Heavy type catenary conveying system with moving machine

A conveying system and moving machine technology, applied in mechanical conveyors, conveyors, transportation and packaging, etc., can solve problems such as complex structures, and achieve the effects of compact trolley structure, saving land area, and convenient manufacturing and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

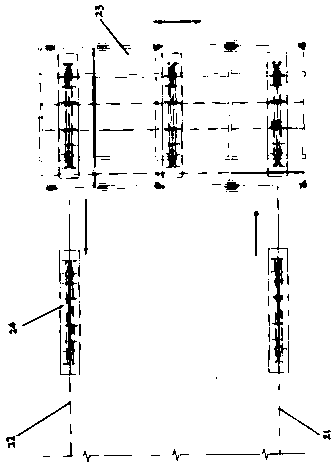

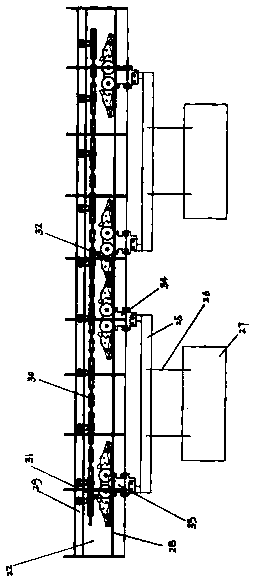

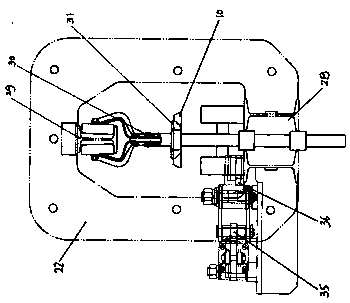

[0022] A heavy-duty catenary conveyor system with a traveling machine, comprising an outer horizontal catenary conveyor line 21 and an inner horizontal catenary conveyor line 22 on a closed-loop heavy-duty catenary conveyor line, and is set on the outer horizontal catenary conveyor line 21 There is an outer accumulation area, an inner accumulation area is set on the inner horizontal catenary conveyor line 22, and a transfer machine is arranged between the end of the outer horizontal catenary conveyor line 21 and the head end of the inner horizontal catenary conveyor line 22 23. On the heavy-duty catenary conveyor line, there are multiple groups of load-bearing trolleys 24. The load-bearing trolleys 24 are composed of left-side load-bearing trolleys 33 and right-side load-bearing trolleys 34 with identical structures. Between the suspension plate and the vertical suspension pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com