Early warning device for waste blockage of continuously-blanking die

A technology of early warning device and blanking mold, which is applied in the direction of manufacturing tools, metal processing equipment, safety equipment, etc., can solve the problems of complex shape of blanking sheet, influence on production efficiency, waste accumulation and blockage, etc., so as to avoid equipment damage and other impacts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

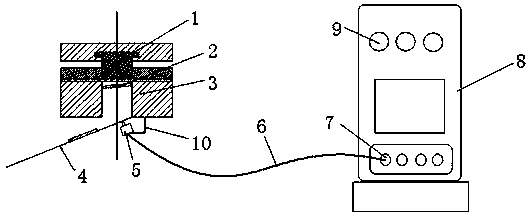

[0026] This embodiment provides an early warning device for mold waste clogging on a steel continuous blanking production line. The technical problem solved by the early warning device is the problem of blanking clogging that widely plagues automobile mold processing. The current method used is to configure a corresponding chute assembly at the blanking port of the mold equipment, and the chute assembly includes a roller platform with an auxiliary material sheet falling, and a metal plate with a smooth surface. The roller platform is generally used for guide sliding of smaller pieces. Such pieces have a small weight and are not easy to slide down along the plane. Larger pieces can directly use metal plates to slide down freely by the weight of waste materials. However, at the blanking port located in the middle of the mold, due to the special position and the complex shape of the waste, on the one hand, the operator cannot intuitively grasp the blanking situation; Gently, so t...

Embodiment 2

[0029] The difference between this embodiment and the first embodiment is that there are multiple mold waste clogging warning devices, which are respectively arranged at the bottom of the corresponding blanking chute 4 . At this time, the number of sensing elements, wires, relay controllers, and sound and light alarms all match the settings. The inductive element in this embodiment is a travel switch.

Embodiment 3

[0031] The difference between this embodiment and the first embodiment is that the sensing element is a pressure sensor.

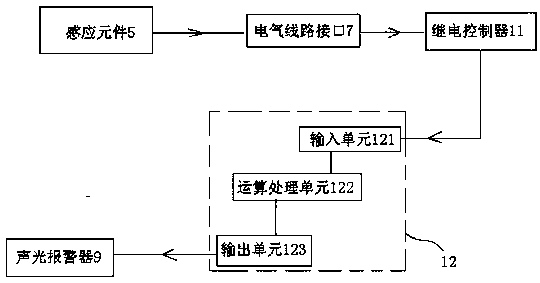

[0032] A kind of early warning device for continuous blanking mold waste blockage in the above embodiment, through the position matching of the internal waste chute assembly and the sensing element, the sensing element is connected with the relay controller through the wire, and the relay controller is connected with the pressure controller through the wire. The PLC controller of the machine is connected, and finally the sound and light alarm on the operation panel is driven by the PLC controller for sound and light alarm. The sensing element is used to monitor the blockage of the chute assembly, and the blocking signal is transmitted to the relay controller through the wire of the sensing element. The relay controller includes an array of relays. When the blocking signal is set, the relay line Including suction and closing, connect the 24V power supply an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com