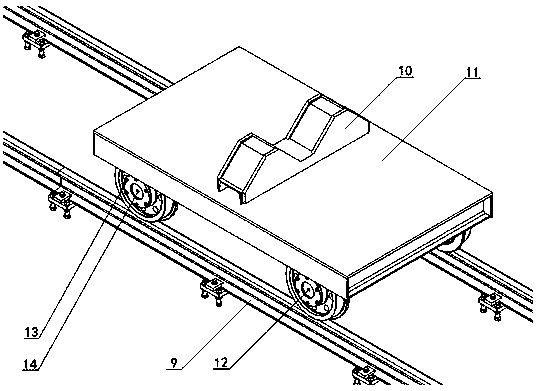

[0029] like figure 1 As shown, an oxygen lance straightening machine includes a complete machine frame 1, an oxygen lance entry and exit station device 2, an oxygen lance straightening device 3, a liftable track trolley 4, and an oxygen lance rotating platform 5; the complete machine frame 1 Installed around the workshop, the oxygen lance entry and exit station device 2 is placed on the left side of the machine frame 1 for the entry and exit of the oxygen lance, and the oxygen lance rotating platform 5 is placed on the right side of the oxygen lance entry and exit station device 2 for For manual repair, the oxygen lance straightening device 3 is placed parallel to the oxygen lance entry and exit station device 2 and the oxygen lance rotating platform 5 , and the liftable track trolley 4 is placed on both sides of the oxygen lance straightening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com