A method for removing heavy metal chromium and nickel in aluminum slag

A heavy metal, aluminum slag technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve problems such as aluminum loss, and achieve low aluminum loss, simple method and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

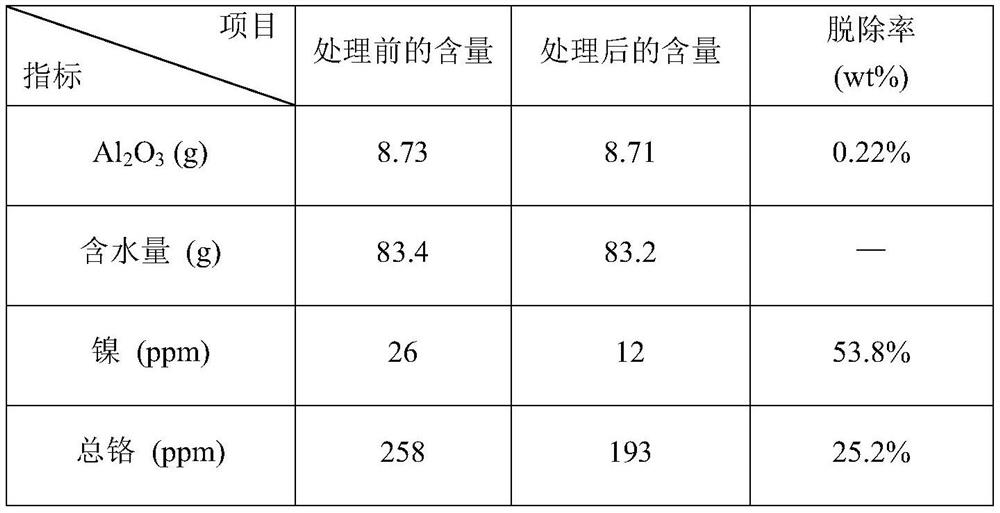

Embodiment 1

[0058] (1) Add 100g of wet aluminum slag (moisture content is about 80%) in the three-necked flask with built-in magnetic stirring rotor, then add 150g tap water in the three-necked flask, then place the three-necked flask in a constant temperature magnetic stirring water bath, And turn on the magnetic stirring, and stir at a speed of 100 r / min for about 15 minutes, so that the larger aluminum slag is evenly dispersed in the aqueous solution.

[0059] (2) Continue to slowly add ammonia water dropwise in the three-necked flask so that the pH value of the entire mixed solution is 10.

[0060] (3) Install a condenser tube on the middle port of the three-necked flask, and seal the other two ports of the three-necked flask with corresponding glass stoppers, then turn on the tap water for condensation cycle, and set the heating temperature to 50°C, and then turn on the constant temperature magnetic stirring Heat the water bath to the preset water bath temperature, maintain the water...

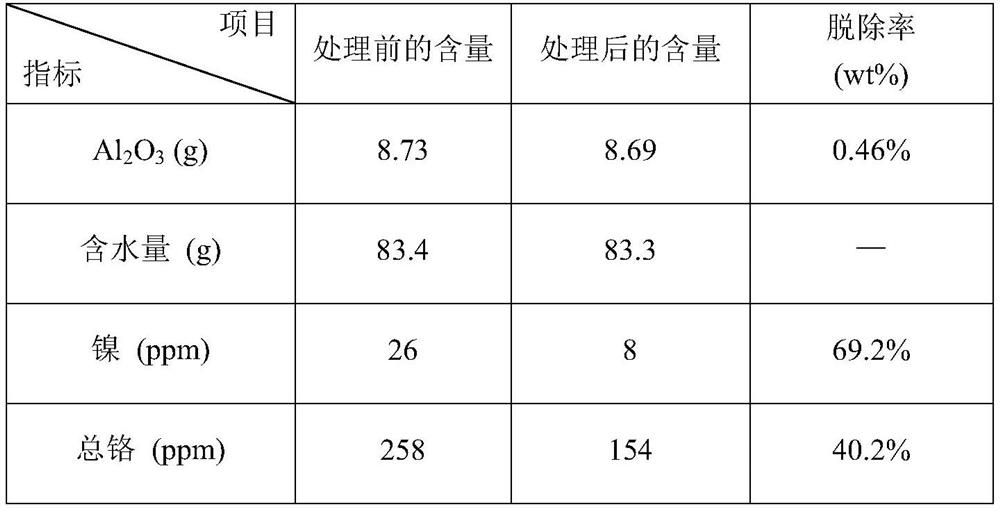

Embodiment 2

[0068] (1) Add 100g of wet aluminum slag (moisture content is about 80%) in the three-necked flask with built-in magnetic stirring rotor, then add 150g tap water in the three-necked flask, then place the three-necked flask in a constant temperature magnetic stirring water bath, And turn on the magnetic stirring, and stir at a speed of 100 r / min for about 15 minutes, so that the larger aluminum slag is evenly dispersed in the aqueous solution.

[0069] (2) Continue to slowly add ammonia water dropwise into the three-necked flask so that the pH value of the entire mixed solution is 10.5.

[0070] (3) Install a condenser tube on the middle port of the three-necked flask, and seal the other two ports of the three-necked flask with corresponding glass stoppers, then turn on tap water for condensation cycle, and set the heating temperature to 45°C, then turn on the constant temperature magnetic stirring Heat the water bath to the preset water bath temperature, maintain the water bat...

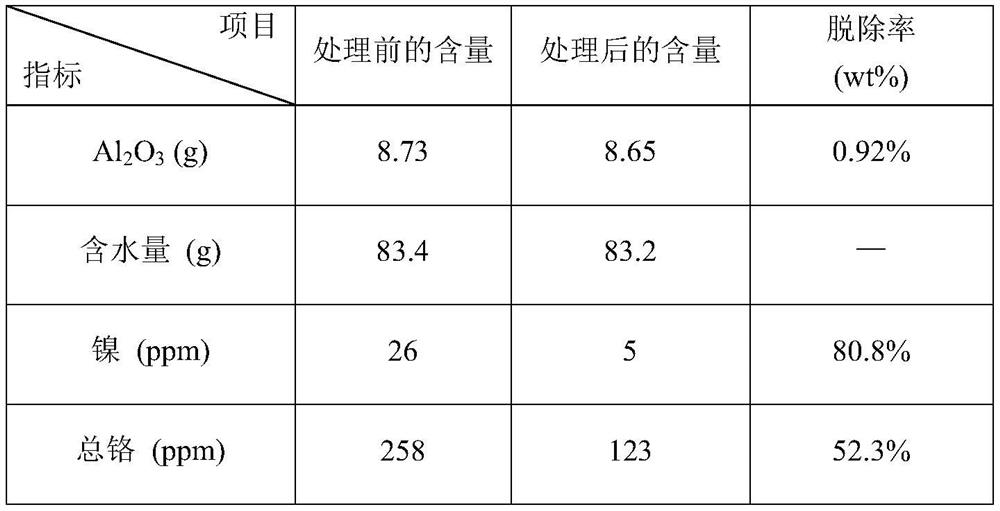

Embodiment 3

[0078] (1) Add 100g of wet aluminum slag (moisture content is about 80%) in the three-necked flask with built-in magnetic stirring rotor, then add 150g tap water in the three-necked flask, then place the three-necked flask in a constant temperature magnetic stirring water bath, And turn on the magnetic stirring, and stir at a speed of 100 r / min for about 15 minutes, so that the larger aluminum slag is evenly dispersed in the aqueous solution.

[0079] (2) Continue to slowly add ammonia water dropwise in the three-necked flask so that the pH value of the entire mixed solution is 11.

[0080] (3) Install a condenser tube on the middle port of the three-necked flask, and seal the other two ports of the three-necked flask with corresponding glass stoppers, then turn on the tap water for condensation cycle, and set the heating temperature to 40°C, and then turn on the constant temperature magnetic stirring Heat the water bath to the preset water bath temperature, maintain the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com