Aluminum gusset plate machining device

A technology of processing equipment and aluminum gussets, applied in metal processing equipment, perforation tools, manufacturing tools, etc., can solve the problems of isolation and low degree of automation, and achieve the effect of smooth material pulling and accurate rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

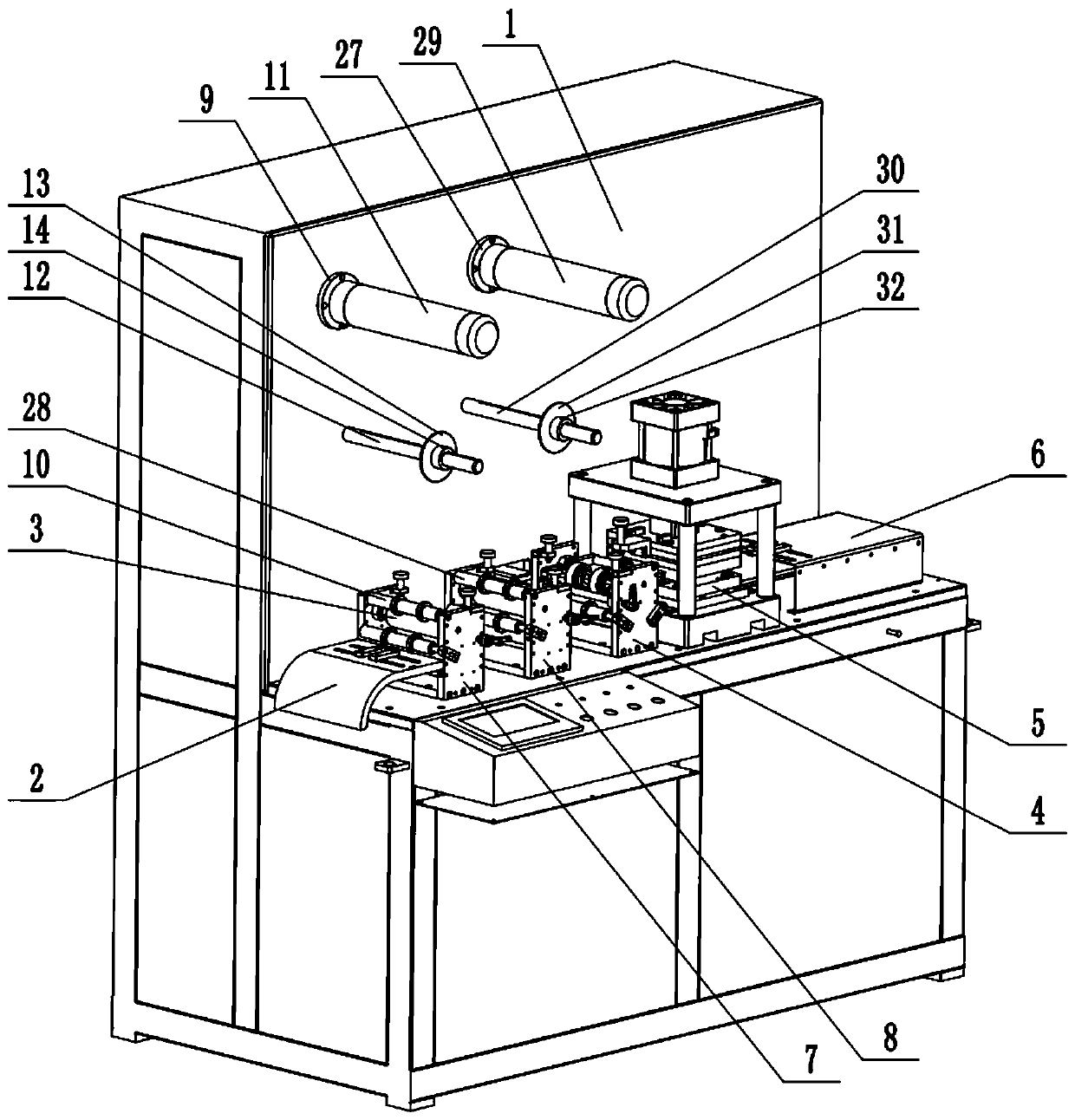

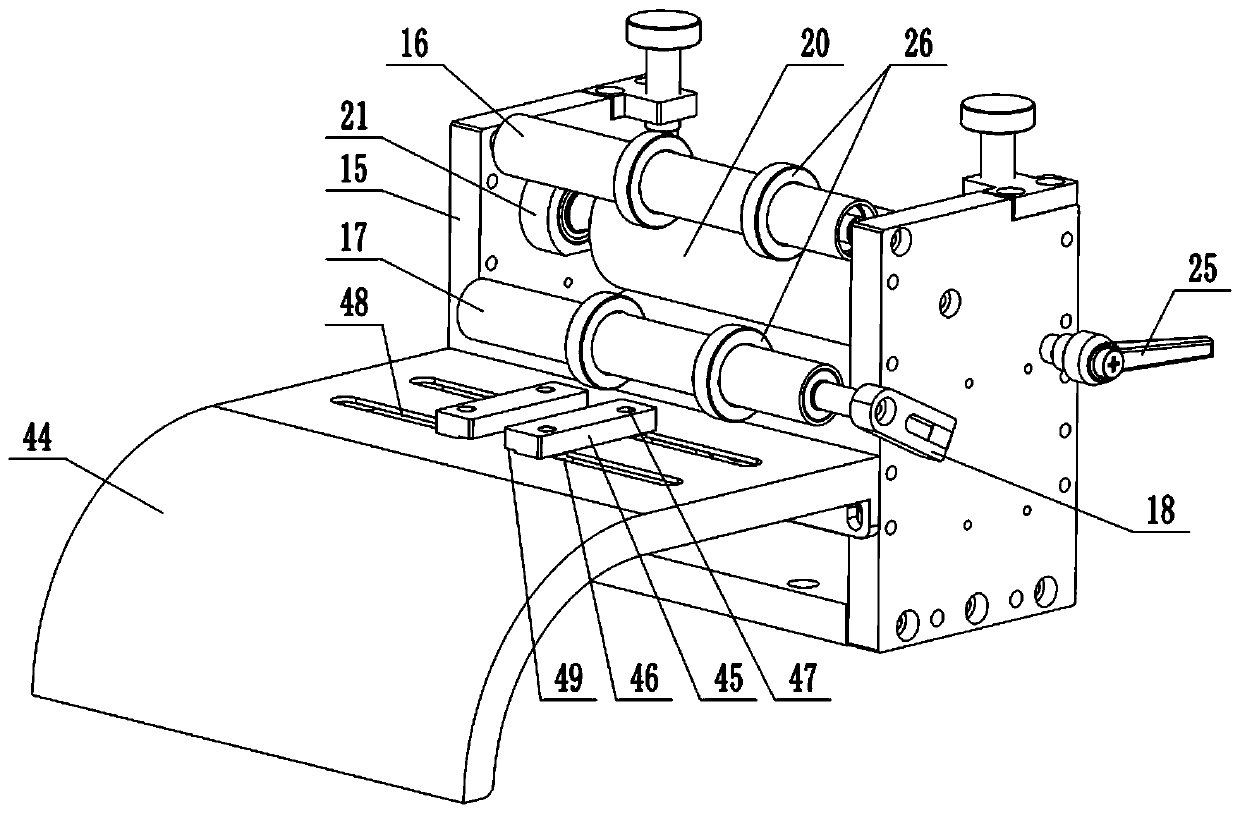

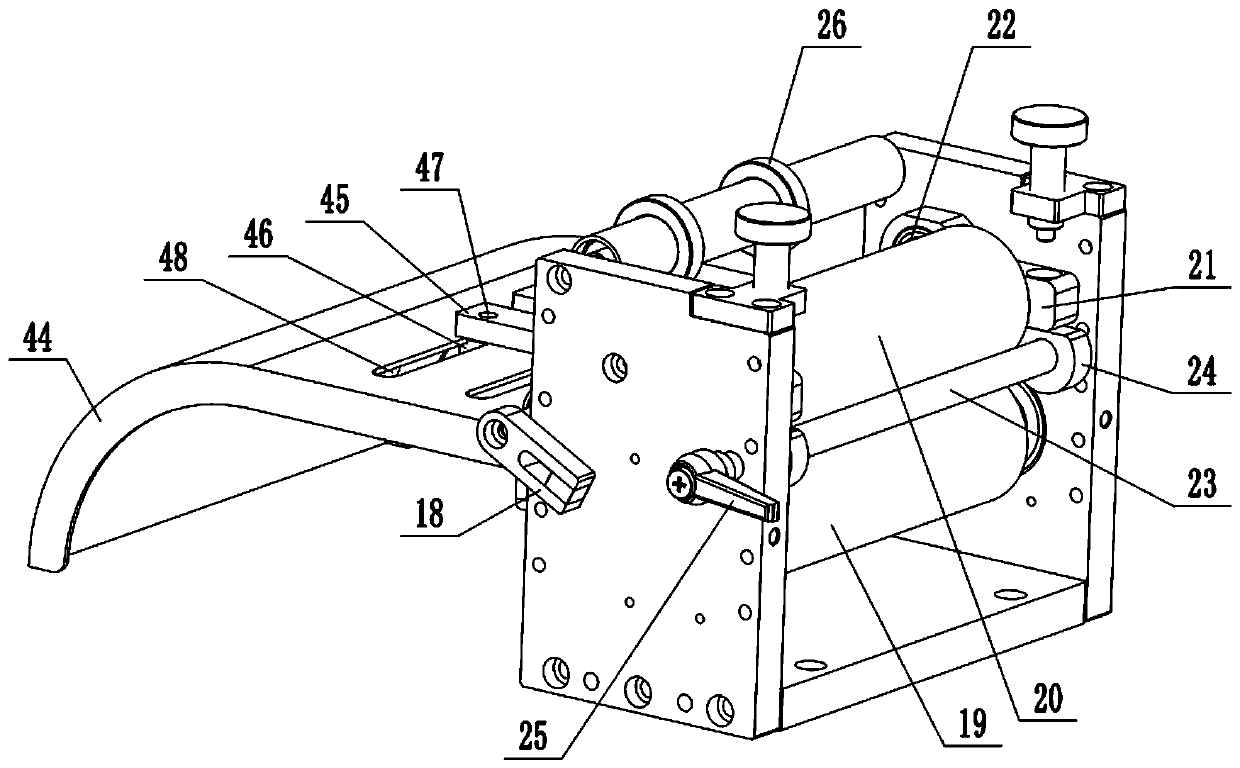

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12Shown, a kind of aluminum gusset plate processing equipment, it comprises chassis 1, feeding guide device 2, double-layer coating device 3, pulling material device 4, punching device 5, discharge guide device 6, described feed guide The device 2, the double-layer laminating device 3, the pulling device 4, the punching device 5, and the discharge guide device 6 are sequentially arranged on the chassis 1 from left to right; the double-layer laminating device 3 includes a first laminating mechanism 7 and the second film covering mechanism 8, the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com